Our extrusion blow molding machine line can be adopted in various HDPE bottle blowing demand such as chemcial liquid bottle, jerry can drum and food bottles such as milk bottle, can, jug, jar, kettle and agriculture bottles, ocean sea ball, children toys, garden jerry can, cosmetic bottle and cans, medicine bottles, table plate, folat block and bridge, pallet, manniquin etc...

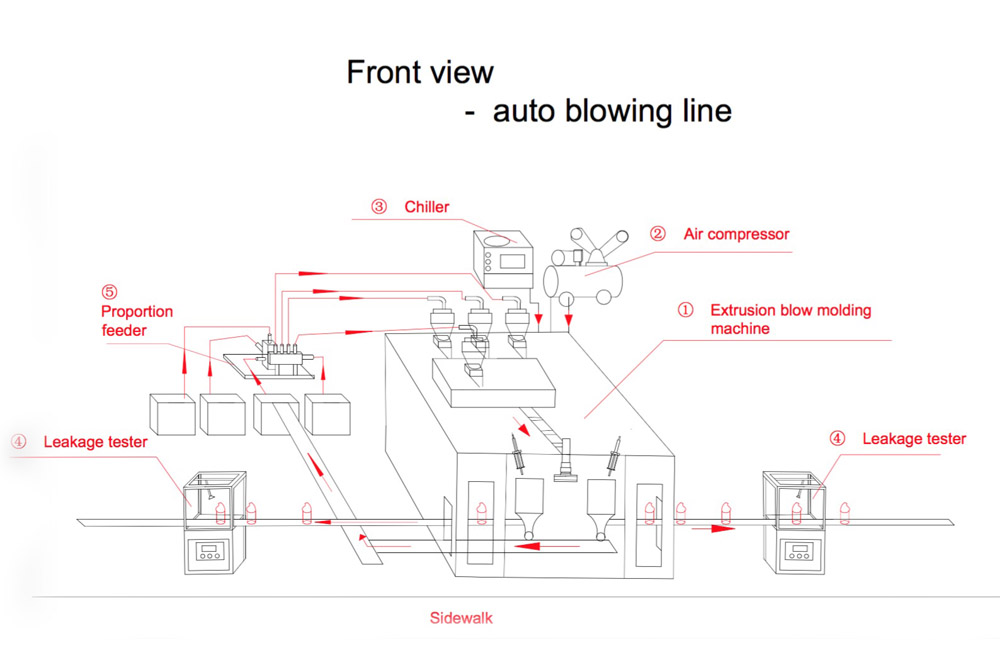

We supply whole production line automaticy type including: extrusion blow molding machine, conveyor, leak tester, chiller, mixer, auto-loader, granulator, compressor, auto bagging machine, etc...

We have suitable machine model if we know your bottle size weight and ouputput demand idea.

| MACHINE MODEL | HJS80D |

| SPECIFICATIONS | Material | PE PP PVC PA... |

| Max container capacity | 10L |

| Number of die | 1,2,3,4,6 |

| Machine Dimension(LxWxH) | 4x2.3x2.5m |

| Total weight | 8.2ton |

| CLAMPING UNIT | Clamping force | 150kN |

| Platen openning stokes | 220-620mm |

| Carriage stroke | 540mm |

| Max mould size(WxH) | 520x460mm |

| EXTRUSION UNIT | Screw diameter | 80mm |

| Screw L/D ratio | 24 L/D |

| (HDPE) Plasticizing capacity | 108kg/h |

| Screw heating zone | 4 zone |

| Screw heating power | 15.6kw |

| Screw fan power | 0.14kw |

| Extrusion motor power | 30kw |

| DIE HEAD | Die head heating zone | 3 zone |

| Power of die heating | 13.5kw |

| ENERGY CONSUMPTION | Total power of machine | 74.98kw |

| Power of oil pump motor | 11kw |

| Air pressure | 0.6-0.8 Mpa |

| Average energy consumption | 35kw |

| Consumption compression air | 1.5m3/min |

| Consumption cooling water | 40L/min |