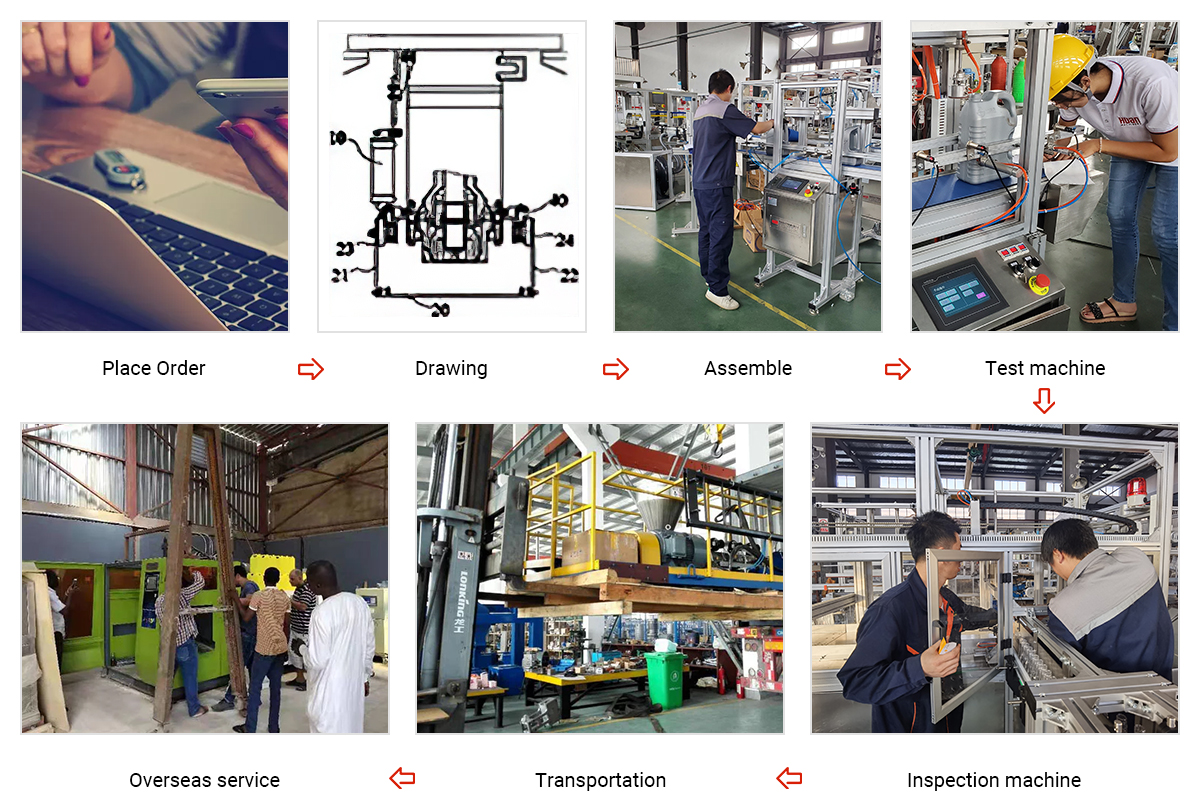

HJS80FD-1T-3P Extrusion blow molding machine for 10L stackable jerry can

Due to the non-degradability of plastics, our environment has been seriously polluted. Therefore, we are also committed to multi-layer extrusion blow molding machines to increase the utilization rate of recycled plastics and reduce plastic waste. Multi-layer blow molding machine can increase the recycled material layer when producing plastic products, we have 2 layers,3 layers,4 layers,5 layers, 6 layers extrusion blow molding machines,which are widely used in the chemical industry, daily chemical industry, food industry, agriculture and other fields.

Machine Feature

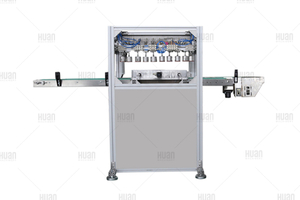

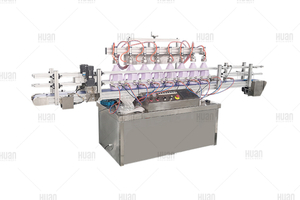

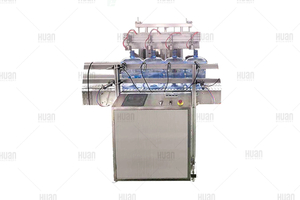

Double station, single-head, 3 layer

• 3 layer screw 70mm/80mm/70mm

• Single head

• with view line system 25mm

• With B&R parison controller

• With hydraulic moving changeable filter for Recycled material layer

• With special fans for the deflashing part cooling

• With servo liner robot arm

• With servo hydraulic system

• With electrical head up

• Conveyor system for deflashing parts, straight and climbing parts.

• Conveyor system for finished product.

· With standard deflashing system

MP80FD-1T-3P

70/80/70/25mm three layer specifications: | Parameter |

Material | PE PP |

Max.container capacity | 10L |

Number of die head | 1 |

Machine dimension (L×W×H) | 3.3*5.5*2.8M |

Total weight | 12T |

Clamping unit : |

|

Clamping force | 150KN |

Platen opening strokes | 240-620mm |

Carriage stroke | 600mm |

Max. Mould size (W×H ) | 550*430mm |

Extrusion unit : | Screw 1. | Screw II. | Screw III. | Screw IV. |

Screw diameter | 70mm | 80mm | 70mm | 25mm |

Screw L/D ratio | 24L/D | 24 L/D | 24L/D | 22L/D |

Plasticizing capacity (HDPE) | 70kg/h | 108kg/h | 70kg/h | 15kg/h |

Screw heating zone | 3 Zone | 4 Zone | 3 Zone | 2 Zone |

Screw heating power | 14.1kw | 15.6kw | 14.1kw | 2kw |

Fan power | 0.14kw | 0.14 Kw | 0.14kw | / |

Extruder driving power | 18.5kw | 30kw | 18.5kw | 1.5kw |

Die head unit : |

|

Die head heating zone | 10 zone |

Power of die heating | 14.3kw |

Energy-consumption unit : |

|

Total power of machine | 158kw |

Power of the electric motor | 29kw |

Air pressure | 0.6-0.8Mpa |

Average energy consumption | 110kw |

Consumption compression air | 1.2m³/min |

Consumption cooling water | 80L/min |

|

Welcome to send us inquiry if you are interested.