1. who are we?

We are based in Jiangsu, China, start from 2011,sell to Africa(00.00%),Western Europe(00.00%),North America(00.00%),South America(00.00%),Southeast Asia(00.00%),Mid East(00.00%),South Asia(00.00%). There are total about 5-10 people in our office.

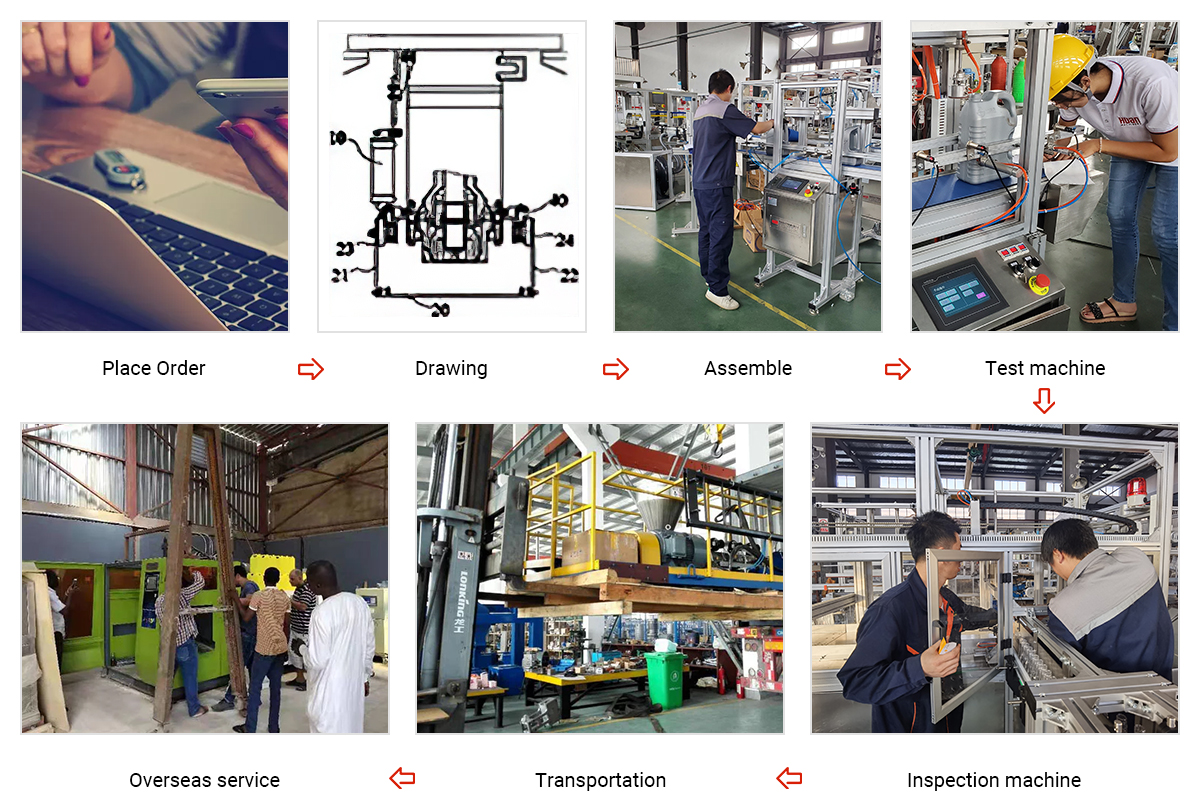

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

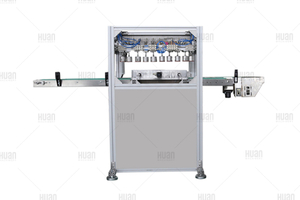

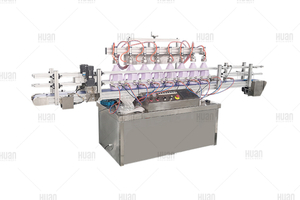

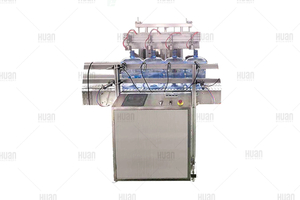

3.what can you buy from us?

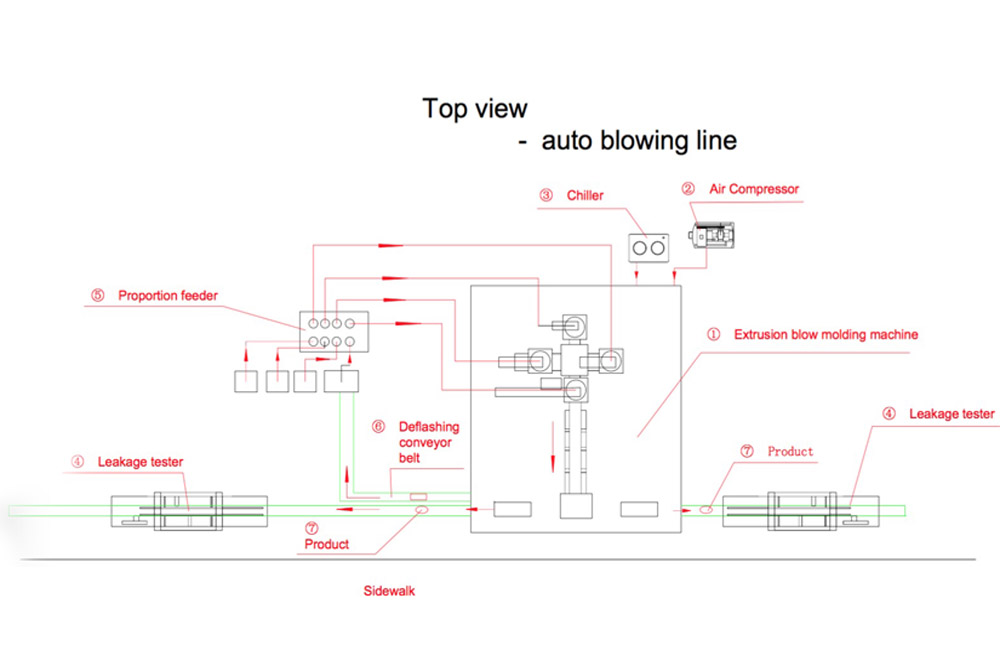

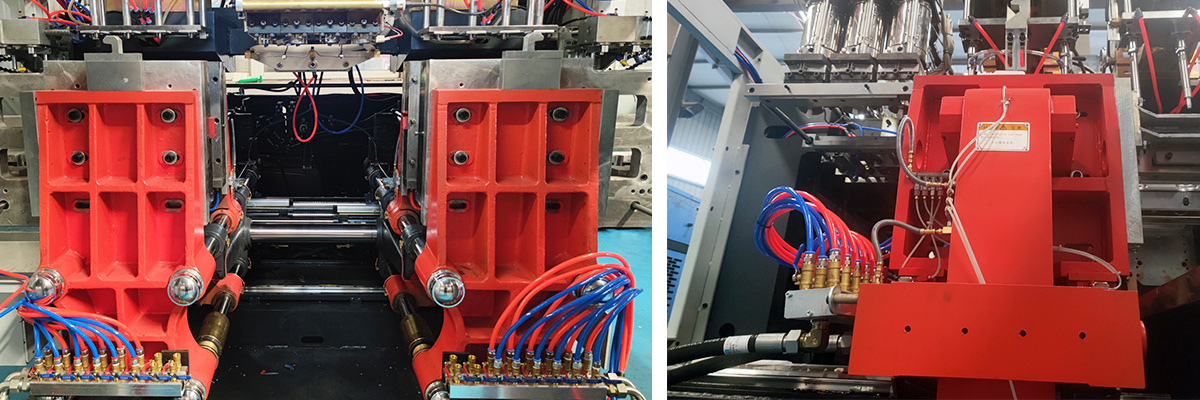

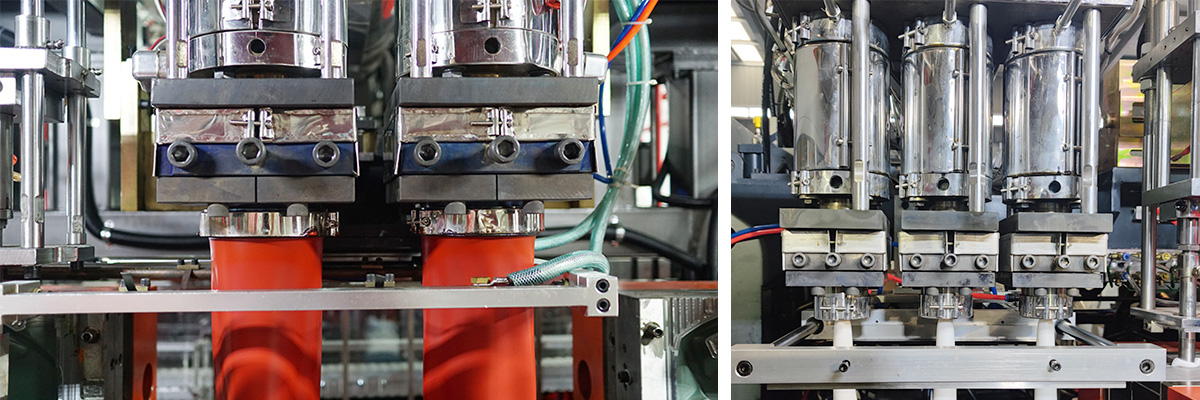

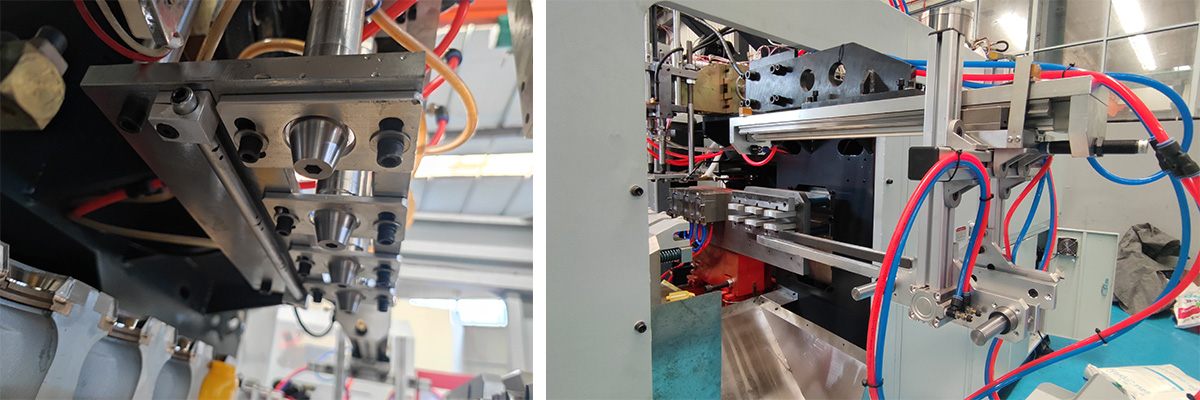

Extrusion Blow Molding Machine and Related Auxiliary Machines,Injection Molding Machine and Related Auxiliary Machines

4. why should you buy from us not from other suppliers?

More than 12 years manufacturing and exporting experience. We are a company with producing and exporting as well. We have clients to all over the world, accordingly we know each market well. My factory is near Shanghai airport with convenient traffic.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese,Spanish