In today’s world of plastic manufacturing, material selection plays a critical role in the efficiency and quality of the final product. For 25L jerry can manufacturers, choosing the right material can significantly impact production efficiency, durability, and overall product performance. Proper material selection not only ensures compliance with industry standards, but also improves the sustainability and cost-effectiveness of the production process.

By understanding the characteristics, benefits, and considerations of various materials, manufacturers can optimize production processes, achieve maximum efficiency, and produce high-quality, aesthetically pleasing jerry cans that meet market demands.

Jerrycan is a versatile portable container that is widely used in various industries due to its durability and ability to safely store liquids.

Raw material for 25L jerry can blow molding

The types of materials commonly used in 25L jerrycan extrusion blow molding include HDPE, PCR materials, colored resins, and deburring materials.

A. HDPE (High Density Polyethylene)

HDPE is the standard plastic material used to produce jerrycans, and it has several characteristics:

- Mechanical properties: HDPE has excellent strength and durability, making it ideal for applications where the container needs to withstand impact and rough handling.

- Chemical stability: It is chemically inert, making the jerry can resistant to acids and alkalis.

- Recyclability: HDPE can be recycled, which helps achieve a more sustainable production process.

B. PCR material (post-consumer recycled)

PCR plastic is a post-consumer recycled material that plays an important role in oil drum production:

- Reduce environmental pollution: Using PCR material reduces the amount of new HDPE required, thereby protecting the environment and promoting the recycling of plastics.

- Double-layer application: For food-grade oil drums, a double-layer approach is recommended, with an inner layer of HDPE and an outer layer of PCR. This not only enhances the structural integrity of the container, but also meets food safety standards.

C. Colored resins

Colored resins are used to produce jerry cans of different colors, usually blue, black, etc.:

1. Aesthetics: Colored resins can create visually appealing bottles, meeting the market's demand for aesthetic packaging.

2. Lightproofing: In particular, black resins are used for their lightproofing properties, which is beneficial for storing light-sensitive substances, such as certain chemicals or pharmaceuticals.

D. Plastic defalshing materials

Plastic barrel defalshing is a process that occurs during jerrycan production and involves removing excess material or "burrs" from the edges of plastic parts:

- Cost reduction: The material removed during defalshing can be reused in the production process by crushing it in a crusher, thereby reducing costs and waste.

- Environmental protection: By reusing defalshing materials, the impact of production on the environment can be minimized.

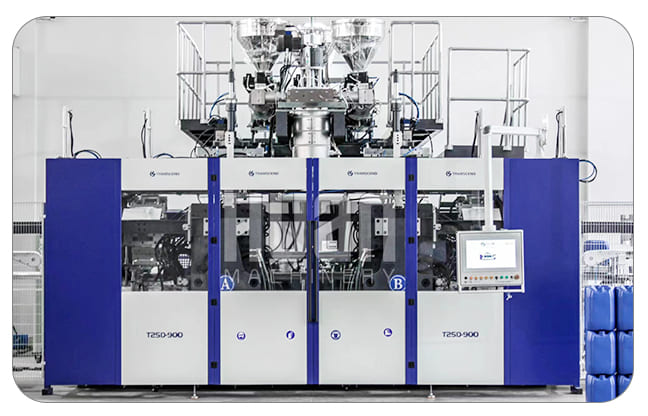

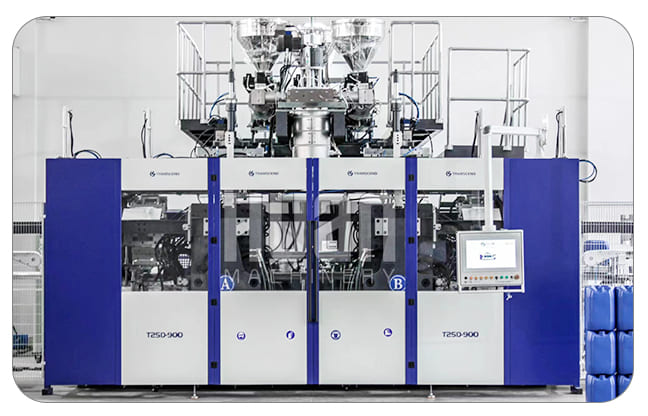

E. Production technology

HUAN MACHINERY's two-layer extrusion blow molding machine's production technology is mature, and there is also a 3 layer jerry can blow molding machine that can efficiently produce jerrycan with multiple layers of materials. This technology is essential to achieve the desired performance of the final product, such as strength, durability, and safety.

Recommended HDPE grades for 25L jerry can production

For the production of 25L HDPE jerrycan (blow molding process), the following HDPE raw material grades are generally more suitable:

1. HDPE 7070 - This HDPE has good fluidity and excellent blow molding performance, suitable for the production of large-capacity containers.

2. HDPE 7350 - This grade provides excellent toughness and strength, and is stable during the blow molding process, suitable for jerrycans that require durability.

3. HDPE 7740 - Has excellent impact resistance and chemical resistance, suitable for making durable industrial containers.

4. HDPE 7370 - This material has high fluidity and good dimensional stability, which is very suitable for blow molding large-volume containers.

These HDPE grades can ensure the required strength, toughness and overall stability of the product during the blow molding process. Choosing the right grade can help improve production efficiency and the quality of the final product.

What are the well-known brands to choose from:

1. SABIC- SABIC® HDPE: such as SABIC® HDPE 5200 and SABIC® HDPE 5300, these grades provide excellent processing performance and durability.

2. ExxonMobil- ExxonMobil HDPE: such as ExxonMobil™ HDPE 55S and ExxonMobil™ HDPE 80M, these materials perform well in the blow molding process and are suitable for the production of large-capacity containers.

3. Dow Chemical- DOW® HDPE: such as DOW® HDPE 5502 and DOW® HDPE 7300, these grades have excellent processing performance and toughness.

4. LyondellBasell- Hostalen®: such as Hostalen® AC 7010 and Hostalen® GC 5050, these materials are suitable for blow molding processes and provide good strength and stability.

5. Chevron Phillips- Marlex®: Such as Marlex® HDPE 2000 series, these grades have excellent fluidity and blow molding performance.

These brands of HDPE raw materials are widely used in blow molding process. Choosing the right brand and grade can ensure the production of high-quality 25L HDPE jerrycan. If you are not sure whether you can use other brands of HDPE raw materials, you can send us the physical property table to confirm.

Choose good raw materials and also choose the right 25L jerry can blow molding machine to cooperate with each other and achieve high production efficiency.

The 25L jerry can blow molding machine produced by HUAN Machinery can match a variety of HDPE raw materials, with low energy consumption and produces 125 jerrycans per hour.

If you also have higher requirements for 25L jerrycan, please contact me. We can help you arrange the factory layout for free and help you complete production in the most compact space.