Turkish customer needs

In July 2023, Turkish customers visited China to inspect and discuss the IBC machines with our company. After visiting our Chinese customer's factory, the customers highly recognized the stability and design technology of our IBC machines. They requested a fully automatic IBC machine with a daily production capacity of 500 tons.

Currently, Turkish customers purchase many IBC containers from various countries to pack their liquid chemicals, which is not cheap. In the near future, they plan to use our IBC machines to reduce packaging costs by 50%.

This is also our company's first customer in the Turkish market, which will significantly promote our development in surrounding markets.

The successful delivery of this IBC machine to the Turkish customers marks the first step in our cooperation on the IBC machine. We will continue to provide more IBC machines to Turkish customers in the future.

Successful delivery and follow-up support

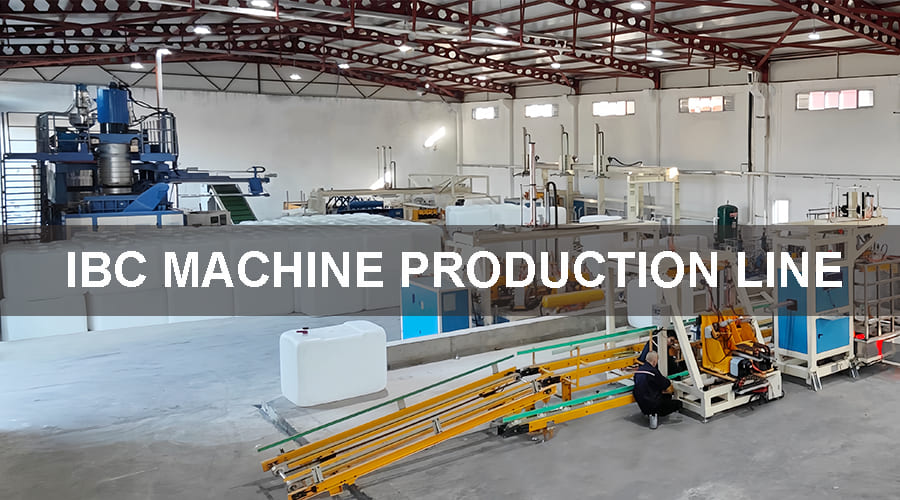

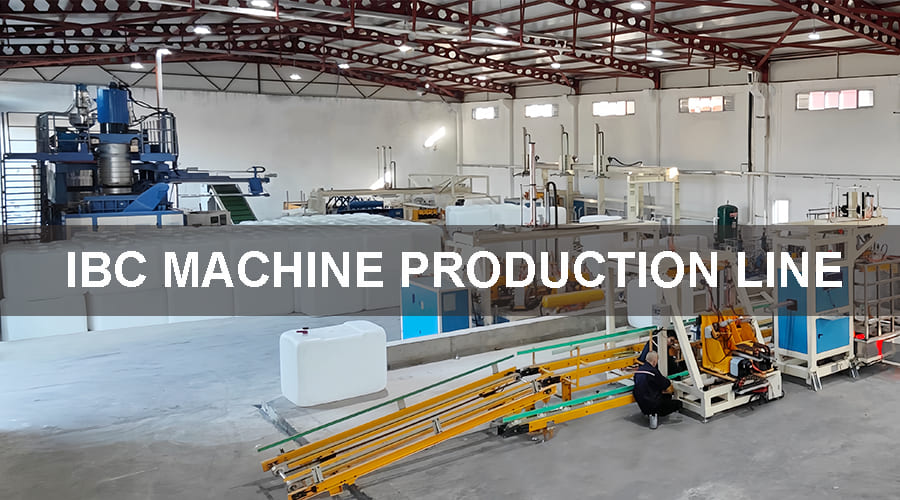

In September 2023, the customers confirmed the order. After three months of intense preparation, we completed the IBC machine shipment at the end of December. Following three days of loading, more than 10 containers arrived at the Turkish customer's port in early February 2024. HUAN MACHINERY dispatched four engineers to conduct one week of debugging and one week of training, enabling the customers to learn how to operate and maintain the IBC production line equipment.

The entire process of IBC machine production line producing, debugging, shipment, and debugging in the customer's workshop was completed by our HUAN team in collaboration.

IBC Machine technical features

Our IBC machine production line is fully automatic, with only 9 employees needed to achieve a daily production capacity of 600 tons, and a production efficiency of 9kw per ton.

Currently, China's IBC tank machine is at the forefront of the world. By learning from advanced German technology, we have achieved precise control of IBC HDPE inner tank thickness, ranging from 1.5mm to 2.3mm. The IBC tank cage welding machine is also at the world's advanced level, ensuring sturdy IBC cage frames that meet global standards for torque testing.

IBC Tank Quality and Certification

Our IBC tanks have successfully passed a 1.9M drop test, a one-hour vibration test, and a 200ka hydraulic test. The IBC machine produces 1000L IBC tanks suitable for certification by ship classification societies worldwide.

We will continue to research the wall thickness control of IBC blow molding machines, especially PWDS wall thickness control, to better control wall thickness uniformity and save on the cost of producing IBC machines.

International Standard Production

We strictly adhere to CE standards in the production of the whole IBC machines, using European brands for important components such as SIMENS, FLENDER, GEFRAN, etc. These brands are popular with European and American customers, facilitating quick after-sales service solutions locally.

Customer satisfaction and market feedback

The Turkish customers are very satisfied and acceptable with our IBC machines. They have already publicly praised their IBC machines for their excellent performance and hope that others will understand their production process and IBC machines.

This IBC machine production line is currently operating excellently in the Turkish customer's workshop. We welcome friends who are preparing to start IBC tank production to visit our Turkish IBC machines. I am happy to provide a detailed introduction to our IBC machines.

After delivering the IBC machines, we will provide strong after-sales support in terms of IBC raw materials. We are ready to supply customers with complete sets of IBC raw materials, including valves, galvanized sheets, galvanized pipes, etc.

Due to the many advantages of IBC tanks, such as cost savings in packaging, convenient filling, easy transportation with bottom trays, and easy liquid extraction through bottom valves, there is a significant global demand for these IBC container. As a result, the demand for IBC machines in the blow molding industry is surging.

Company Vision for IBC Machine

We are specializes in the production and sale of IBC machines. Currently, we have 188 IBC machines and cases in domestic and international markets. In the future, we will greet international friends visiting our IBC machines with a more sincere attitude. We hope our IBC machines can reach more countries, providing perfect IBC machine production line solutions to those interested in IBC machines.

Of course, there are areas for improvement in our delivery of this IBC production line, such as missing some free accessories. We will pay extra attention to these aspects in the future.

Meanwhile, if given the opportunity, we hope to provide more training on our IBC machine operation to customers, enabling their workshop workers to master the skills quickly and create more value for them.

HOT PRODUCT