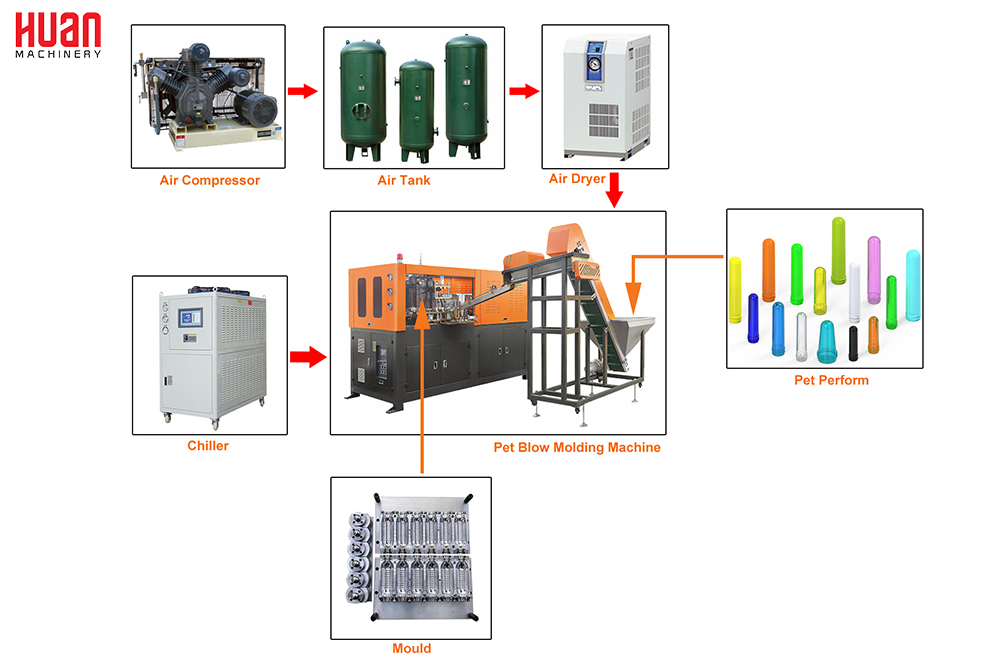

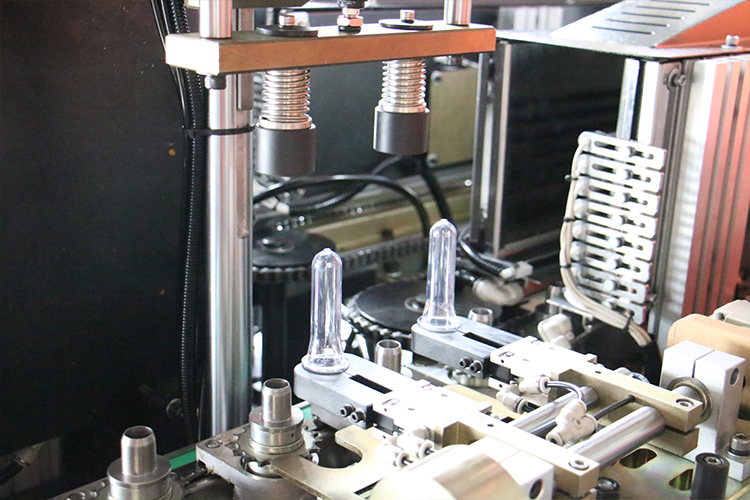

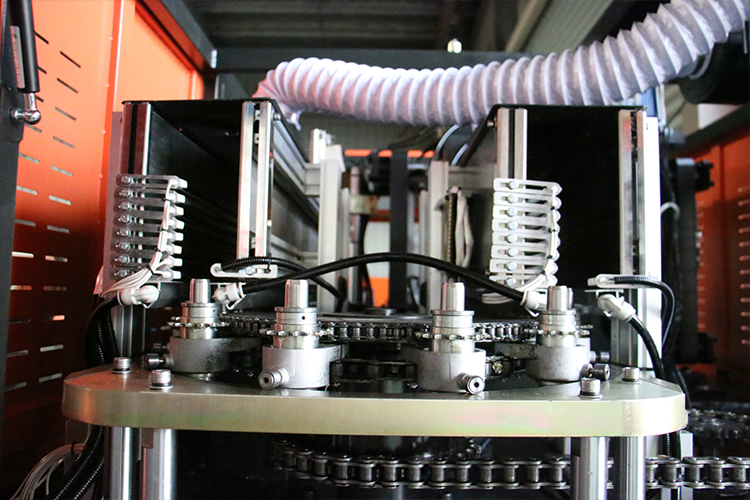

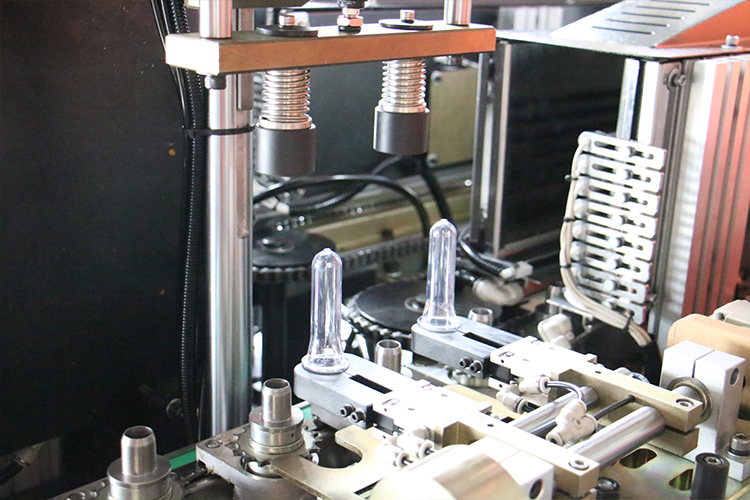

The machine is a fully automatic bottle blowing machine developed for blowing PET bottles with a capacity of less than 2L. The fully automated preforming and epiforming mechanism improves work efficiency and transportation is accurate. In addition, the raw materials are completely free from pollution and loss during transportation. The feeding process is self-transported, with a unique clamping system. The whole clamping is driven by a servo motor, a mechanical linkage type.

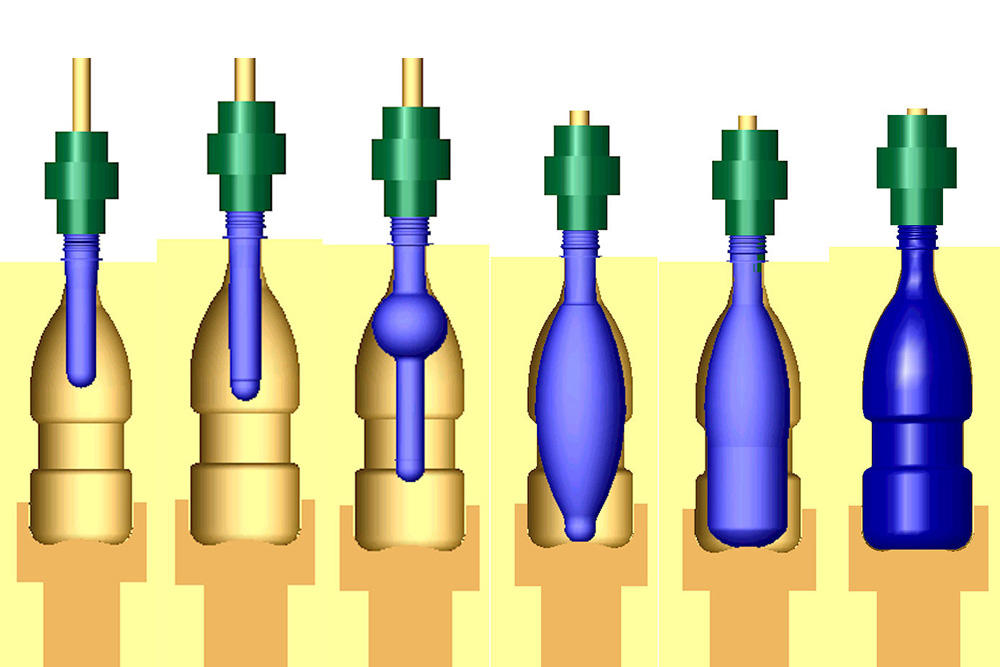

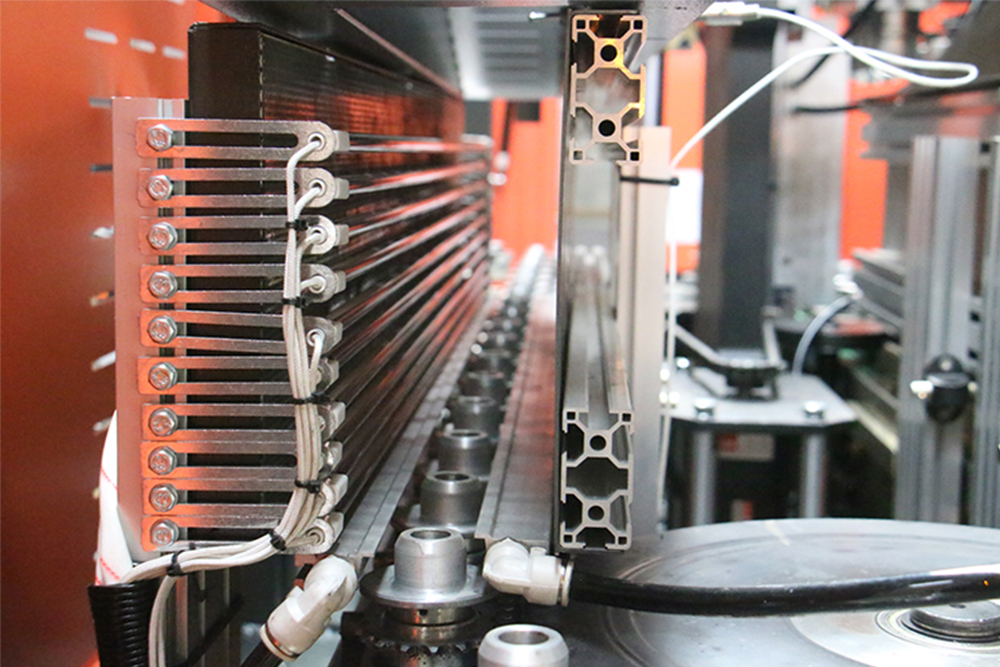

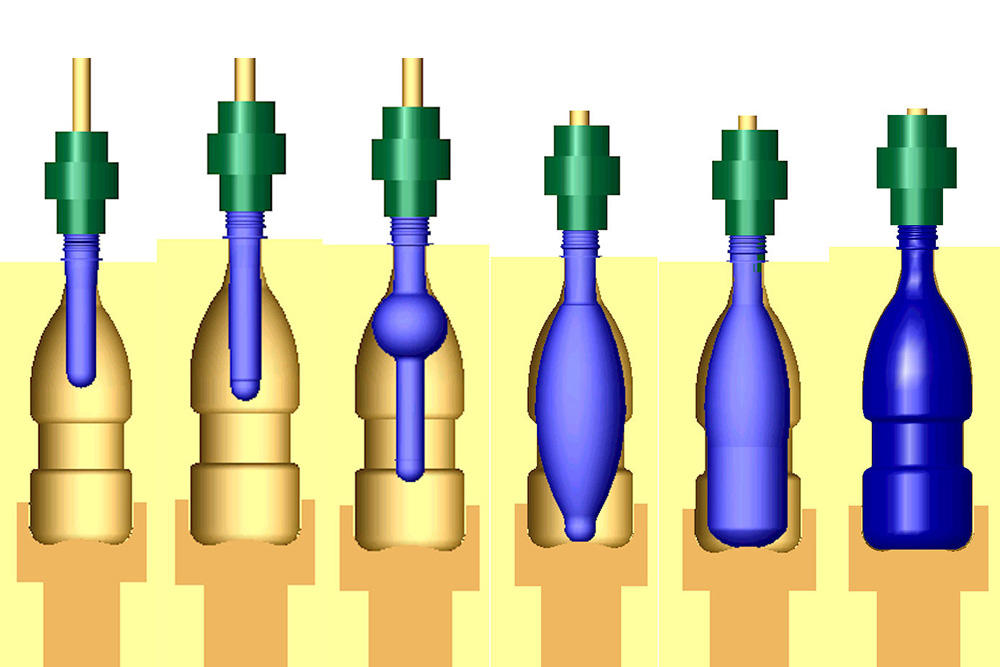

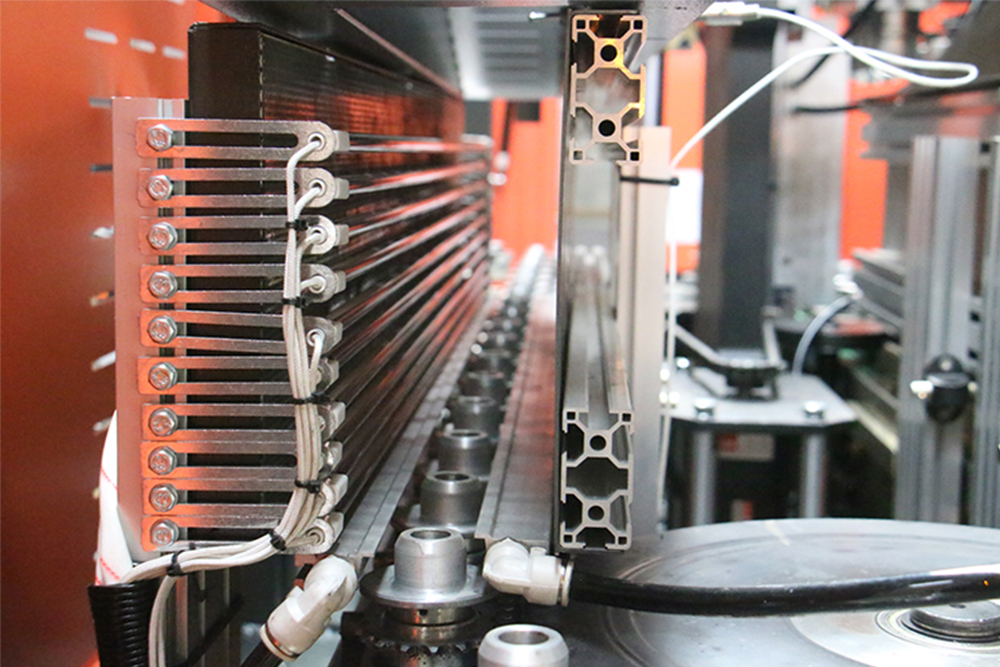

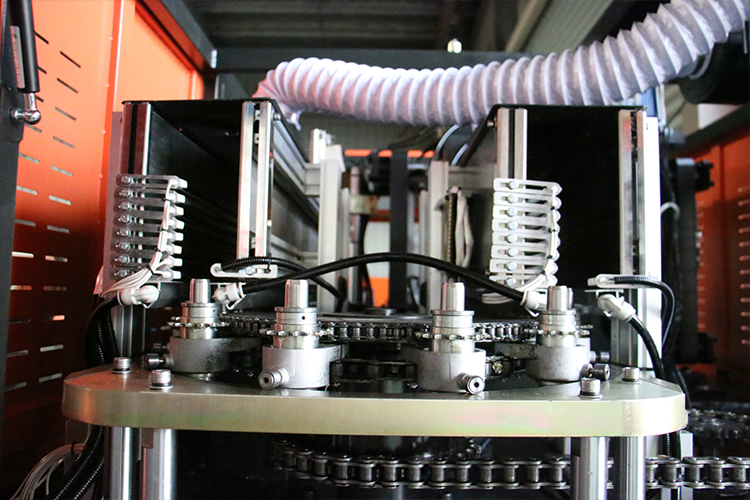

In PET blow molding, Reheat Stretch Blow Machines are the second part of the process of bottle manufacturing. They load completely cooled down preforms onto rotating mandrels, heat them up to blowing temperature through an oven section, allow a short period for equalization and then stretch and blow them into bottles.

At Pet All Manufacturing, we offer three distinct types of plastic blow molding machines:

Linear shuttle machines: 1 up to 6 cavities - This PET blow molding machine is available in both small and medium output at a low cost.

Small and medium output at low cost

Linear machines with continuous preform motion: 1 to 12 cavities

Even heat distribution and easy operation

Rotary machines: 10 and 14 cavities - For this PET blow molding machine, you benefit from high output at an even lower cost.

High output at a lower cost

PET bottle blowing machine feature:

1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs.

4. manual and automatic methods of operation, human-machine interface control, simple operation.

5. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

6. less than 0.2% scrap rate for finished bottle .

PET preform for plastic bottles

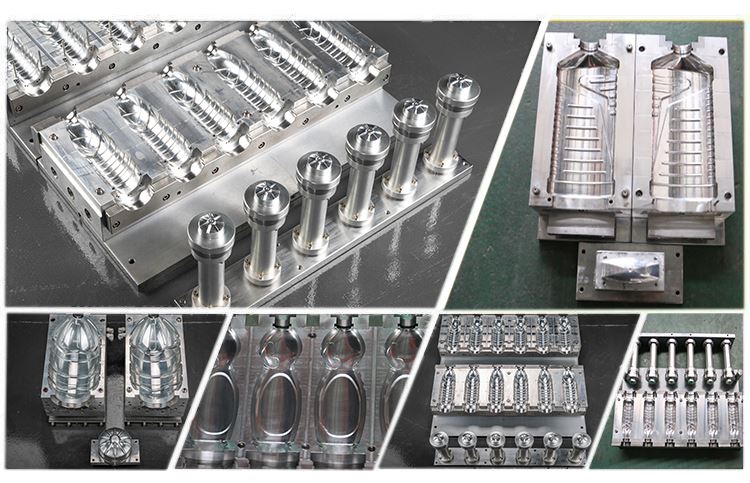

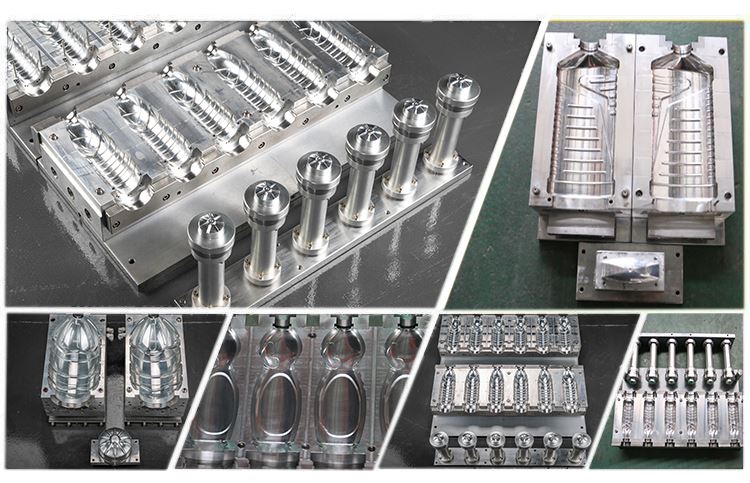

Customized mould for pet bottles

Packing and shipping for pet bottle blowing machine

Huan Machinery Sales Manager Team and Engineer Team.

1 .Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

2. The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.