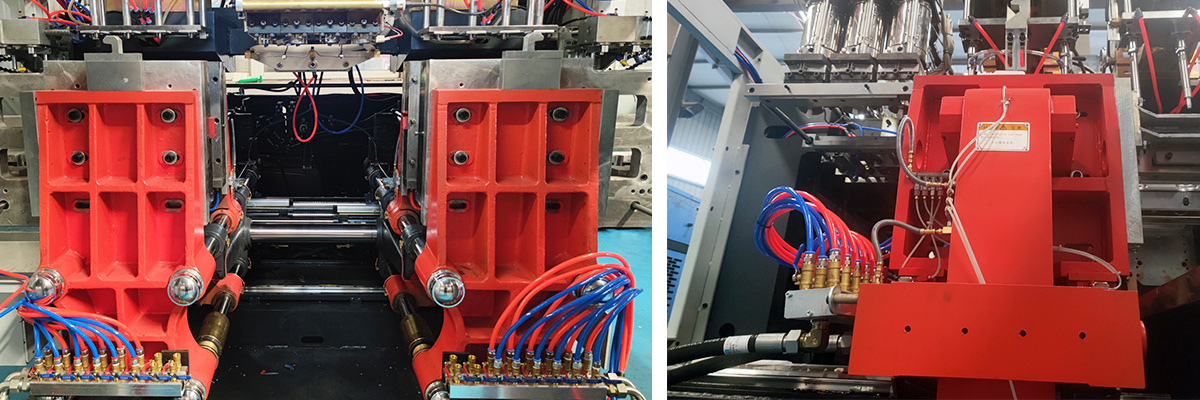

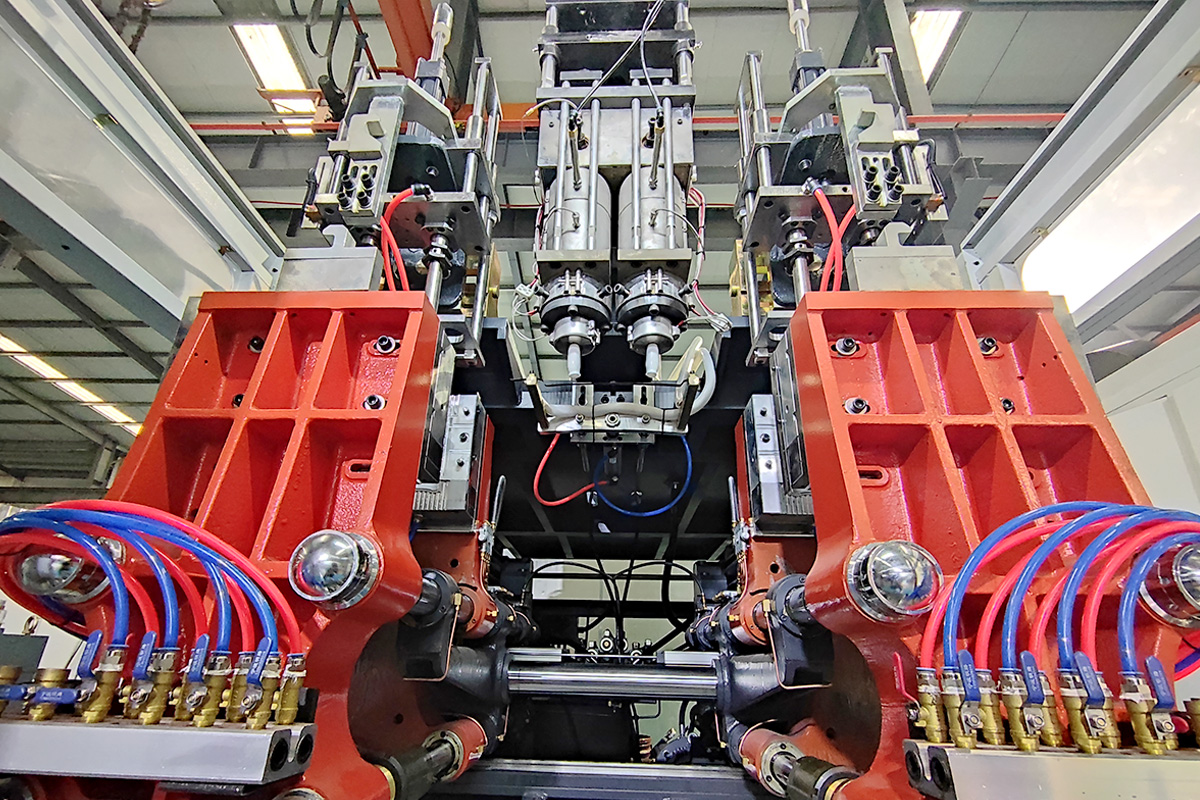

The extrusion blow molding machine is standard type machine with double station tie bar structure, The clamping structure is three or four tie bars direct locking structure with automatic lubrication system. The structure is simple and stable and it is convenient for plastics waste collection.

The extrusion blow molding machine advantage:

Linear carriage with smooth, accurate movement and bobbing head.

Full proportional control of the carriage, clamp and blowpin are available with our extrusion blow molding machines.

Choice of top quality controllers with user friendly large color screens

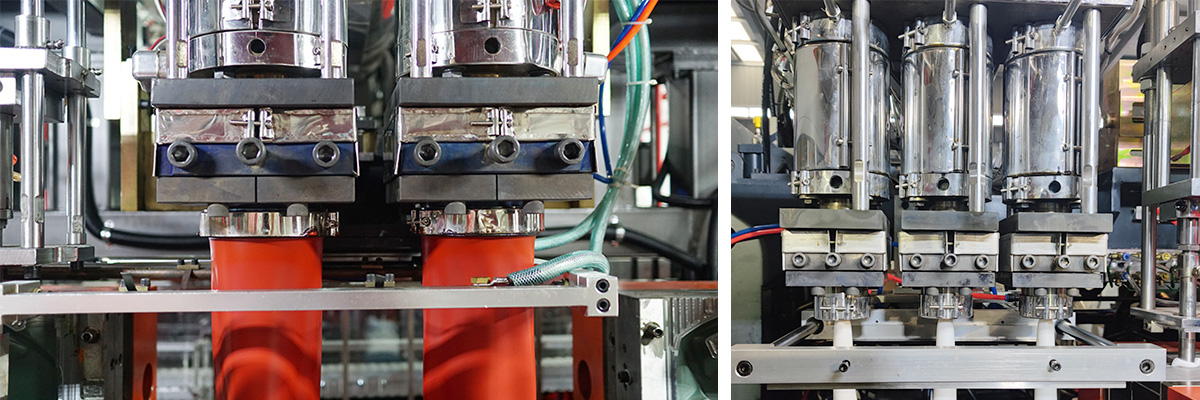

Many special features are standard such as adjustable angled blow pins and extruder platform, 100 point parison controller.

Automatic scrap/deflash removal available

Availability of components in North America – no costly downtime

Easily the best extrusion blow molding machine for ROI: outstanding price-quality ratio and investment return

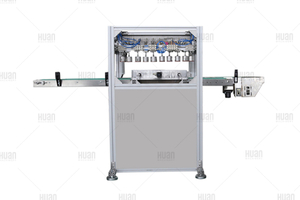

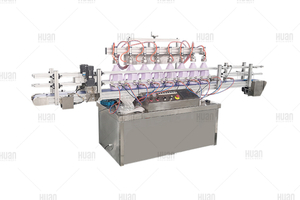

Our extrusion blow molding machines can come complete with scrap conveyors, bottle discharge conveyors, material loading systems, grinders, Etc.

We are specialized in the design and manufacture of bottles, jars, tight head containers & large water containers in a range of different shapes, sizes and materials.

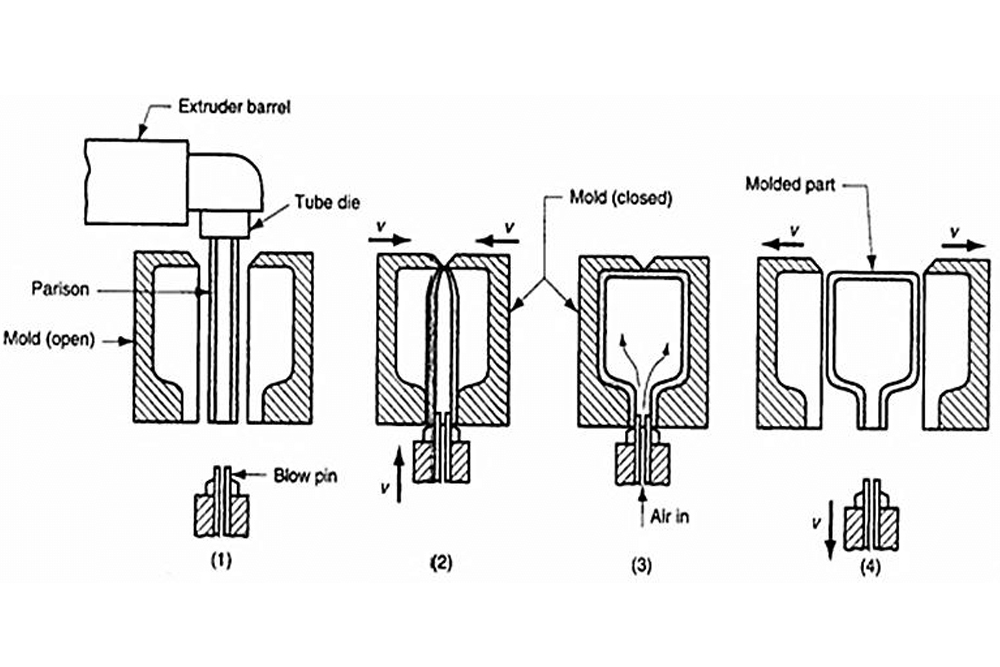

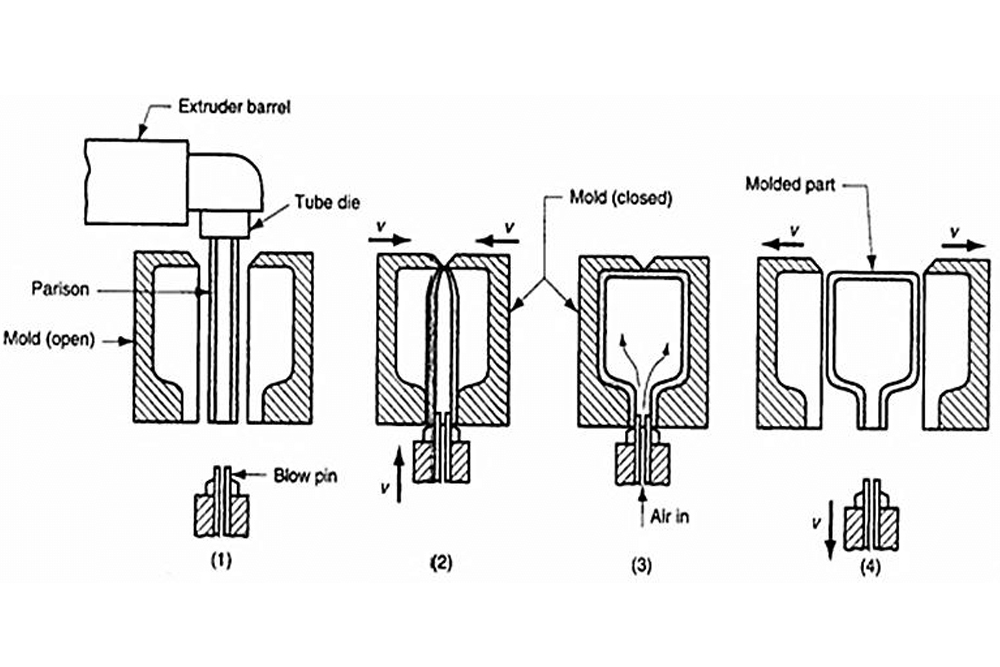

Extrusion blow molding is a process for directly manufacturing hollow plastic bottles/containers by using the machines extruder, die head, clamp unit (press) and mold. The bottles/containers manufactured by the extrusion blow molding process have the following features:

High impact resistance

Flexible part design

Easily controlled wall thickness

Environmental resistance

Durability at light weights

Ideal for decoration (screen print and label)

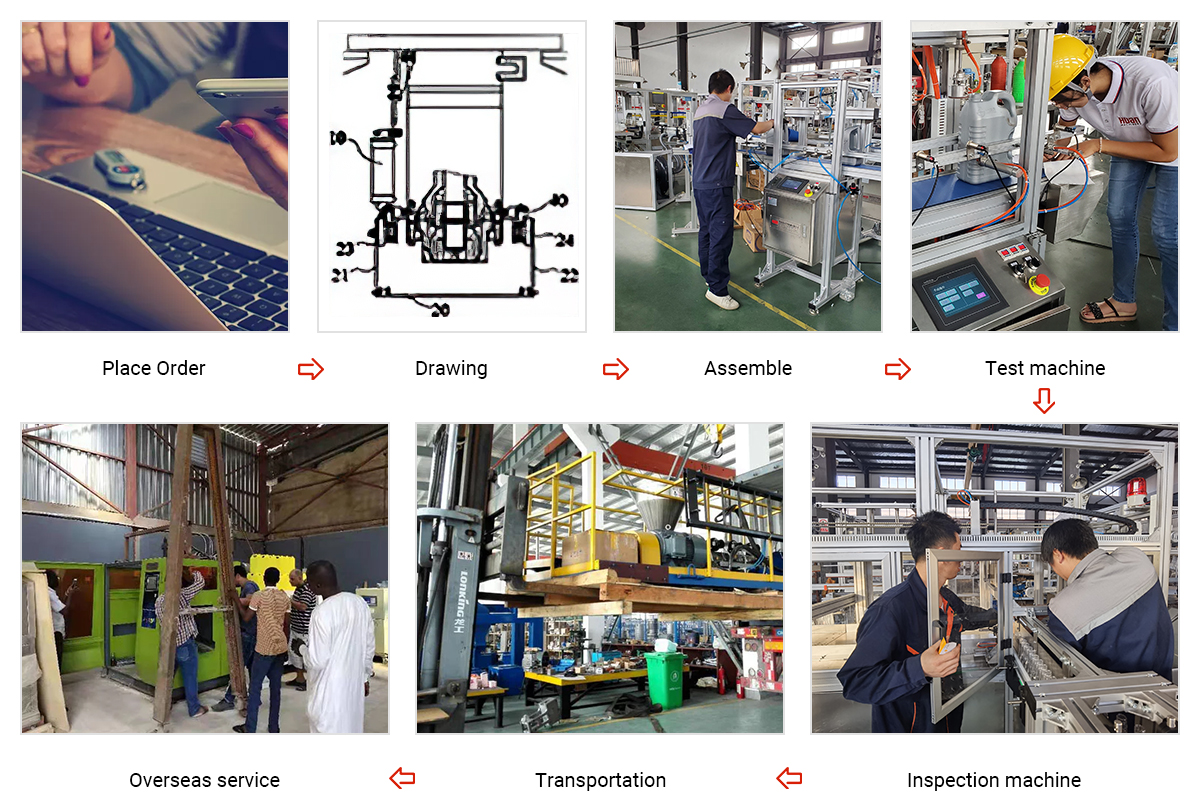

Process: Extrusion Blow Molding Machinery

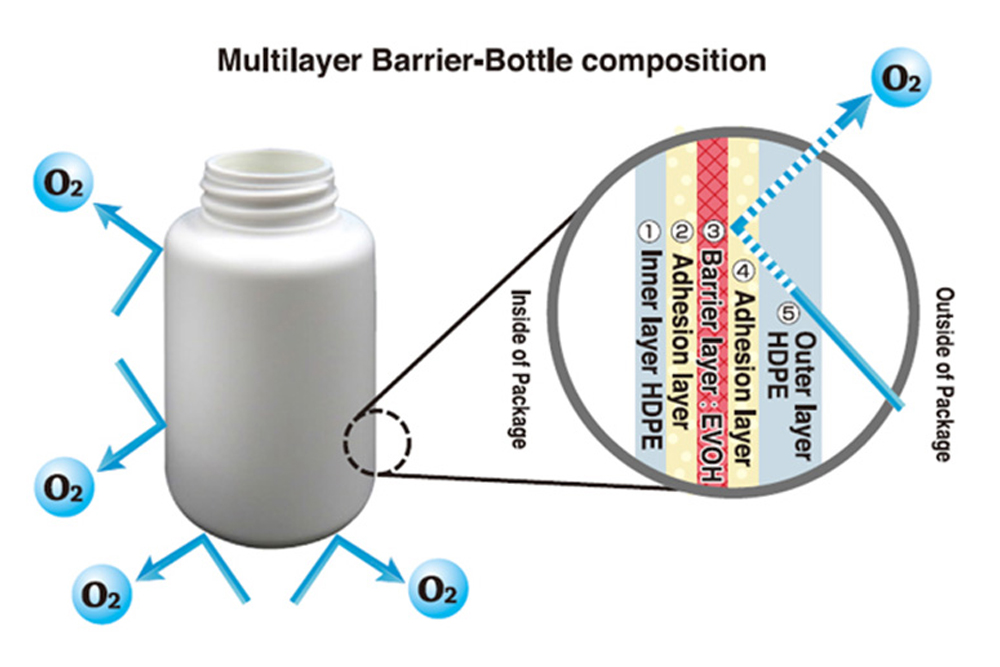

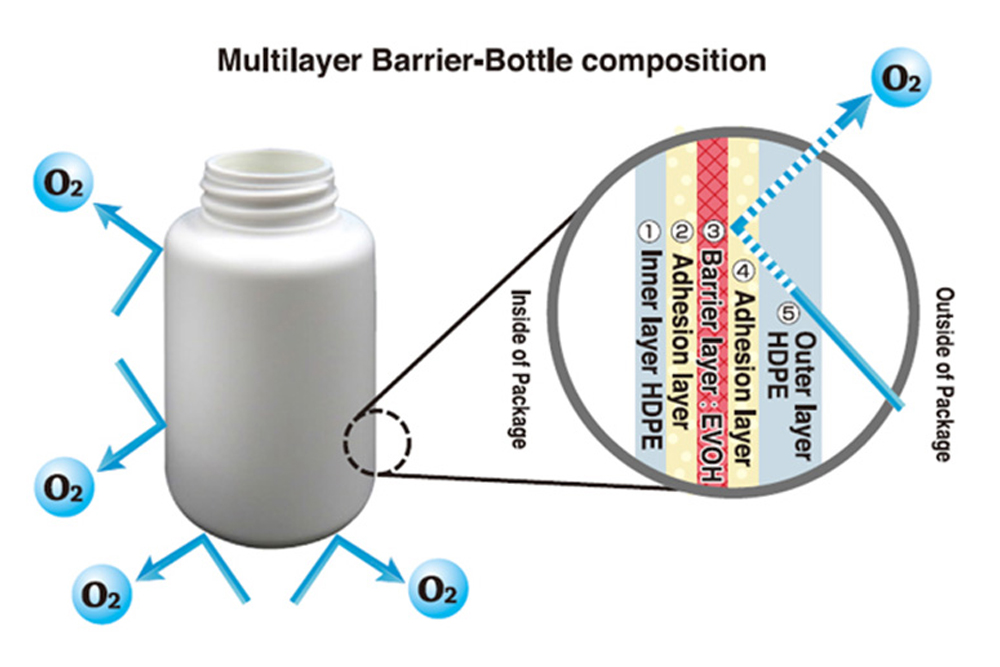

The whole machine adopts computer control, simple operation, reliable work, high degree of automation, good interchangeability of components,realize one machine multi-purpose. It can choose single and double mode-shifting models to meet different output requirements. It can be equipped with single head, double head, four head, multi-layer head, double transparent line head and servo wall thickness control head to meet the requirements of different products.The extrusion blow molding machine can produce multilayers hollow plastic products also,1 layer to 6 layer can be optional.