GEFRAN complete control system is the brand of Italy, have the wide usage in European market. It is renowned for its mastery in control systems, introduces a game-changing impact on IBC blow molding. Their expertise lies in delivering precise, efficient control systems that significantly elevate the quality and efficiency of IBC blow molding.

The synergy of Gefran's cutting-edge control system lies in its seamless integration of parison thickness control and blow molding actions. By consolidating these pivotal functions into a unified system, Gefran simplifies the operational workflow, ensuring enhanced efficiency and reduced complexities. This integration not only optimizes the production process but also minimizes maintenance requirements, fostering a smoother, more streamlined production line. Gefran's solution stands out for its ability to uphold the integrity and longevity of equipment, ultimately bolstering the IBC blow molding process.

1.Integrated Control for Precise IBC Molding

Gefran's system seamlessly merges parison control and blow molding actions into a unified setup, simplifying operations and maintenance, particularly advantageous for IBC blow molding. Its comprehensive control mitigates the risk of die core damage, a common issue in other systems like Moog, caused by forced ejection due to parison thickness control failure.

This integration tailored for IBC blow molding ensures smoother operations, reduces maintenance needs, and safeguards the integrity of essential components, maintaining consistent and high-quality IBC production.

2.Enhanced Clamping Control for IBC Molding Efficiency

The Gefran complete system offers diverse slope sports data for hydraulic control, optimizing the clamping system's performance in IBC blow molding operations. This functionality ensures smooth acceleration and precise deceleration, significantly reducing hydraulic impact noise during the clamping process for IBC production. By fine-tuning the hydraulic control specifically for IBC blow molding, Gefran enhances operational efficiency and minimizes disruptive noise, resulting in a more streamlined and quieter manufacturing process.

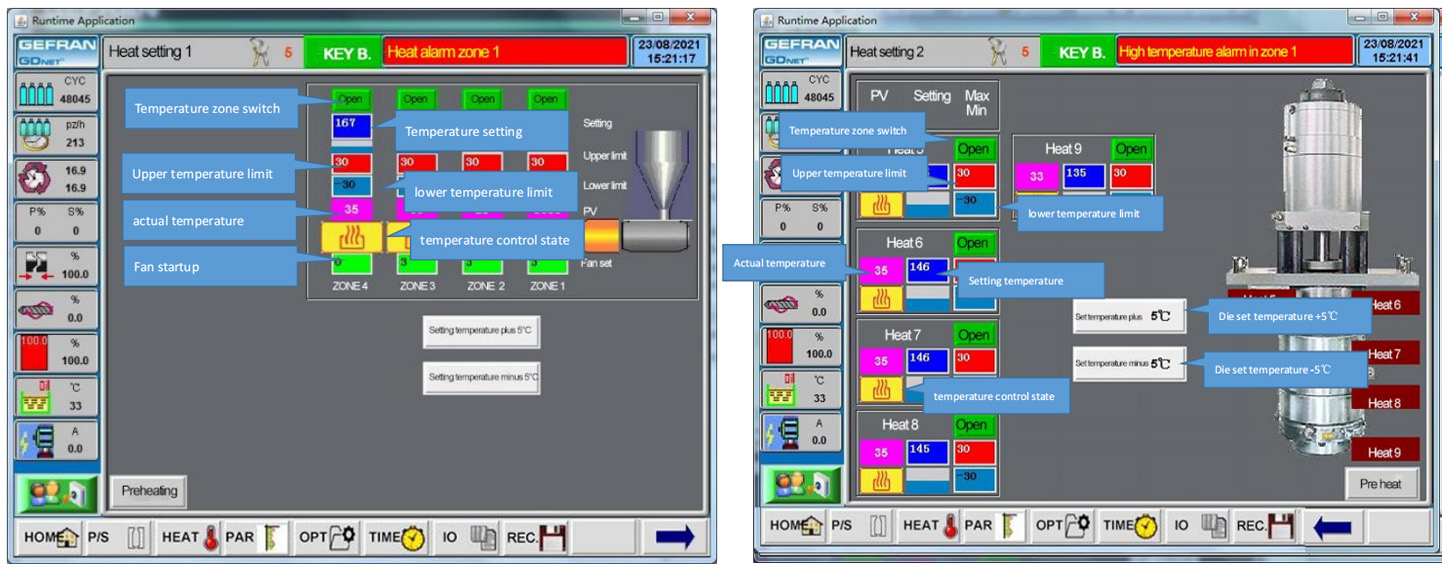

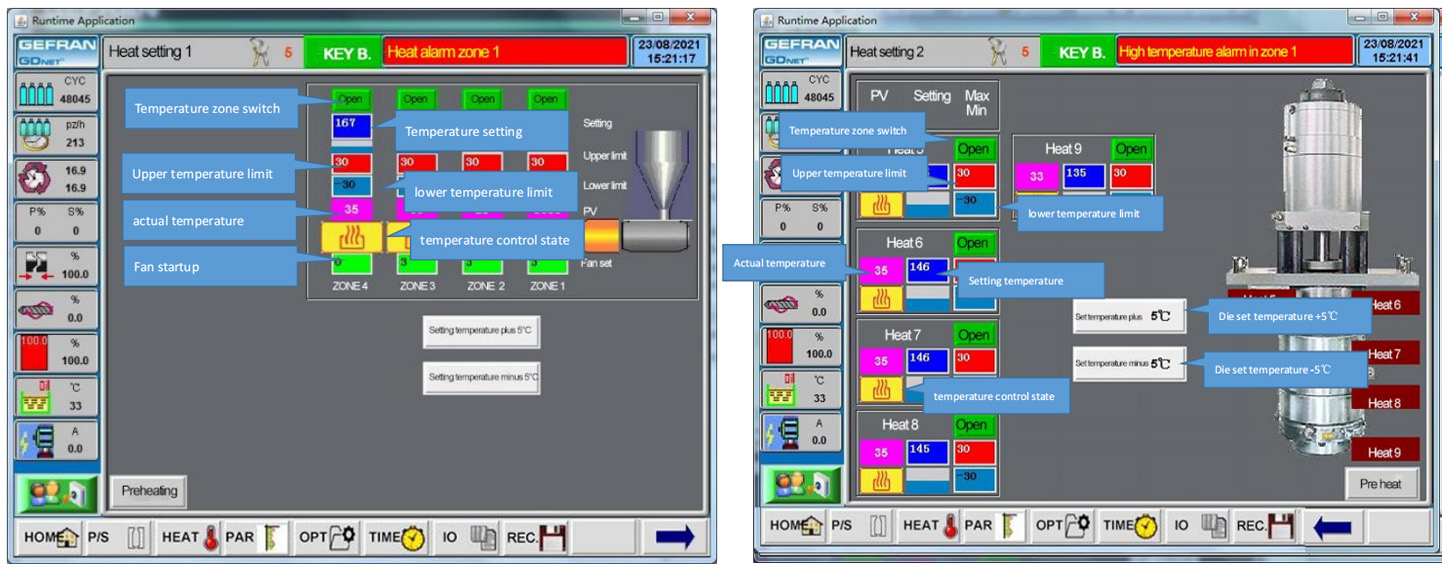

3.Precision Temperature Control for IBC Blow Molding

Gefran's system offers unparalleled temperature control precision, specifically tailored for IBC blow molding machines. Achieving temperature PID control with an outstanding precision of 0.1 degrees ensures optimal thermal management throughout the IBC blow molding process. This precise temperature regulation guarantees consistent and high-quality manufacturing, vital for creating durable and reliable IBC containers.

4.Reliable ATOS Electro-Hydraulic Proportional Valve for IBC Blow Molding

Incorporating the ATOS electro-hydraulic proportional valve, Gefran's system offers extended durability and minimal oil quality prerequisites when applied to IBC blow molding machines. Its robustness ensures prolonged usage and simplified maintenance, making it an ideal choice for the demanding requirements of IBC blow molding processes.

5.Precise Parison Control for IBC Blow Molding

GEFRAN's integrated system effectively monitors parison point and thickness during material ejection in IBC blow molding machines. It ensures precise control from the initial stage, meeting user-defined fixed values with accuracy. This feature guarantees consistent parison control throughout the entire process, contributing to superior quality IBC production.

6.Remote Program Modification for Versatile IBC Molding

GEFRAN's system allows remote program alterations in IBC blow molding machines, enabling adjustments to machine actions. This feature facilitates the production of IBC tanks, enhancing the flexibility and adaptability of the molding process.

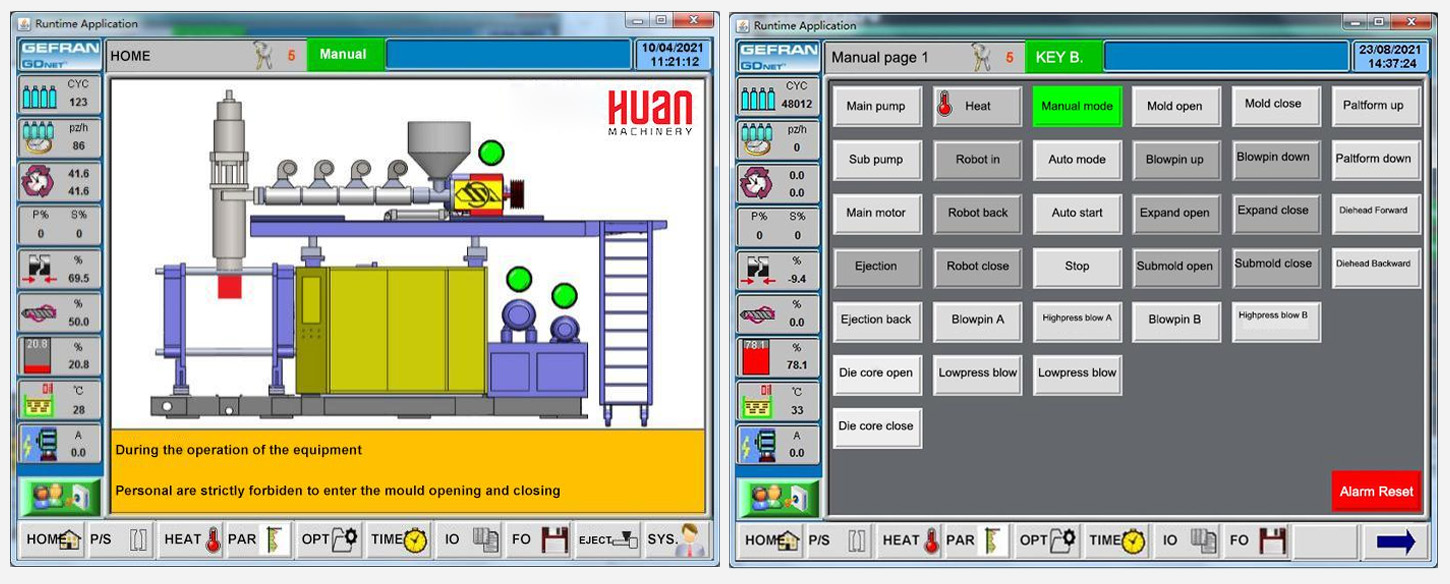

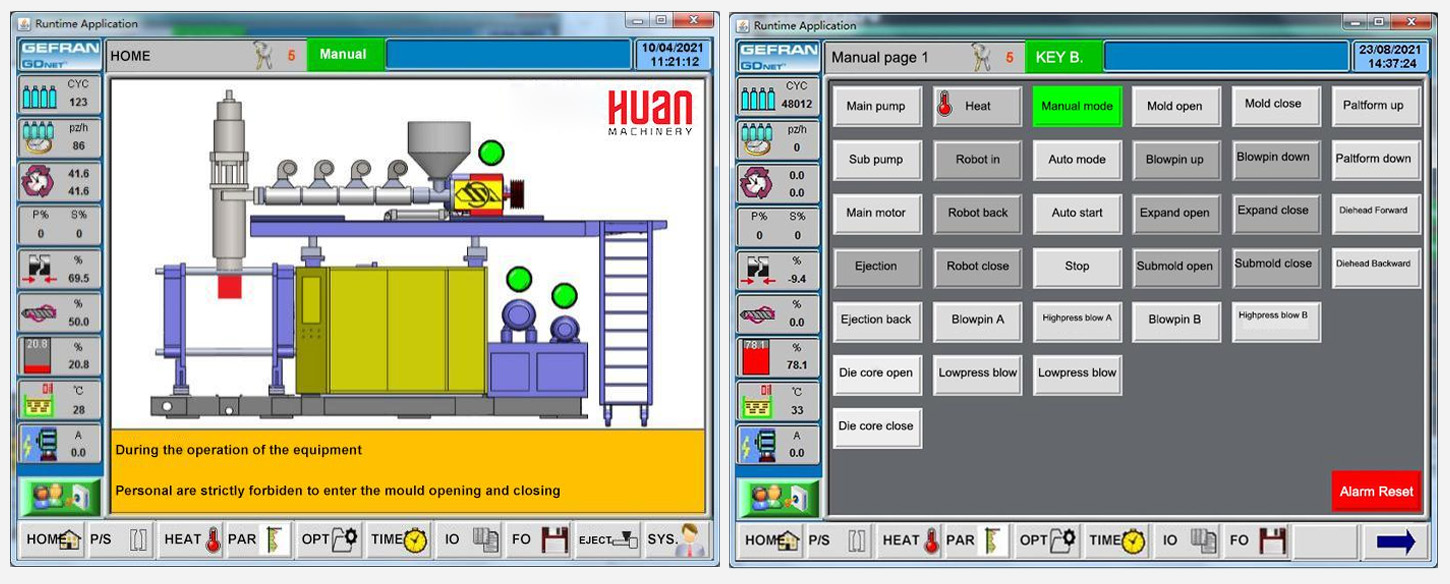

7.User-Friendly Operation Pages Tailored for IBC Blow Molding Machines

GEFRAN's system offers convenient operation pages designed specifically for IBC blow molding machines. These pages facilitate user interaction, encompassing various data settings and failure analysis. Notably, the system includes dedicated pages for parison thickness settings and data feedback, streamlining the molding process for users.

8.Streamlined Operation: GEFRAN's Touch Screen & Keyboard for IBC Blow Molding

The GEFRAN control system integrates a touch screen with an external keyboard, ensuring seamless operation and monitoring for IBC blow molding machines. This setup prevents interference between operations and monitoring while also minimizing wear on the touch screen.

Gefran's control system stands as a pivotal asset in IBC blow molding, offering precision, operational efficiency, user-friendly interfaces, and adaptable functionalities. The integration of multiple functions into one system ensures smoother operations, reduced maintenance needs, and enhanced productivity. Businesses keen on optimizing their IBC blow molding processes should strongly consider Gefran's tailored solutions. Embracing Gefran's advanced technology promises heightened efficiency, improved precision, and a streamlined operation, ultimately leading to higher-quality IBC tote products. Explore Gefran's offerings today to revolutionize your IBC tank blow molding processes and gain a competitive edge in the market.