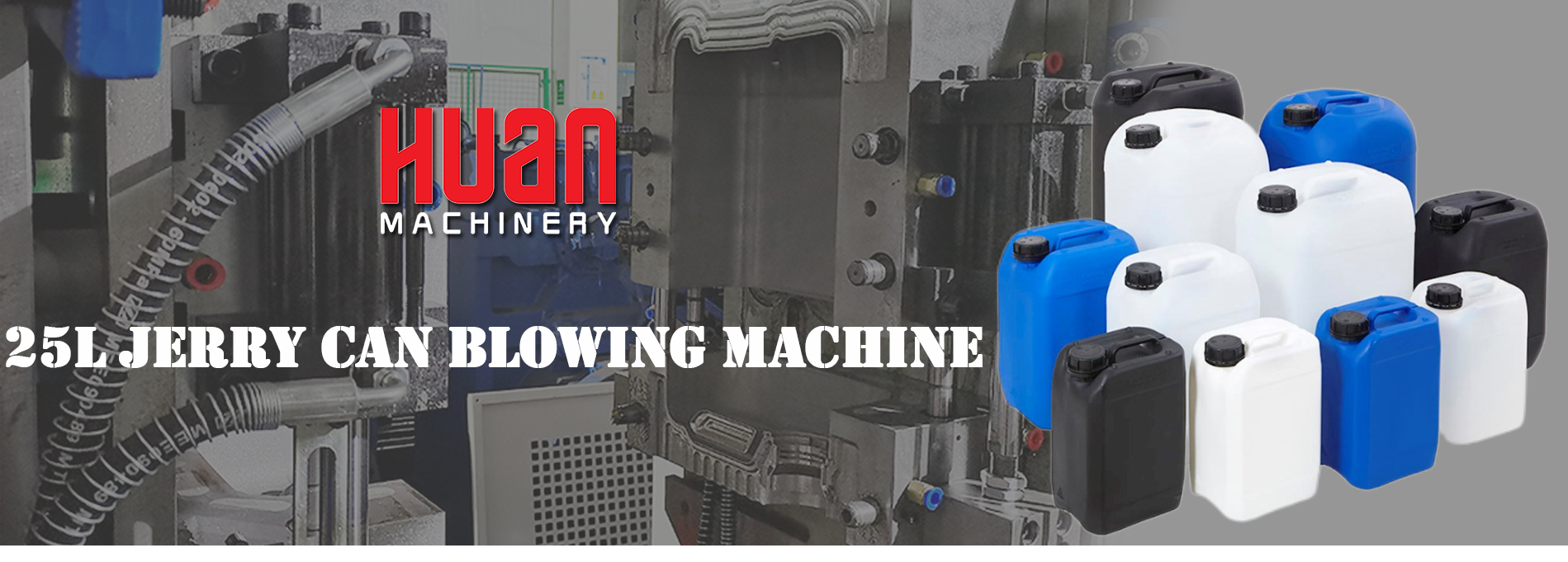

Economical type

Whole production line of extrusion blow molding machine is economical, suitable for no high capacity investor,producing 25L 30l 60L jerry can ,plastic drum ,hdpe barrel ,open top drums. | Mature technology

The blow molding machine is with accumulator head, the technology is mature. Huan machinery team has rich experiences,the blow molding machine is running stably. |

Wide range

It can produce max. 60L stack jerry can.Besides, this 60L blow molding machine also can produce top open drum,suitable for chemical industry, food industry, etc. | Servo system

The blow molding machine high energy saving operation, can Save the power consumption of 30%-40%. |

The extrusion blow molding machine is a mature design model for producing 10L to 60L jerry can, even top open drum.

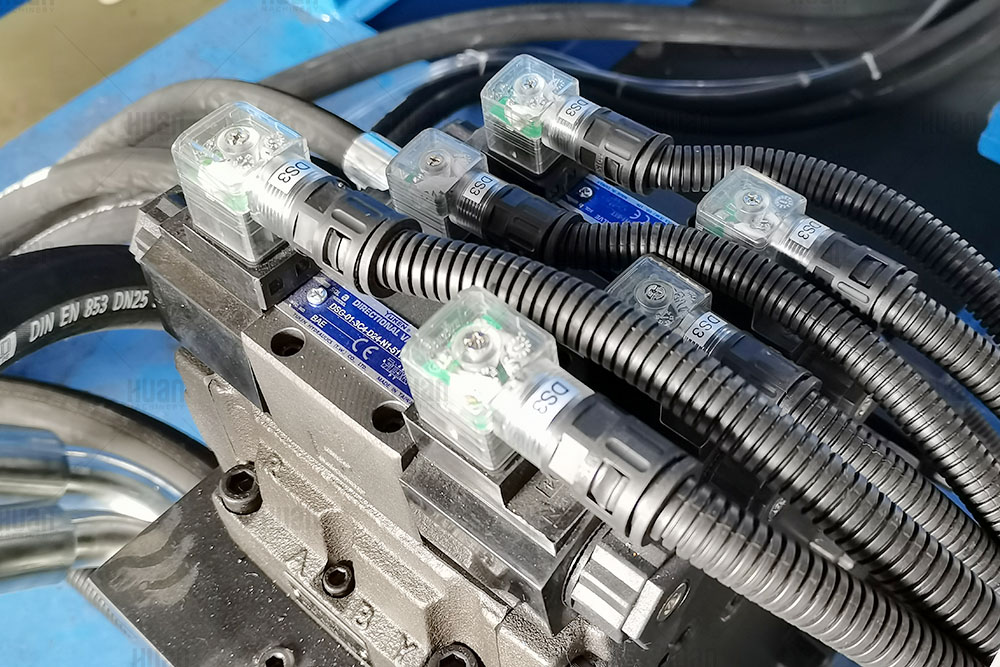

It is composed of extrude system, accuulating head, clamping system, control &electricity box,hydraulic system.

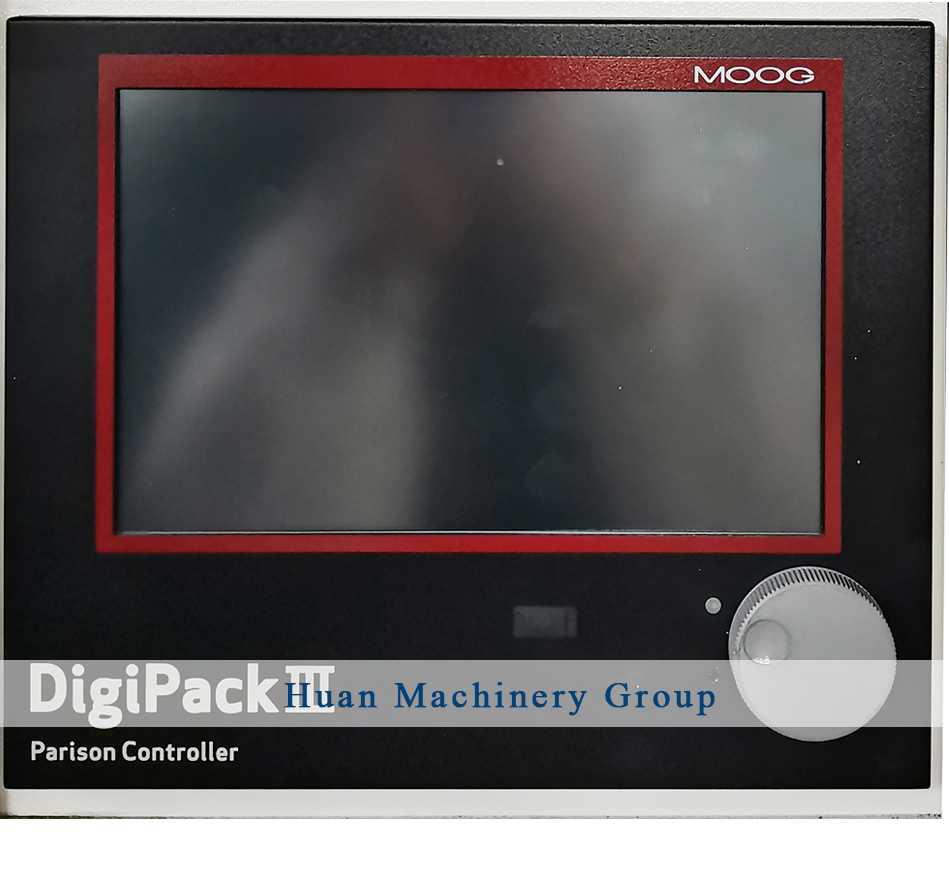

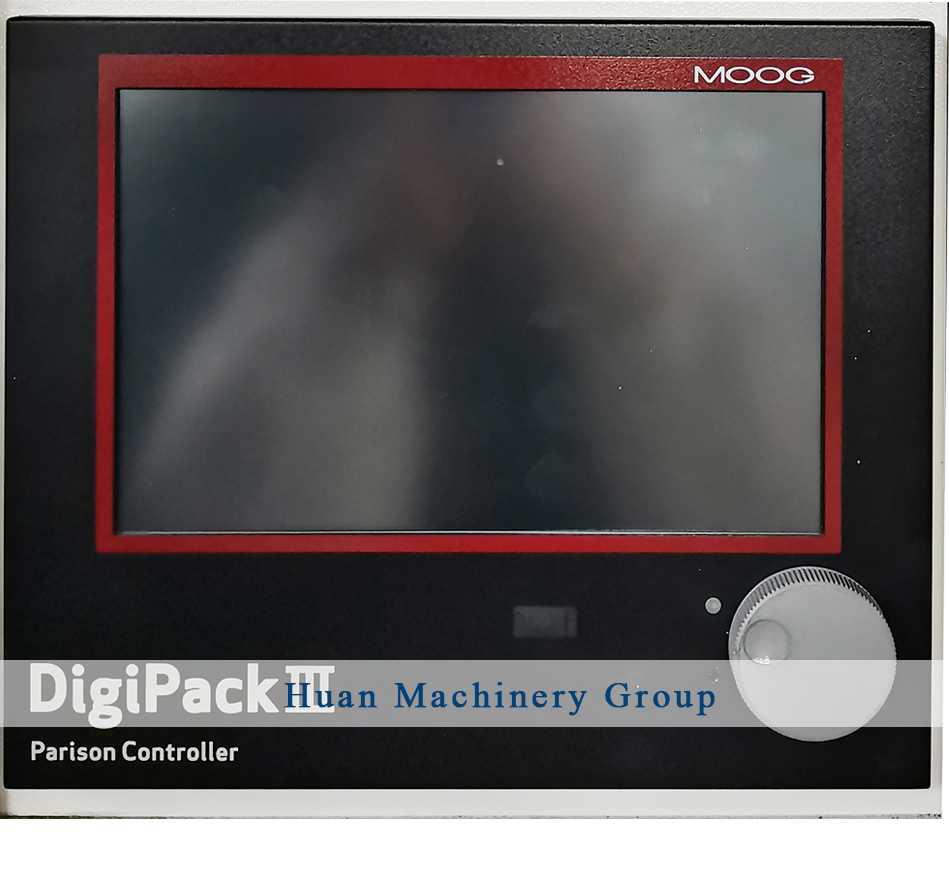

Parison control system

Blow molding machine adopts MOOG wall thickness control system,controling the thickness of parison precisionly, get the more strong jerrycan.

Hydraulic servo system

Sumitomo servo pump, Phase servo motorand Delta servo drive, this system can save30% to 40% power than Ac system.

Machine model | BSM80N-30L | BSM90N-60L |

Prdouct Capacity | 25L 30L 35L 50L 60L plastic drums |

Max product volume | 30L | 60L |

Extruders | 80mm | 90mm |

Main Drive | 30kw | 37kw |

Max. Extrusion Output | 125kg/hr | 145kg/hr |

Clamping Force | 230KN | 320KN |

Average Energy Consumption | 30kw | 39kw |

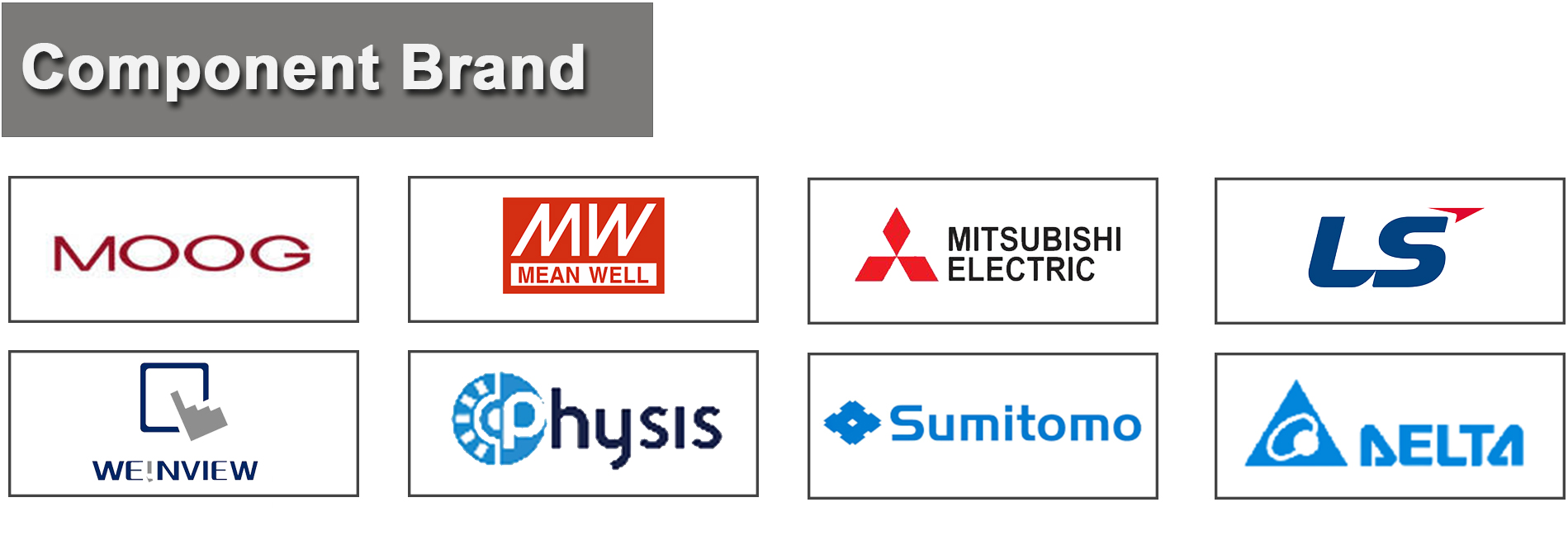

Our 30L 60L extrusion blow molding machine, parts are used in the world famous brands such as Mitsubishi, Sumitomo, MOOG, etc., to maintain the stable operation of the machine.

This accumulating blow molding machine is for the production of most of stack containers. it iswith mature technology design, and produce out the good quality jerrycan for chemicals, foodand agrochemicals, make sure the safe storage and transportation of various liquids.

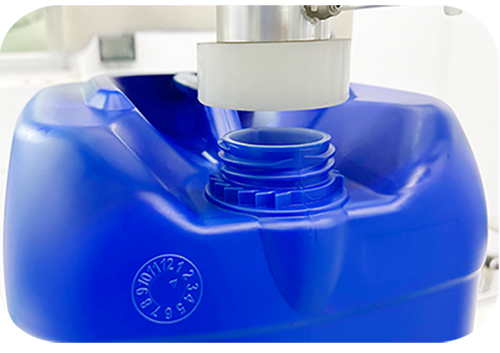

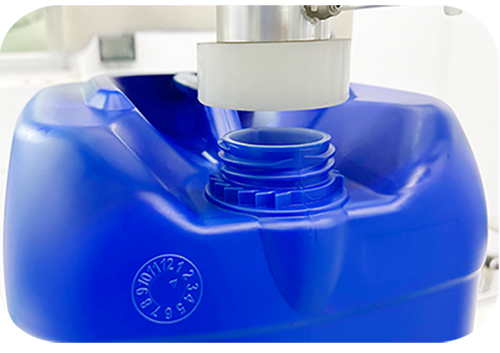

Blowing part:

The blow molding machine adopts bottom blow pin and material support, gogdmolding effect, and easy for changing the mold.

Feeding part:

The production line adopts the proportional weighing machine, provide accurate materials ratio.

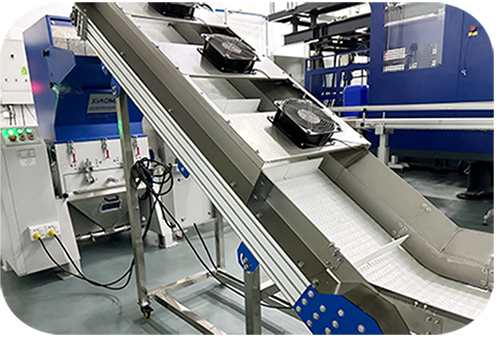

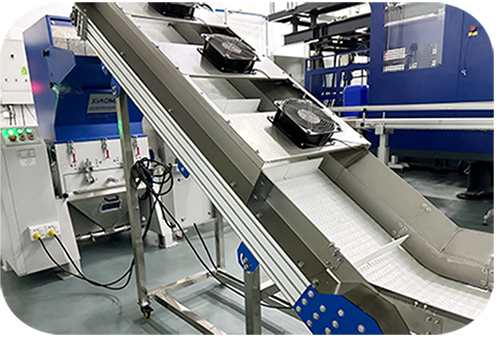

Recycle part:

Good quality crusher and special conveyor with cooling, get the recycle material for reusing.

Inspection part:

Leak part:

Make sure offer NO-LEAK jerry can for final user, we add leak testing process.

Vision inspecter:

Jerrycan surface no impurity, jerrycan color correct, jerrycan neck no surplsu material, jerrycan surface smooth

Package part:

adopt full automatic packing machine, save-labor and clean.

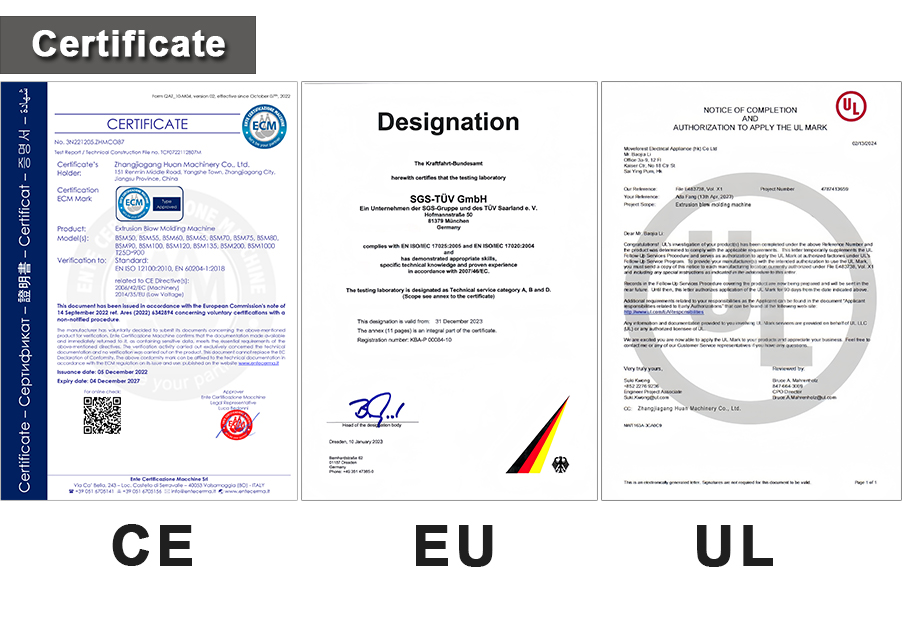

Who are we?

Total solution provider for 25L, 200L and 1000L IBC package project.

What are we?

Coex blow molding machines with Germany technology and focus on zero-labor full automation blowing line.

Why are we?

Clients realize labor-cost saving, high-level output, stable-continuous running, make client’s profit maximum.

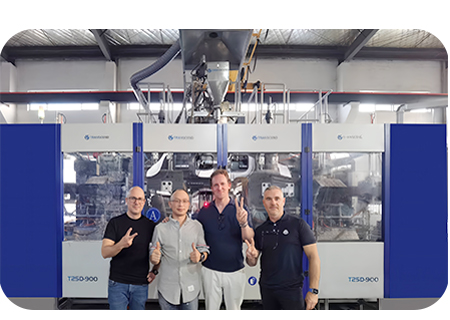

Client from EU country:

After viewing our 25L machine, they give commend:" Can’t distinguish HUAN machine and European machine, considerate & top-level EBM."

Clients from USA:

"Chinese technology is amazing, we have to try this machine."They praised.

Client from EU country:

"We are so excited that we found European-level machine with economic cost", they give comment.

Client from China

"We have to continue to purchase same model machine since our trail is successful". The boss is satisfied the machine performance.