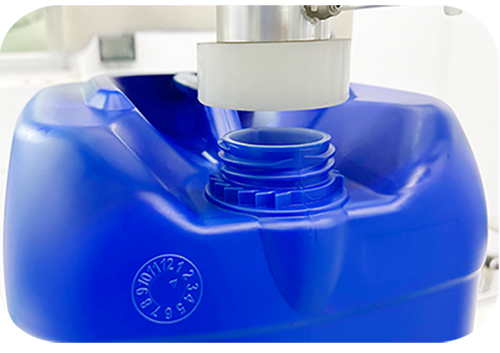

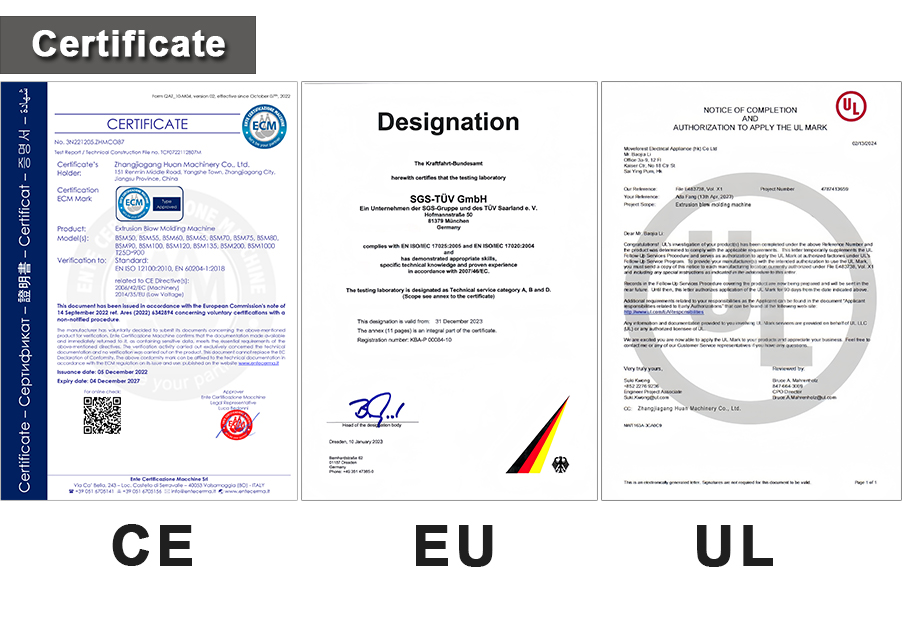

Our 25L Jerrycan blow molding manufacturing machine is a fully automatic factory equipment using German technology, capable of working 365 days without interruption. The machine's design and production process are carefully optimized to ensure maximum efficiency and minimum labor requirements, achieving true 0-labor factory operations.

In terms of production capacity, our machine is capable of outputting 3,840 products of 800 grams per day, or 3,072 products of 1,300 grams per day, which makes it very suitable for large-scale PCR production needs. In addition, the Jerrycan we produce not only meets general quality requirements, but also meets the strict standards of the United Nations to ensure product safety and reliability.

By using our 25L Jerrycan blow molding manufacturing machine, companies can significantly improve production efficiency, reduce operating costs, and ensure product quality always meets international standards. Whether for large-scale industrial production or for stringent quality control requirements, our machines are ideal.

It is accumulating machine for producing HDPE, HMWHDPE chemical, food, liquid plastic products, like 30L, 60L, 120L, 200L,220l jerrycan, plastic container, oil drum, barrel... Besides, it also could produce some different shapes plastic products like toys, road barrier, human body model or others...

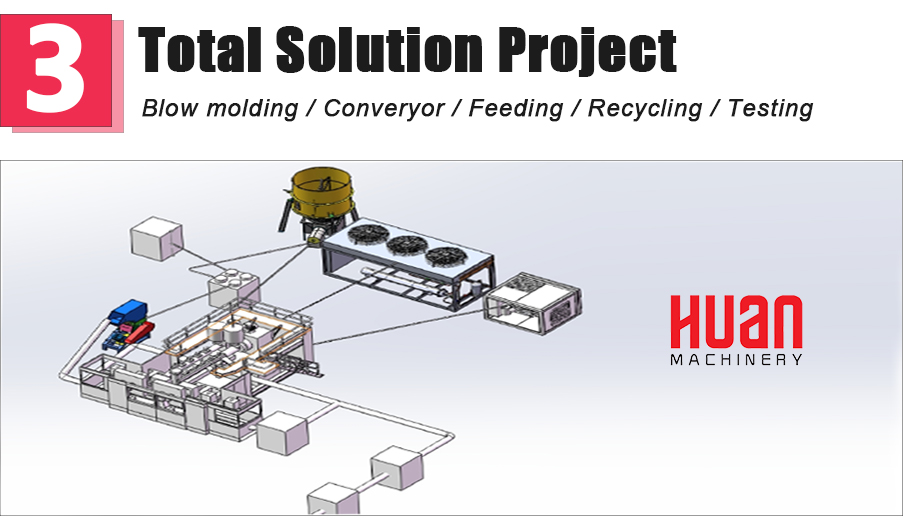

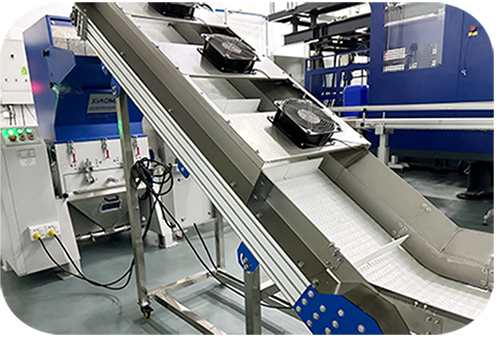

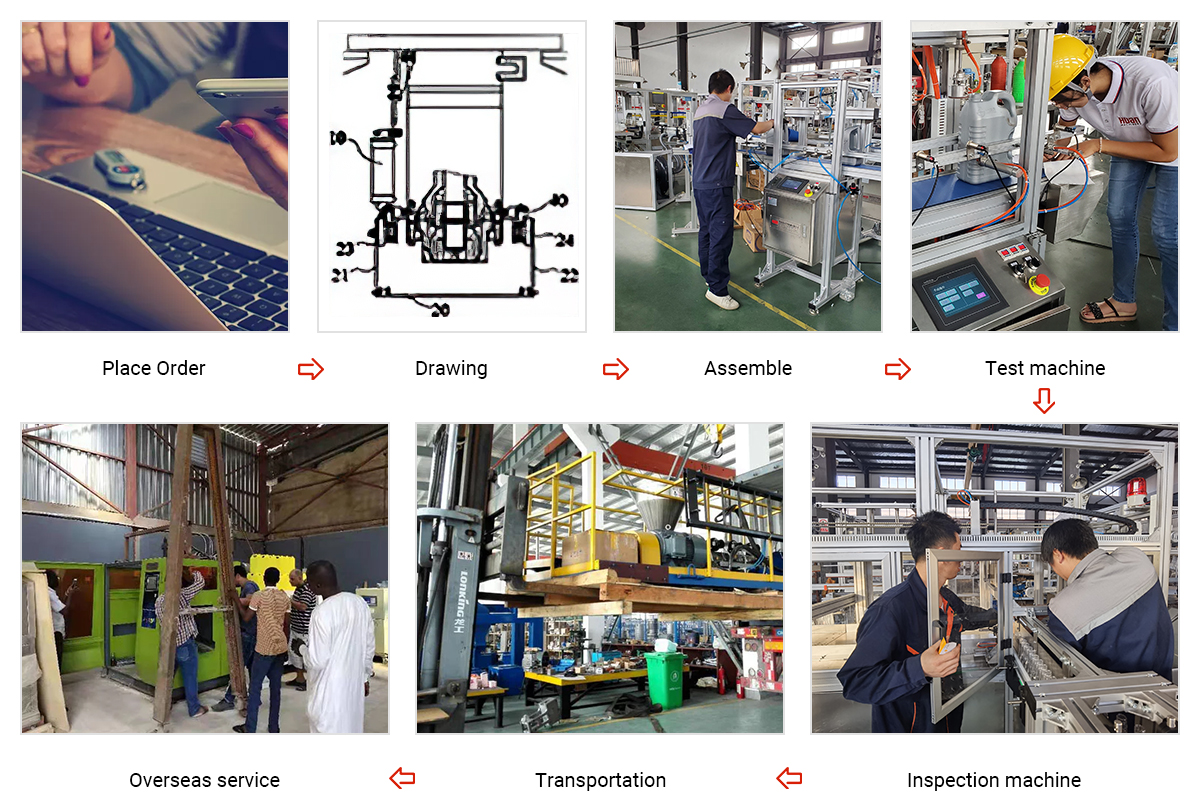

We shall supply full production line including:

auto loader

chiller

mixer

compressor

granulator

leak tester device

neck cut device

injection machine for cap

blow mold

injection mold

others