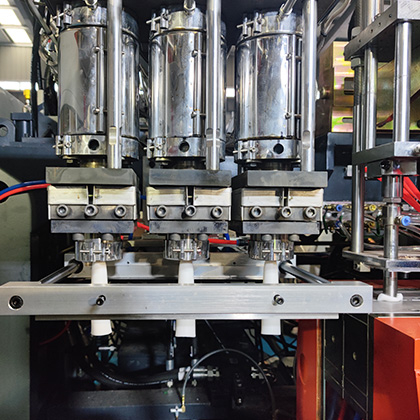

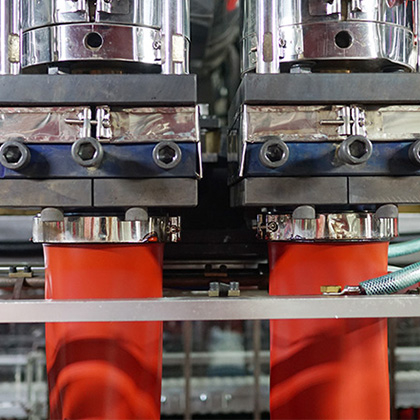

1.Plastic bottles and containers for food, beverages, and household products

2.Automotive parts such as fuel tanks, air ducts, and windshield washer bottles

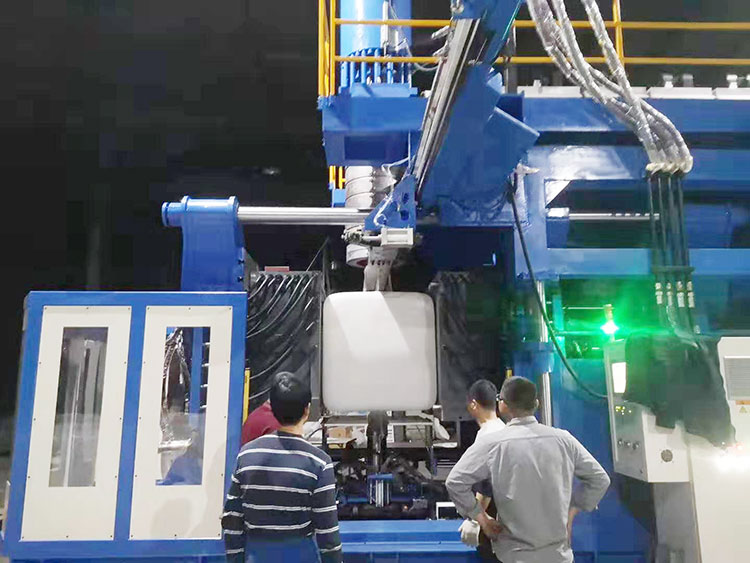

3.Industrial containers such as drums, tanks, and storage containers

4.Toys and sporting goods such as ocean balls, child slide, and sport water bottles

5.Medical products such as eye drop bottle,medical stretcher...

6.Lawn and garden products such as watering pot,two-color prayer kettle...

7.Packaging materials such as 9 feet hdpe pallets

8.Household items such as dish washing liquid bottle, angled neck bottle

9.Personal care products such as shampoo bottle, lotion bottle, cosmetic container