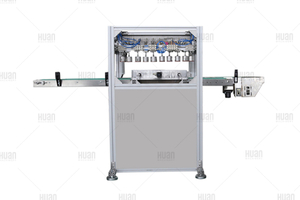

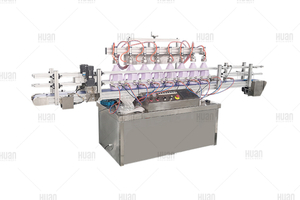

Products Character

This is an automatic capping machine equipped with an existing conveyor.At a rate of up to 30 caps per minute,it tightens different sizes of bottle caps,and we can customize the capping mold according to your needs. We designed it to provide our customers with self-contained, and easy to adjust automatic bottle capping machine.

What is Capping Machine and Why it is required?

What is Capping Machine and Why it is required?

Capping Machines, tighteners are used for sealing the filled bottles, containers, Vials, jars and related . Caps are devices that are used to close off a container. Caps prevent product leakage, product contamination, to extend a product’s shelf life, and prevent tampering. The different type of products that are packaged and the containers that they fill are different in nature so there are large number of processes, techniques and machines are used for sealing. There is an important role of sealing and capping in optimal product packaging. Its protect the product by varieties of caps and seals if capping is done by correct method that only ensure product safety, quality and efficiency.

Technical Parameters

| Cap type | Aluminum cap,plastic cap |

| Capacity | 1500bph |

| Bottle diameter | Φ 50-100mm (bottle can be round or flat) |

| Bottle mouth diameter | 18-34mm |

| Height of bottle | 100-350mm |

| Power | 0.75kw |

| Machine weight | 400KG |

| Machine size | 1000*750*1900mm |

|  |

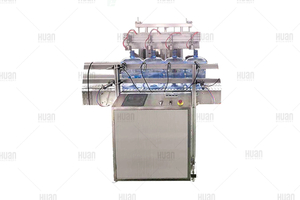

Capping screw parts

| Plastic bottle cap screw |

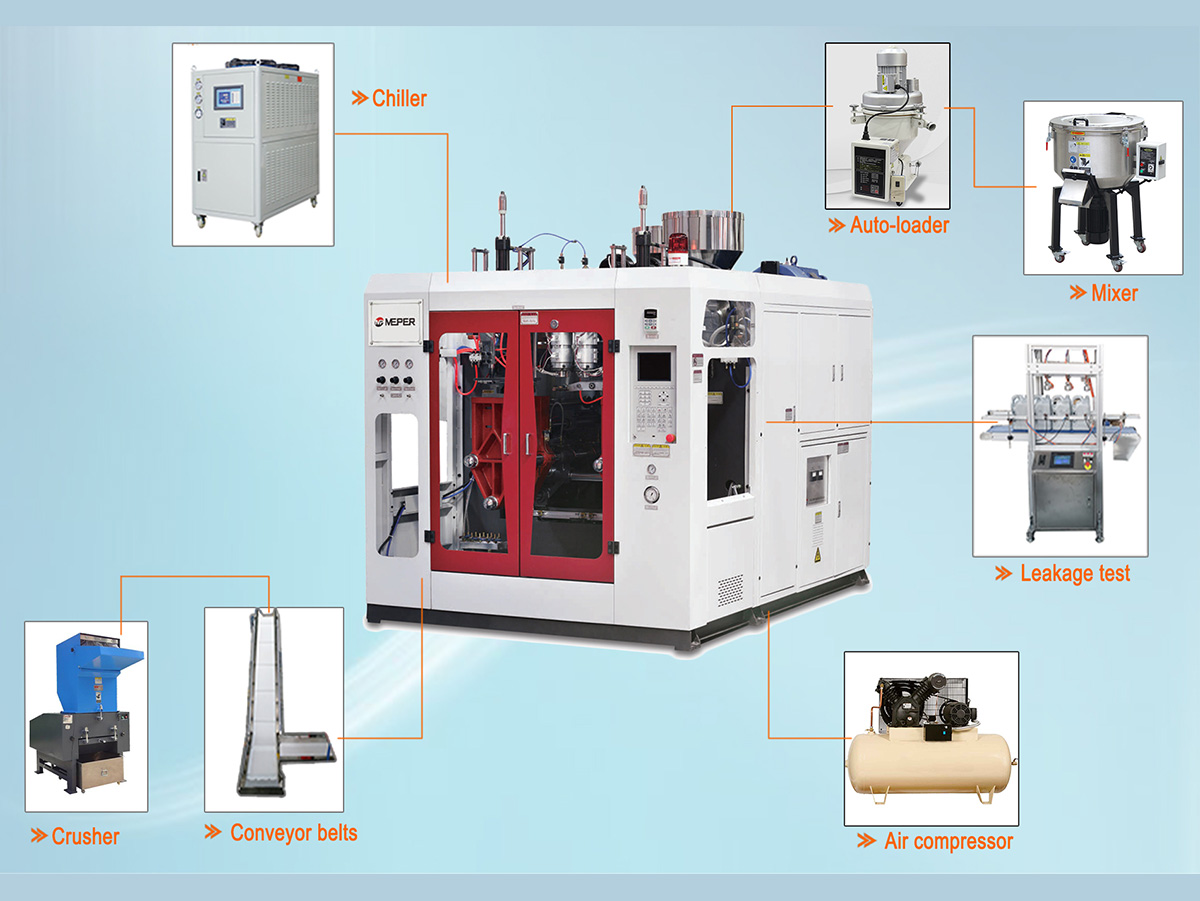

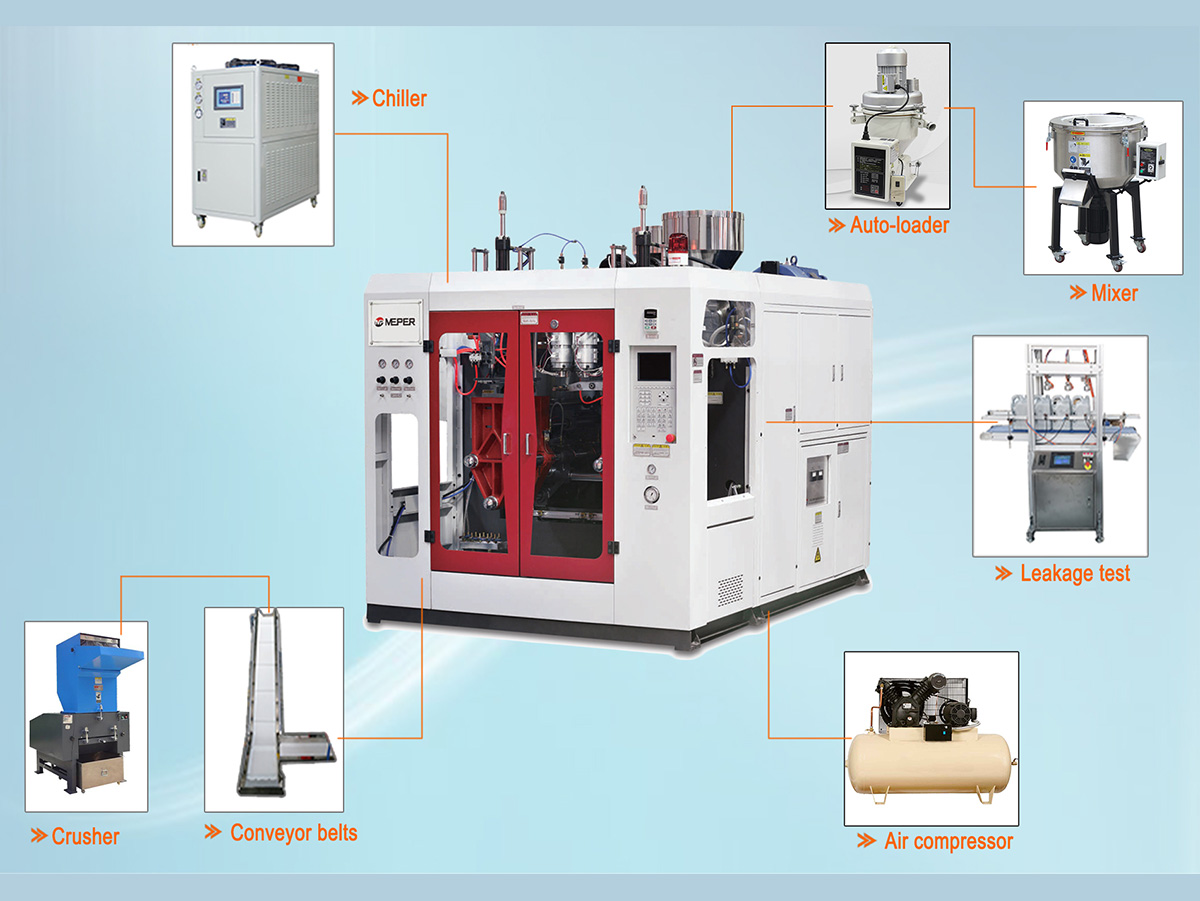

Auxiliary equipment is equipped to realize the automation of blow molding machine production.