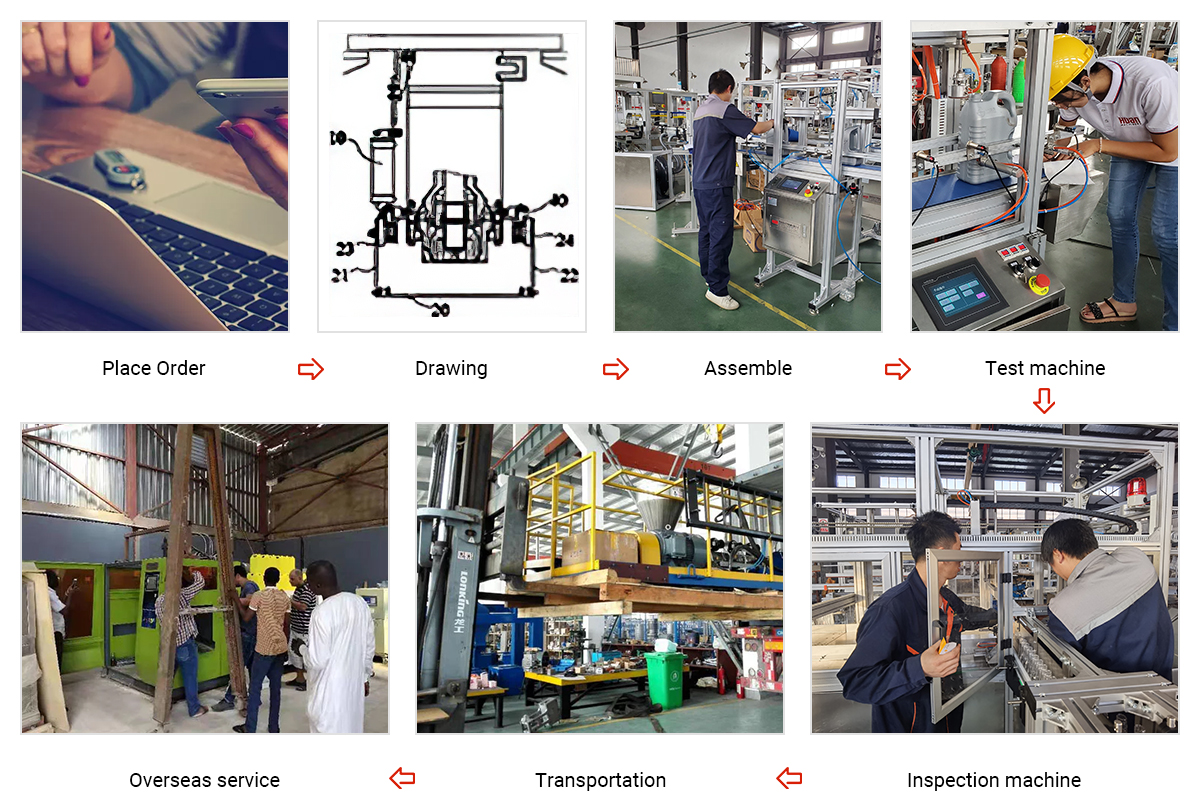

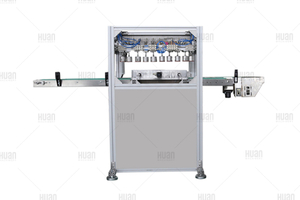

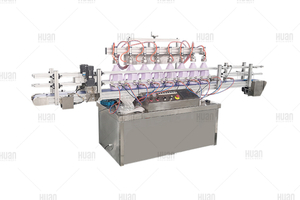

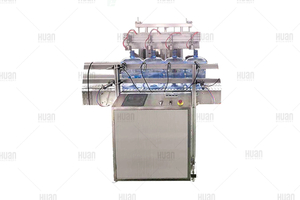

China machine high quality PEHD bottle making PEAD plastic container extrusion blow molding machinery

Due to the non-degradability of plastics, our environment has been seriously polluted. Therefore, we are also committed to multi-layer extrusion blow molding machines to increase the utilization rate of recycled plastics and reduce plastic waste. Multi-layer blow molding machine can increase the recycled material layer when producing plastic products, we have 2 layers,3 layers,4 layers,5 layers, 6 layers extrusion blow molding machines,which are widely used in the chemical industry, daily chemical industry, food industry, agriculture and other fields.

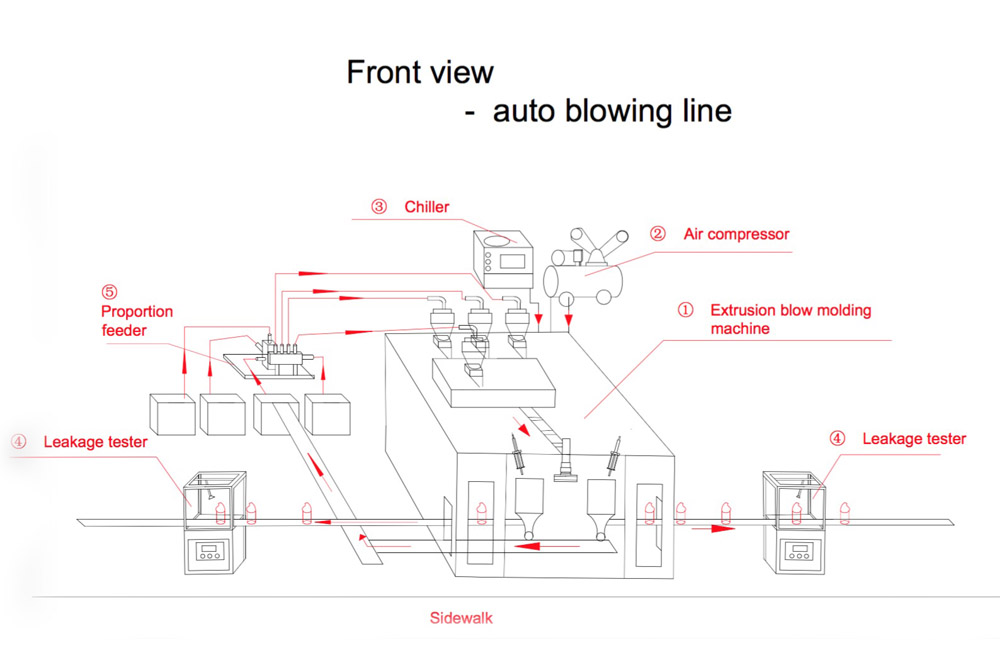

We supply full production line including:

auto loader

mixer

chiller

compressor

granulator

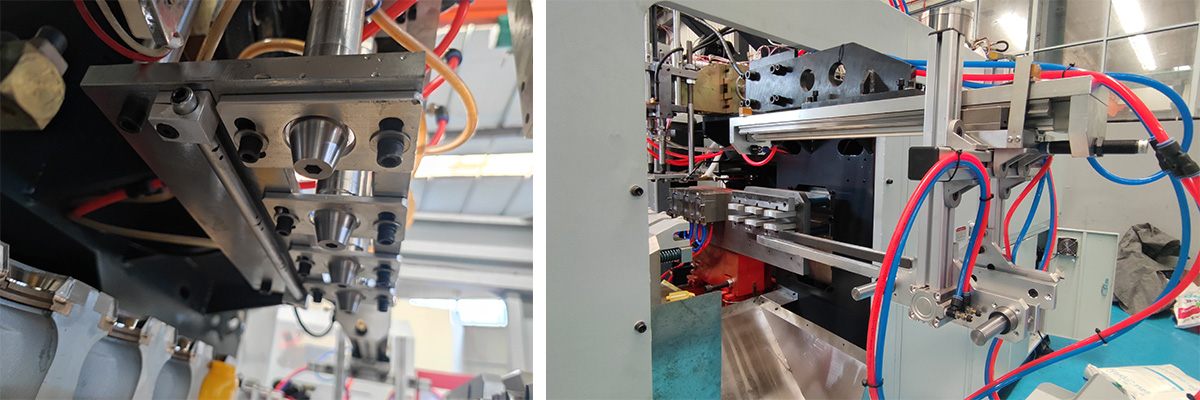

neck cut device

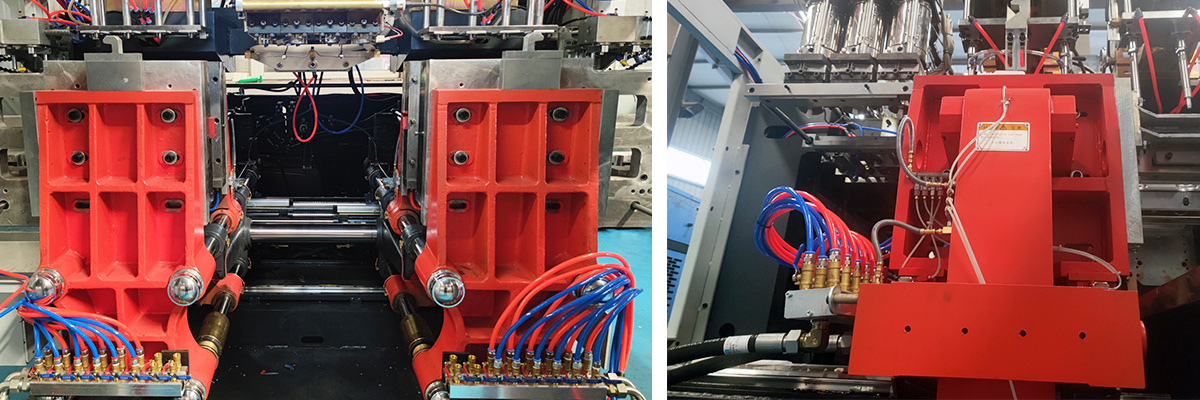

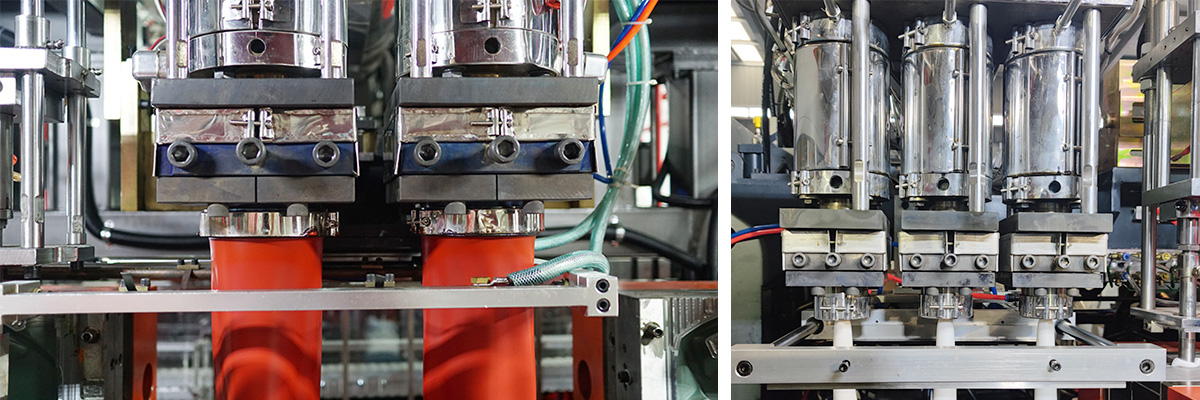

mold

others

welcome to send us inquiry if you are interested.

Extrusion blow molding machine parts brand

| Name | Supplier |

| Hydraulic Servo Motor | PHASE/ Italy |

| Oil Pump | SUMITOMO / JAPAN |

| Hydraulic Valve | YUKEN/ JAPAN |

| Servo Valve | ATOS/ Italy |

| Parison control system | MOOG/JAPAN |

Extrusion blow molding machine parameter

| 基本规格 SPECIFICATIONS |

|

| 适用原料Material | PE PP PVC PA... |

| 制品容积container capacity | 10L |

| 机头数 Number of die | 1,2,3,4,6 |

| 机器外形尺寸 Machine Dimension(LxWxH) | 4x2.3x2.5m |

| 机器重量Total weight | 8.2ton |

| 锁模系统 CLAMPING UNIT |

|

| 锁模力 Clamping force | 150kN |

| 模板间距 Platen openning stokes | 220-620mm |

| 移模行程 Carriage stroke | 540mm |

| 模具尺寸 mould size(WxH) | 520x460mm |

| 挤出系统 EXTRUSION UNIT |

|

| 螺杆直径 Screw diameter | 80mm |

| 螺杆长径比Screw L/D ratio | 24 L/D |

| 塑化能力 (HDPE) Plasticizing capacity | 108kg/h |

| 螺杆加热段数Screw heating zone | 4 zone |

| 螺杆加热功率Screw heating power | 15.6kw |

| 螺杆风机功率Screw fan power | 0.14kw |

| 挤出电机功率 Extrusion motor power | 30kw |

| 机头 DIE HEAD |

|

| 机头加热段数Die head heating zone | 3 zone |

| 机头加热功率Power of die heating | 13.5kw |

| 能耗 ENERGY CONSUMPTION |

|

| 总装机功率 Total power of machine | 74.98kw |

| 油泵电机功率 Power of oil pump motor | llkw |

| 气源压力Air pressure | 0.6-0.8 Mpa |

| 平均能耗 Average energy consumption | 35kw |

| 压缩空气用量 Consumption compression air | 1.5m3/min |

| 冷却水用量 Consumption cooling water | 40L/min |