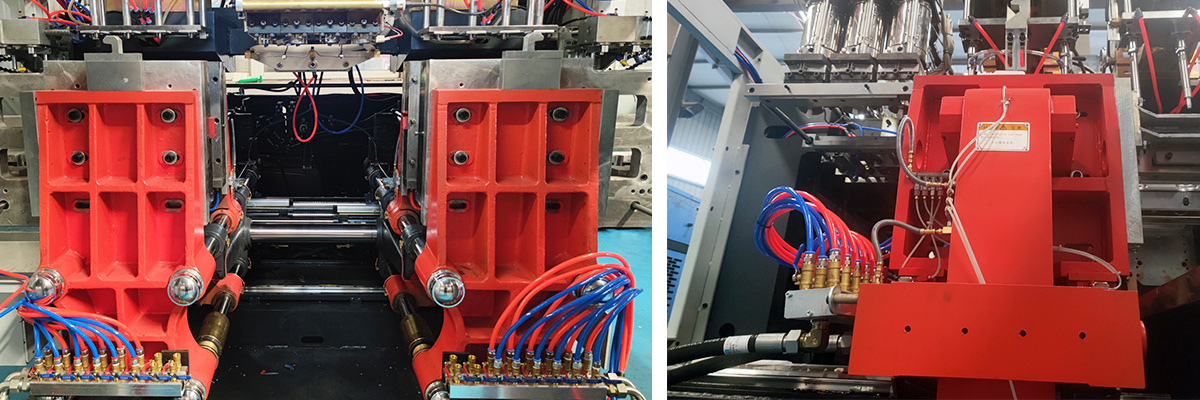

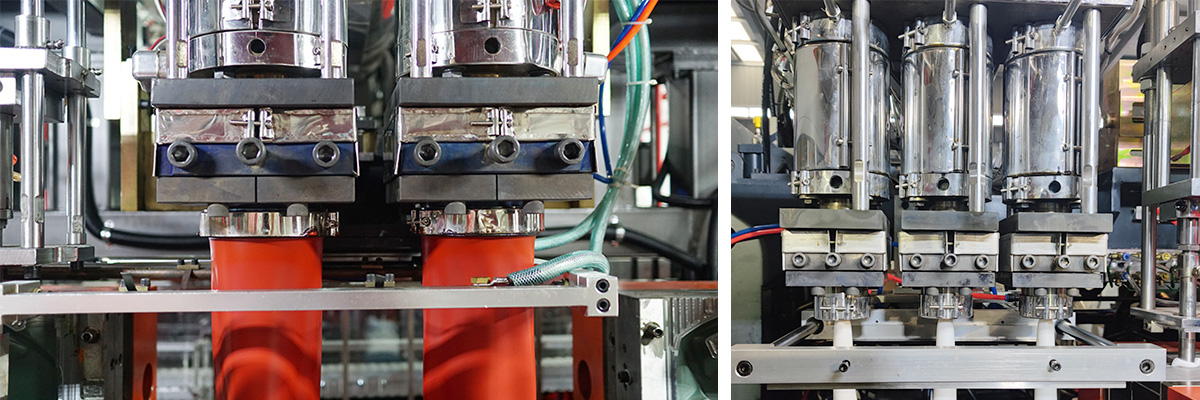

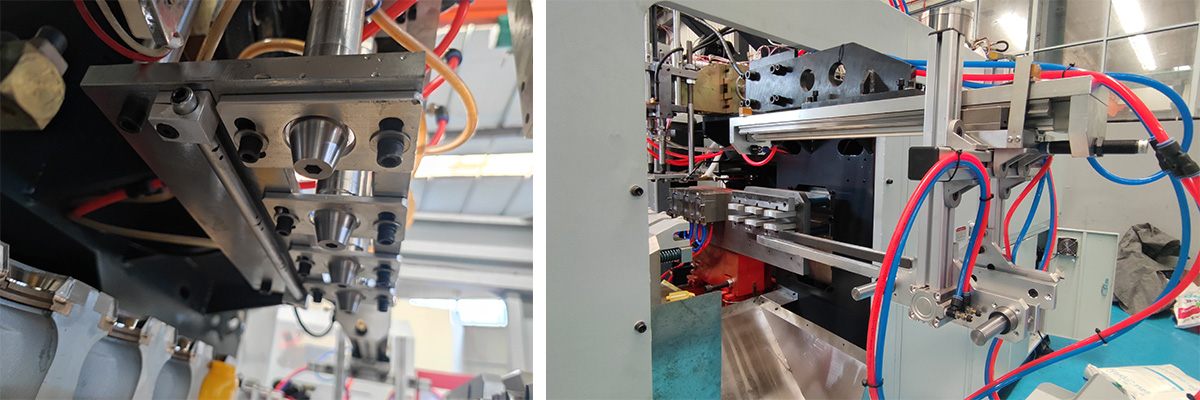

The extrusion blow molding machine adopts parallel carriage moving, with automatic lubricationsystem.The movements is stable and easy operate, two layerdie head is optional.This series machine is widely used infood packing, pharmacy and cosmetic area. It can choose single and double mode-shifting models to meet different output requirements. It can be equipped with single head, double head, four head, multi-layer head, double transparent line head and servo wall thickness control head to meet the requirements of different products.

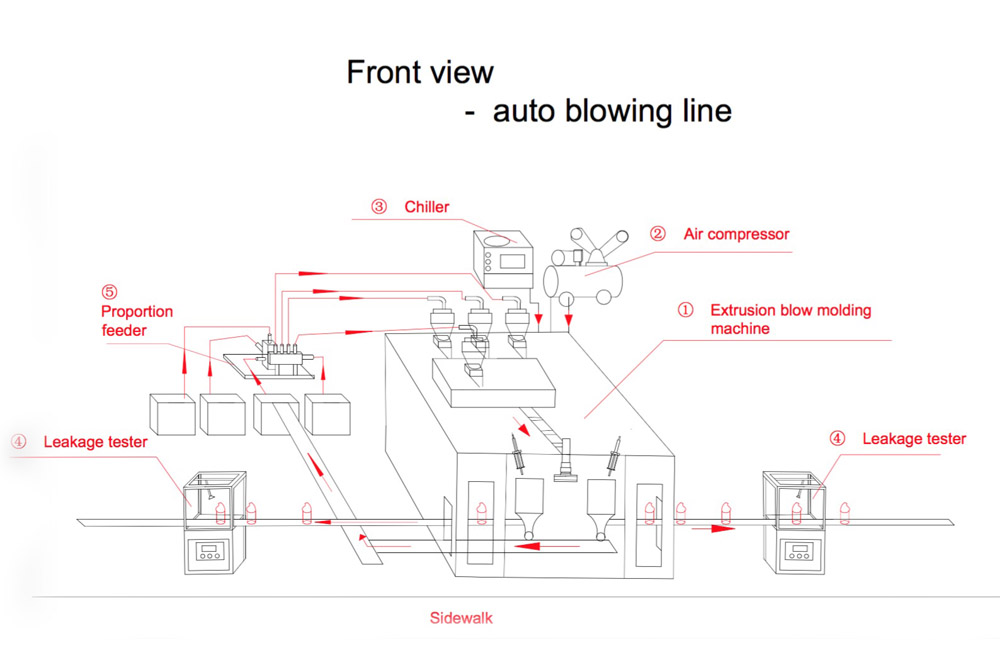

We shall supply whole production extrusion line including:

auto-loader (screw type or spring type or vacuum type)

chiller (water cooled type or air cooled type)

mixer

Compressor(piston type or screw type)

conveyor (for deflashing part or finished product )

others

Welcome to contact us if you are interested

SPECIFICATIONS | HJS80D |

Material | PE PP PVC PA... |

Max container capacity | 10L |

Number of die | 123,4,6 |

Machine Dimension(LxWxH) | 3.3*5.5*2.8m |

Total weight | 8.2ton |

CLAMPING UNIT |

|

Clamping force | 150kN |

Platen openning stokes | 220-620mm |

Carriage stroke | 540mm |

Max mould size(WxH) | 520*460mm |

EXTRUSION UNIT |

|

Screw diameter | 80mm |

Screw L/D ratio | 24 L/D |

(HDPE) Plasticizing capacity | 108kg/h |

Screw heating zone | 4 zone |

Screw heating power | 15.6kw |

Screw fan power | 0.14kw |

Extrusion motor power | 30kw |

DIE HEAD |

|

Die head heating zone | 3 zone |

Power of die heating | 13.5kw |

ENERGY CONSUMPTION |

|

Total power of machine | 74.98kw |

Power of oil pump motor | 11kw |

Air pressure | 0.6-0.8 Mpa |

Average energy consumption | 35kw |

Consumption compression air | 1.5m3/min |

Consumption cooling water | 40L/min |