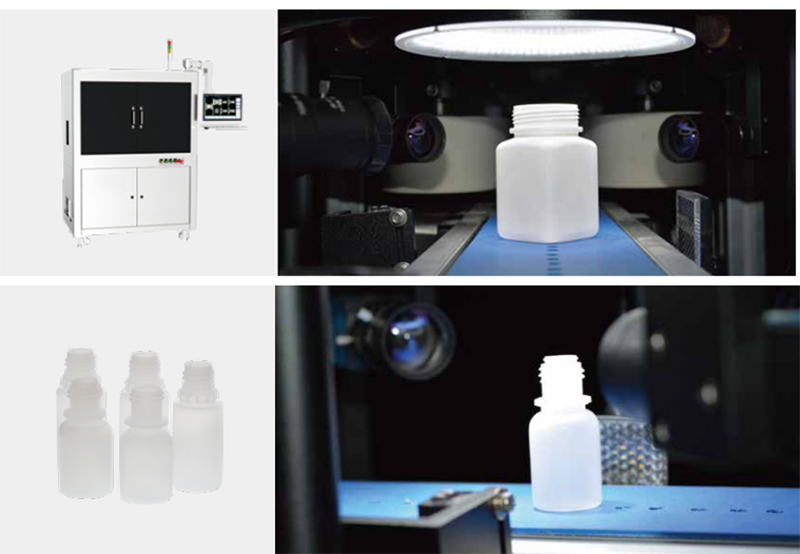

Suitable for transparent or non-transparent bottles such as dairy products bottles, daily chemical bottles, mineral water beverage bottles, cosmetic bottles, etc.

It can be directly connected to various blow molding machines, or used with a reasonable bottle machine.

It can be connected with the back-end auxiliary equipment such as leak detector, packing machine, packing machine, etc.

The equipment operation is easy Io understand, and equipped with remote testing& comis sioning function.

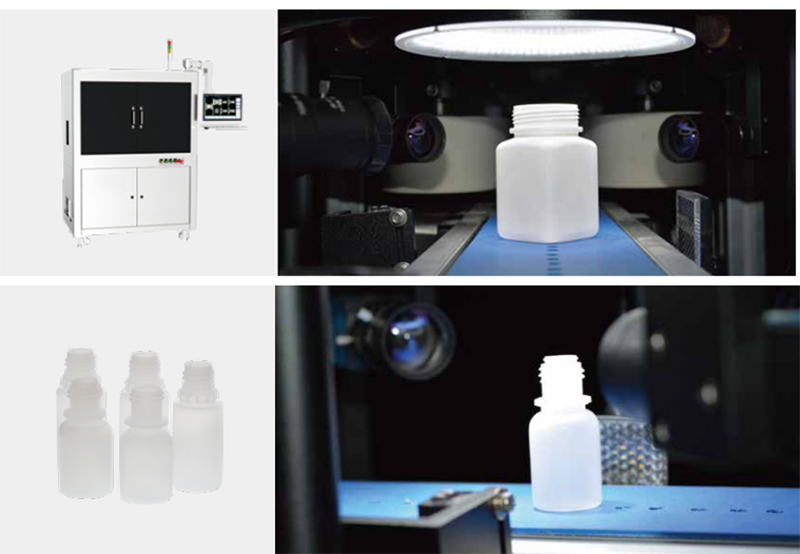

An overall inspection of bottle mouth,bottle body and bottle bottom.

Detection of defects such as flash, lack of material, black spots, dirt, uneven thickness, deformation, etc.

The high-speed bottle inspection machine can meet the simultaneous connection requirements of multiple equipment.up to 36,000 bottles per hour.

Al deep learning algorithms are good at handling various complex inspection projects.

Special light source design with the system for the secondary camera to simultaneously detect inside and outside the product.

Equipped with 6-19 cameras according to different needs.

Manual adjustment. Semi-automatic adjustment, and full-automatic adjustment are available in three types.

Production data recording, analysis, statistics, automatic and intelligent quality inspection