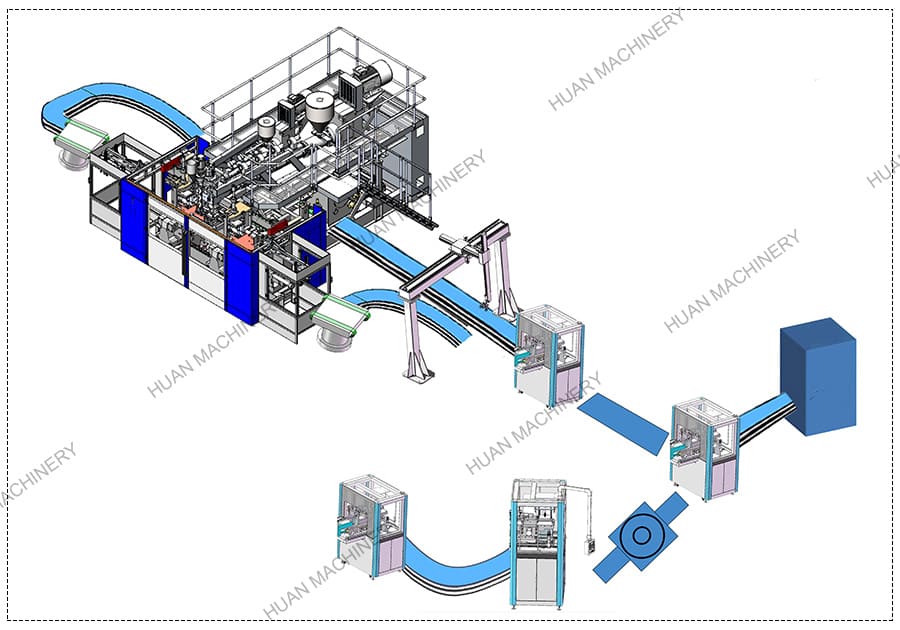

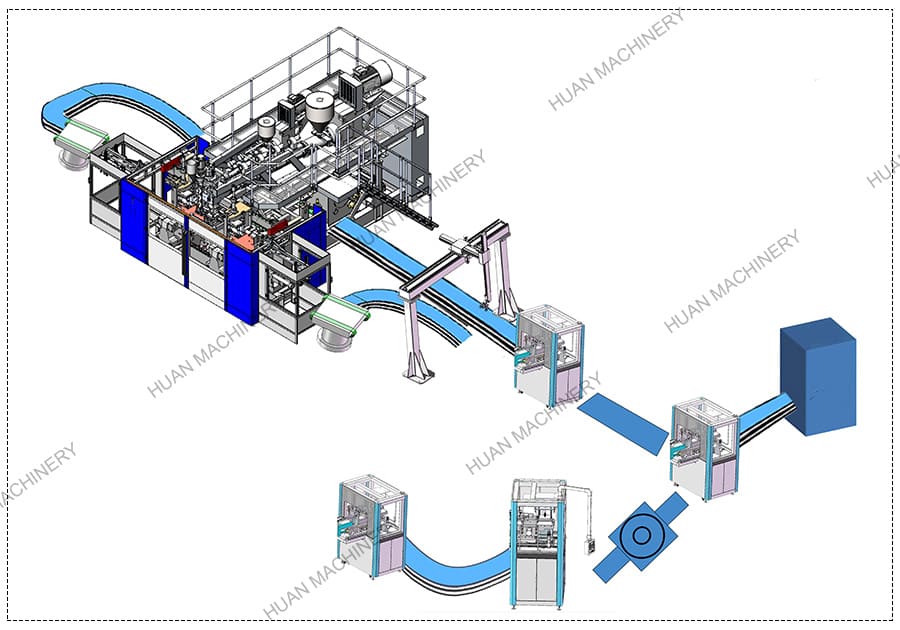

High-speed multi-layer hollow blowing molding machine, from European origin, and then through the careful improvement design of engineers, and then retain the original high reliability, high energy saving on the basis of the operation and use of more humanized, convenient. The whole machine has more than 2000 drawings, the hydraulic system adopts German Rexroth, the control system adopts Austrian Keba high-speed computer system, the extrusion system uses Italy fei servo motor, Germany Ai Cola servo pump, all use the industry's highest configuration to ensure the high reliability of the equipment. Start 3 barrels of finished products, energy consumption of 0.32kWh / Kg, reach the European level 9 energy consumption standard, for your products to improve the core competitiveness.25D represents the locking force of 25 tons, and 900 represents the mold shifting stroke of 900mm. All the templates adopt natural aging treatment + tempering process to ensure its accuracy and durability.1300g stacking bucket, forming cycle of 55s, reaching the international advanced level. The electric box is equipped with an air-conditioning system to escort the precision electrical appliances. Screw plasticizing effect is good, the product surface is exquisite, and can use cheap subbrand material, reduce the production cost.