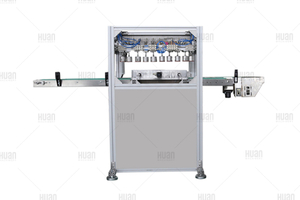

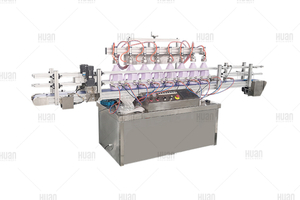

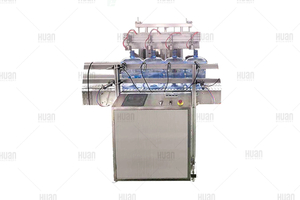

Tracking bottle leak test machine,High speed, 3000pc/hour

Products Character

Palletizing robots are divided according to their structure, and there are four common types: 1. Cartesian coordinate palletizing robot; 2. Palletizing robot with full joint structure; 3. Palletizing robot with parallelogram structure; 4. Linear horizontal multi-joint palletizing robot. These four types of palletizing robots are used in different palletizing occasions, which will be introduced separately below.

Cartesian coordinate palletizing robot, also known as truss palletizing robot or gantry palletizing robot, is based on the XYZ Cartesian coordinate system as the basic mathematical model, and the single-axis robotic arm driven by servo motors and stepping motors is the basic work unit. Arrive at any point in the XYZ three-dimensional coordinate system and follow a controllable motion trajectory.

The full-joint structure palletizing robot has four degrees of freedom, that is, four rotating joints. It has strong applicability and is widely used in the palletizing of cartons, plastic boxes, bottles, bags, barrels, film-packed products and filling products. , The structure design is simple, the action is stable and reliable, the stacking process is completely automatic, and no manual intervention is required during normal operation.

The parallelogram-structured palletizing robot is enlarged by the complex hinge structure through two linear axes, which not only has a large number of parts, but also has complicated installation. Because there is no need for algorithm support, most low-end palletizing robots use this architecture as a prototype.

The linear horizontal multi-joint palletizing robot has the same stability and high efficiency as the full-joint robot, and has the same cylindrical coordinate system as the parallelogram structure palletizing robot, and also has the same low cost as the right-angle palletizing robot structure.