20L plastic stackable container hdpe jerrycan blow molding machine

20L blow molding machine feature and advantage

German technology

The jerry can blow molding machine with precise & Mechanical design with top-level German technology for excellent reliability and technology. | 365 days non-stop

The jerry can machine continuous production without break, ensuring 24 hours / 7 days output to satisfy final client’s order demand. |

0-labor factory

Full automatic line which creates labor-free production, saves labor-cost and increases producer's competition in market. | High-level output

25L jerry can blow moulding machine capacity 800g jerry can — 3,840 pcs / day 1,300g jerry can — 3,072 pcs / day |

Operating system

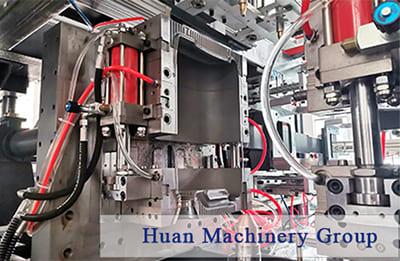

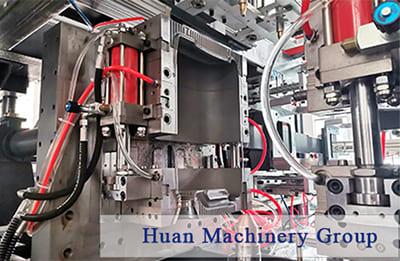

Precision-engineered 25L blow molding mold ensures uniform wall thickness, smooth finishes, and high durability for consistent.

25L blow mould

Imported Aluminum or Stainless steel material with world-advanced cooling system , which ensures guaranteed cycle time and long-running life for the blow molder.

20L blow molding machine specification

Machine model | T25D-900 jerrycan making machine |

Prdouct Capacity | 20L 25L 30L Jerrycan |

Layers | 2 | 3 |

Extruders | 90/90mm | 70/90/70mm |

Main Drive | 70/70kw | 40/70/40kw |

Max. Extrusion Output | 170/170kg/hr | 120/170/120kg/hr |

Clamping Force | 300KN | 300KN |

Average Energy Consumption | 65kw | 75kw |

Jerry can machine component

Austrian KEBA: KEBA is known for its advanced control systems that ensure precise operation and seamless integration, thereby increasing the efficiency and productivity of the blow molding process on the 25L jerry can blow molding machine.

25L Jerry Cans Blow Molding Machine Making Hdpe Jerry Can

The jerrican blow molding machine is professionally customized for the production of high quality 20L 25L 30L plastic container canister, providing a total solution. The machine is designed with precision engineering and advanced automation, making containers for chemicals, food, agrochemicals and automotive fluids, ensuring the safe storage and transportation of various liquids. Moreover, it seamlessly caters to different capacities, such as 20L jerry can, 25L hdpe canister, 30L plastic drum blow molding machines, providing versatility in your production processes.

20l Plastic Jerry Can Pe Bottle Blow Molding Making Machine

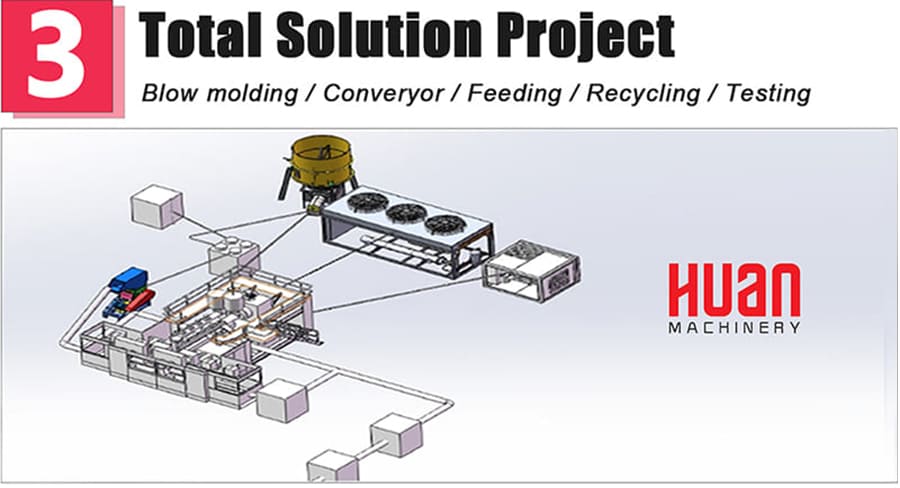

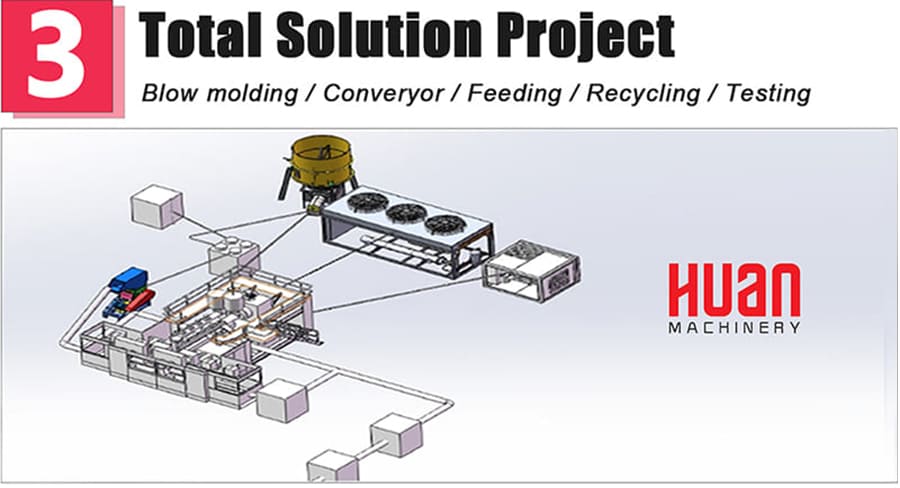

Blowing part:

Through more years research and design, our extrusion blow molding machine meet European technology. Now our machine can produce out perfect jerrycan, drum.

Feeding part:

The production line adopts the proportional weighing machine, provide accurate materials ratio.

Recycle part:

Good quality crusher and special conveyor with cooling, get the recycle material for reusing.

Inspection part:

Leak part:Make sure offer NO-LEAK jerry can for final user, we add leak testing process.

Vision inspecter:Jerrycan surface no impurity, jerrycan color correct, jerrycan neck no surplsu material, jerrycan surface smooth.

Package part:

adopt full automatic packing machine, save-labor and clean.

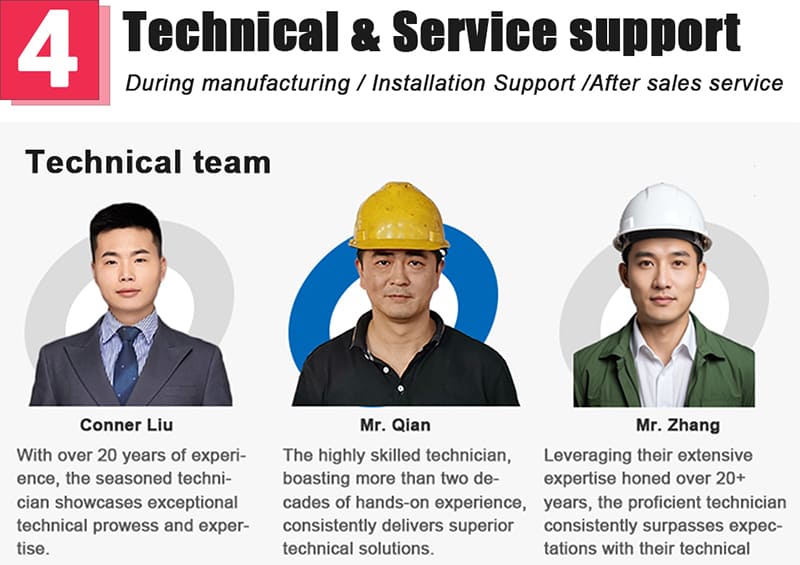

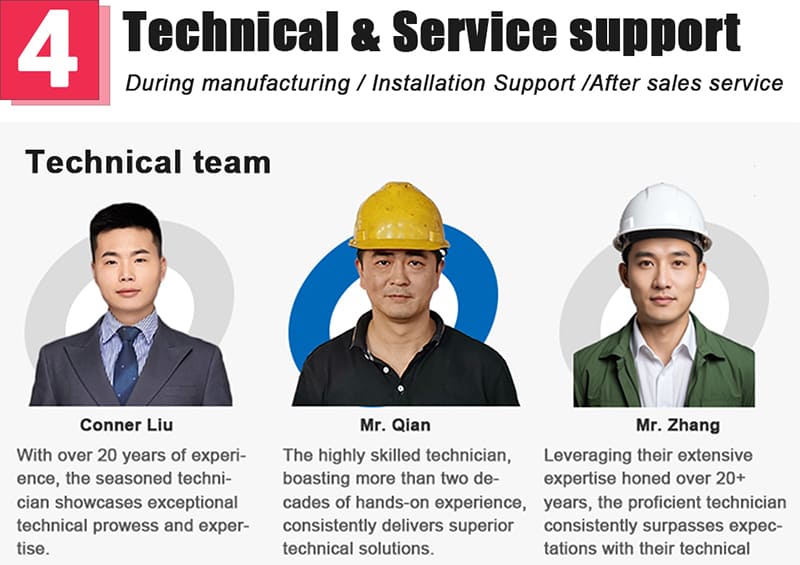

Who are we?

Total solution provider for 25L, 200L and 1000L IBC package project.

What are we?

Coex blow molding machines with Germany technology and focus on zero-labor full automation blowing line.

Why are we?

Clients realize labor-cost saving, high-level output, stable-continuous running, make client’s profit maximum.

Certificate for jerry can machine

20l Plastic Jerry Can Pe Bottle Blow Molding Making Machine

Client from EU country:

After viewing our 25L machine, they give commend:" Can’t distinguish HUAN machine and European machine, considerate & top-level EBM."

Clients from USA:

"Chinese technology is amazing, we have to try this machine."They praised.

Client from EU country:

"We are so excited that we found European-level machine with economic cost", they give comment.

Client from China

"We have to continue to purchase same model machine since our trail is successful". The boss is satisfied the machine performance.