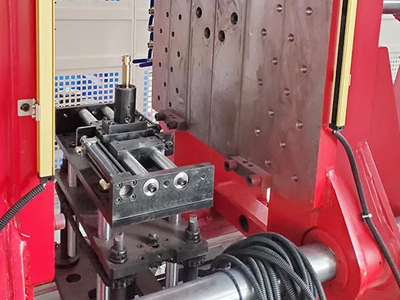

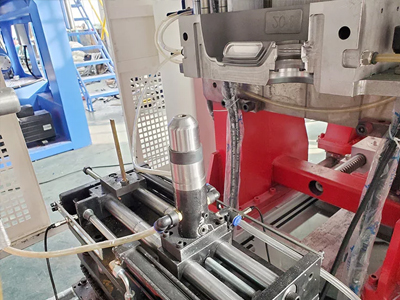

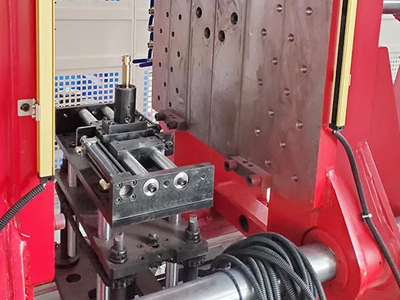

Clamping system: It has clamping plate and cylinder, linear guide, slider, transducer... Mold is fixed on the plate. All components make sure mechanical movement precision, stable and quick!

|

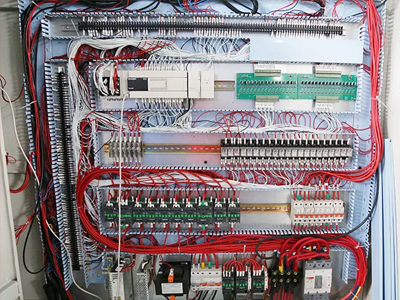

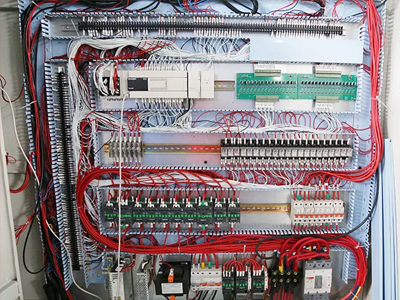

|  Electrical control: It has operation touch screen, PLC, contact switch, air switch, delay, voltage stabilized power, inverter ... We could input, modify and monitor the parameter of heating, pressure, time, alarm... to control whole machine’s action parameter by touch screen. It has two operation languages, Chinese and English!

|

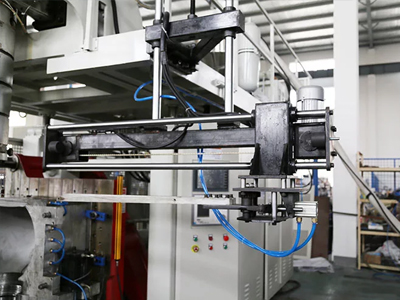

|  Hydraulic system: It has hydraulic servo motor and pump, valve, pump, oil tank, oil cooler, tube... Offer power for mechanical action, meanwhile proportional valve is controlled by oil flow pressure for transfer digital signal into mechanical action, to control the action of blow pin, clamping structure, head and extrusion! In this machine, hydraulic motor uses servo type. Servo system could save about 30% power consumption than normal AC motor, and servo motor is with less noise! |