T25D-900: Your Ultimate Solution for High-Quality Jerry Can Production

Precision and Reliability: The 20L jerry can blow molding machine adopts German design and technology, fully meets the requirements of the customers.

Continuous and Labor-Free Operation: Designed for non-stop operation, our jerry can blow moulding machine ensures a 24/7 production cycle, meeting the most demanding order requirements with ease. The fully automated process eliminates the need for manual labor, leading to significant cost savings and increased market competitiveness.

High-Volume Output: the jerry can making machine is capable of producing:

- Up to 3,840 pieces of 800g jerry cans per day

- Up to 3,072 pieces of 1,300g jerry cans per day

This high-volume output is ideal for businesses looking to meet large-scale demands efficiently.

Technical Specifications:

| Machine model | T25D-900 |

| Prdouct Capacity | 20L 25L 30L Jerry can |

| Layer | 2 | 3 |

| Extruder | 90/90mm | 70/90/70mm |

| Main Drive | 70/70kw | 40/70/40kw |

| Max. Extrusion Output | 170/170kg/hr | 120/170/120kg/hr |

| Clamping Force | 300KN | 300KN |

| Average Energy Consumption | 65kw | 75kw |

Advanced Austrian KEBA Control Systems: Equipped with KEBA's advanced control systems, our jerry can blow molding machine offers precise operation and seamless integration, enhancing the efficiency and productivity of the blow molding process.

Advanced Austrian KEBA Control Systems: Equipped with KEBA's advanced control systems, our jerry can blow molding machine offers precise operation and seamless integration, enhancing the efficiency and productivity of the blow molding process.

Customized for Versatility: The extrusion blow molding machine is professionally customized for producing high-quality plastic jerry can ion blow molding machine products. With precision engineering and advanced automation, it's suitable for a wide range of applications including chemicals, food, agrochemicals, and automotive fluids.

Versatile Production Capabilities: Our jerry can blow molding machine can cater to different capacities such as the 20l plastic jerry can making machine, hdpe jerry can blowing machine, and larger containers, providing you with the flexibility to produce various sizes of jerry cans and bottles products.

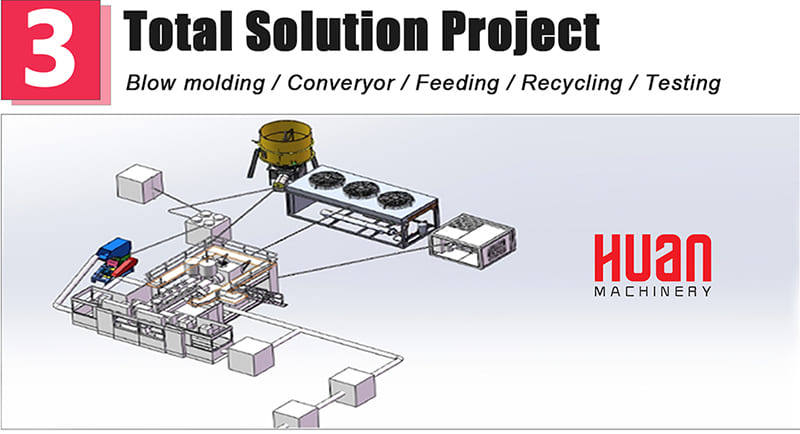

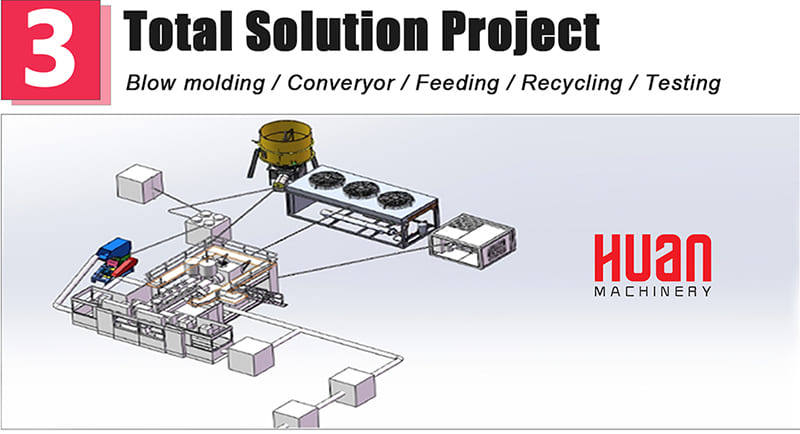

Integrated System Components:

Blowing Part:

Years of research and design have enabled our machine to produce perfect jerry cans and drums, meeting European technology standards.

Feeding Part:

Feeding Part:

The production line uses a proportional weighing machine for accurate material ratios.

Recycle Part:

Recycle Part:

A high-quality crusher and special conveyor with cooling ensure efficient recycling of materials.

Inspection and Leak Testing:

Inspection and Leak Testing:

We incorporate a leak testingprocess to guarantee NO-LEAK jerry cans.

- Vision Inspector: Ensures jerry can surface purity, correct color, smooth neck, and overall smoothness.

Full Automatic Packaging:

Full Automatic Packaging:

Our jerry can blow molding machine includes a full automatic packing machine, saving labor and maintaining a clean production environment.

Global Acclaim and Testimonials:

- EU Clients: "Can’t distinguish HUAN machine and European machine, considerate & top-level EBM."

- USA Clients: "Chinese technology is amazing, we have to try this machine."

- EU Clients: "Excited to find a European-level machine with economic cost."

- Chinese Clients: "Continuing to purchase the same model due to successful trials and satisfied machine performance."

Total Solution Provider: We offer comprehensive solutions for jerry can procution machine needs, including 25L, 200L, and 1000L IBC package projects. Our focus is on coex blow molding machines with German technology and zero-labor full automation.

Why Choose Us?

Our clients benefit from labor-cost savings, high-level output, and stable-continuous running, maximizing their profits. When you're looking for a jerry can blow molding machine price, consider the value of our high-quality, efficient, and reliable machines.

Inquire Today: For more information on our jerry cans blow molding machine or to discuss your specific production needs, contact us directly. We are committed to providing you with the best solution for your jerry can machine requirements.

Advanced Austrian

Advanced Austrian