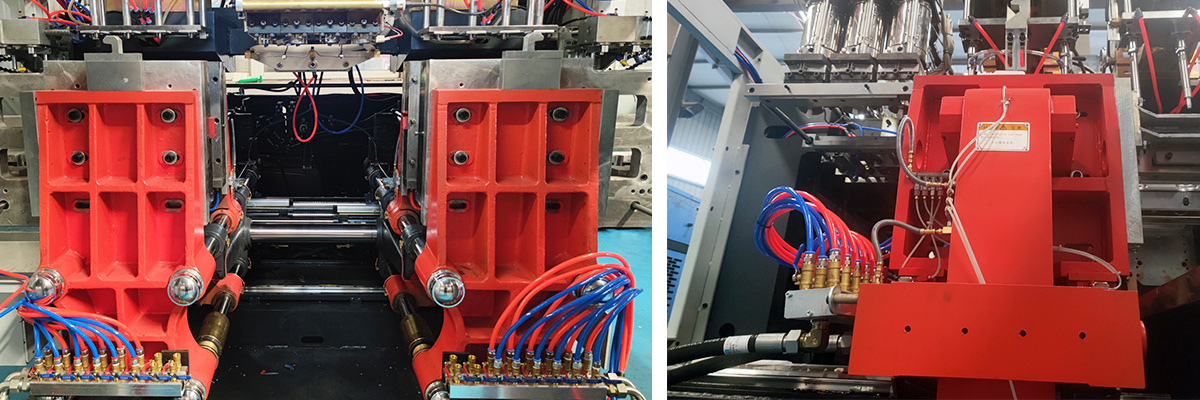

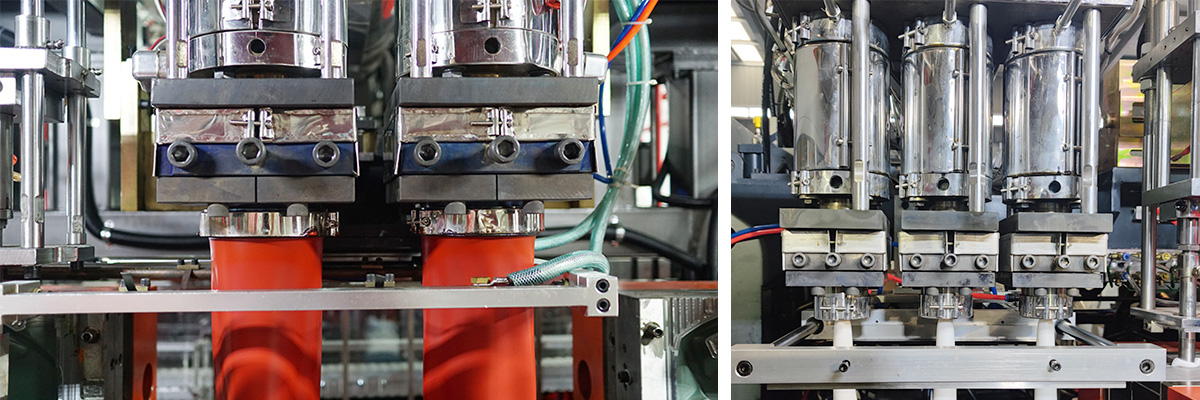

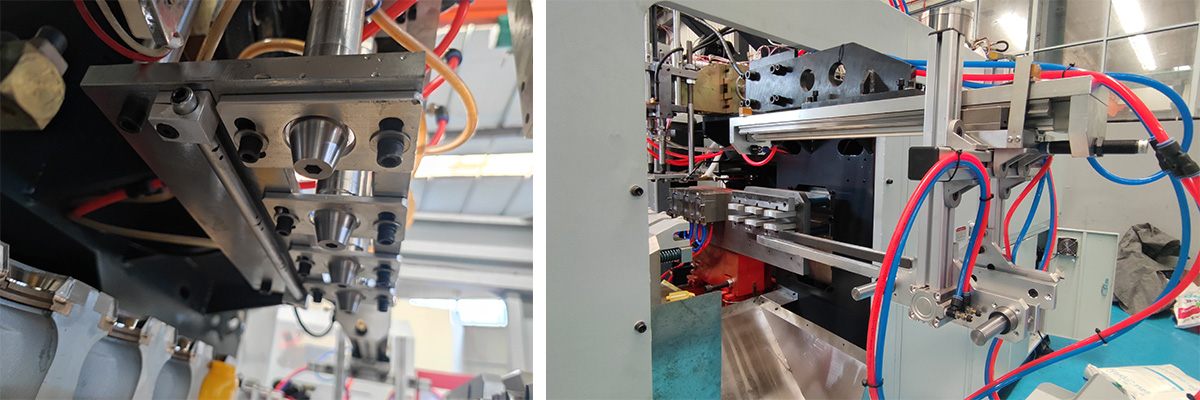

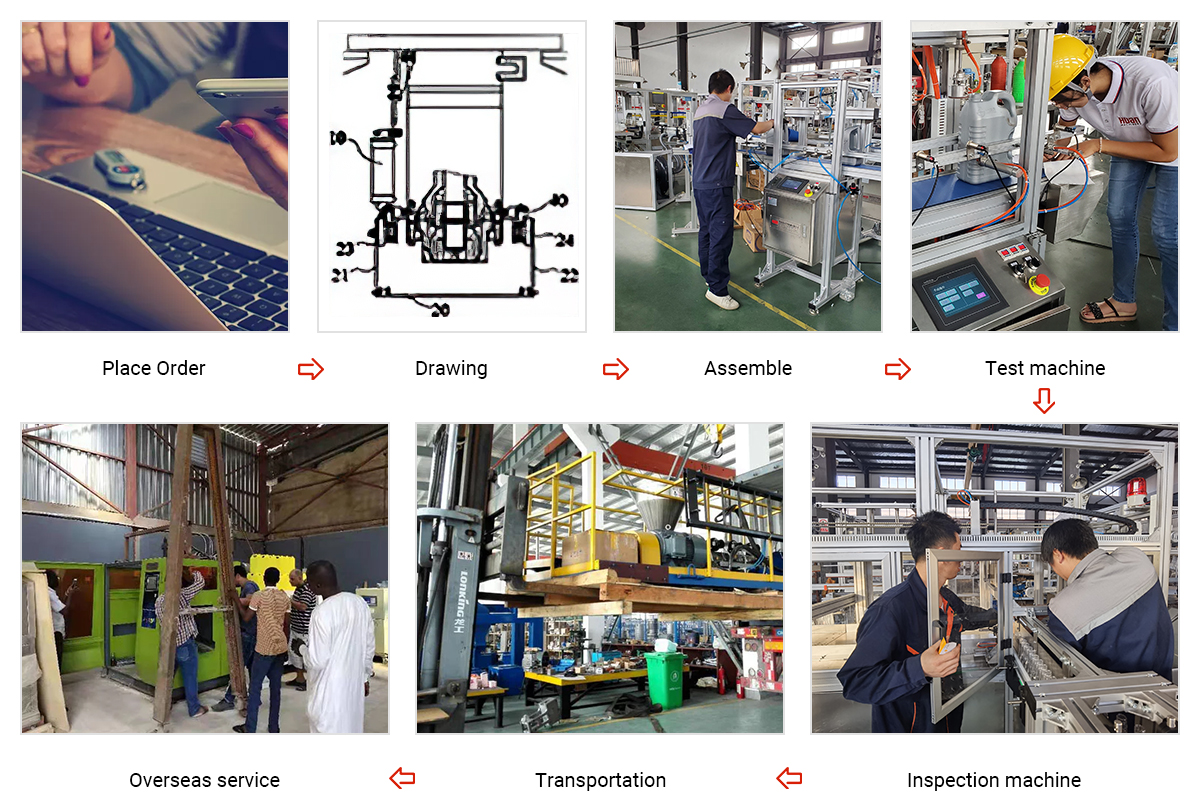

We have more than 15 years experience in multilayers extrusion blow molding machines.The machine can use recycled plastic material for producing the plastic bottles.Our extrusion blow molding machine can produce hollow bottles from 5ml to 5000L with material HDPE, LDPE, PP, PVC, EVA, EVOH, PA, PVC, ABS such as bottle ,jerry can, canister, container, can, jar, jug, kettle, drum, barrel and other abnormal shape produce such as ocean sea ball, children toys, seat, auto parts, table plate, mannequin, float block, float bridge and others.