What is an IBC tank?

IBC tank can also be called IBC tote, IBC container, and the Russian market will call it EUROCUBE (ЕВРОКУI). Its full name is intermediate bulk container.

It is an important tool for modern storage and transportation of liquid products. The container barrel is composed of an inner container and a metal frame. The inner container is blow-molded with high molecular weight and high-density polyethylene, which has high strength, corrosion resistance and good hygiene. Widely used in chemical, pharmaceutical, food, paint, oil and other industries. It is an essential tool for modern storage and transportation of liquid products.

IBC tank famous brands in the world

Germany SCHUTZ

https://www.schuetz-packaging.net/

American Greif

https://www.greif.com/

Germany MAUSER

https://mauserpackaging.com/

Italy MASCHIO

https://www.maschiopack.de/

Advantage of IBC tanks

IBC (Intermediate Bulk Container) has several advantages compared to a 220-liter drum:

1. Saving Raw Material Consumption: The inner capacity of an IBC is 1000 liters, with an HDPE container weight of 14kg. Assuming HDPE raw material costs USD 1000 per ton, the material cost for the inner tank of one IBC is USD 14, while the 220-liter drum requires USD 10.

2. Less Drainage Residue:The drainage valve of the IBC is located at the bottom, making it easy to discharge without leaving residues.

3. High Filling Efficiency: IBCs can have different openings tailored to various materials, with a maximum diameter of 650mm, making them more convenient for filling.

4. All Parts Can Be Recycled and Reused: The inner part of the IBC can be reused up to 20 times, requiring only a replacement of the outer frame, resulting in cost savings.

5. Convenient Transportation and Moving by Forklift: IBCs have a pallet at the bottom, allowing easy insertion for transportation using a forklift.

6. Extra-Highly Saving Stocking Space by 35%:IBCs are square-shaped, saving more space when stacked compared to the circular shape of a 220-liter drum.

Additionally, the testing standards for IBCs are generally higher than those for 220-liter drums, covering aspects such as drop tests, vibration resistance, and freezing. Meeting testing requirements for 200-liter drums often involves reinforcing and thickening the double-ring section, incurring additional material costs.

Types of IBC (Intermediate Bulk Container):

1. Standard 1000L (275 gallon)IBC Tank:

- IBC cap size Sizes: 150mm/225mm/650mm

- Valve Options: DN50/DN80

- Color Options: Black or Blue light-shielding tank

- Full Volume: 1050L

- Nominal Volume: 1000L

- IBC Size: 1200*1000*1500mm

- Thickness: 1.5-2mm

(Uniform wall thickness reduces raw material costs. When designing the IBC tank machine production line, we pay special attention to the runner design of the die head and the special design of the die. The corners of the IBC tank liner are slightly thinner and the middle is slightly thicker.)

- Frame Material: Galvanized steel

- Forklift Opening Size: 100mm

- Tank Material: 100% HDPE

- Signboard: 2pcs

- Base Angle: 4pcs

- Middle Corner: 1pc

- Inner Container Weight: 14kg

- Total Weight: 55±1KGS

2. Vertical 500L IBC Tank:

- Half the width of the 1000L tank

3. Horizontal 500L IBC Tank:

- Half the height of the 1000L tank

4. IBC Tanks with Large Mouth Diameters (500L/1000L):

- Uses 650mm diameter lids

- Suitable for high concentration and high viscosity materials

- Valve selection: DN80 for higher flow rates

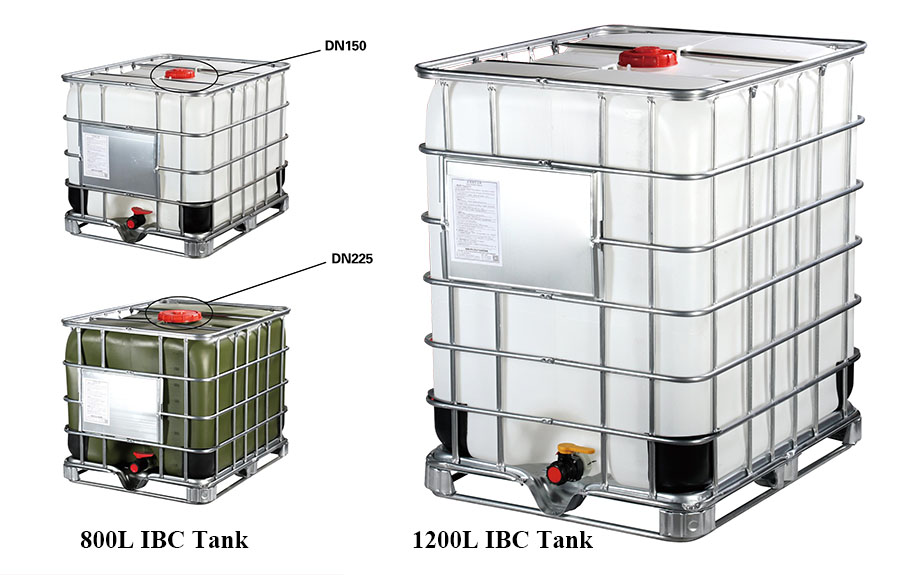

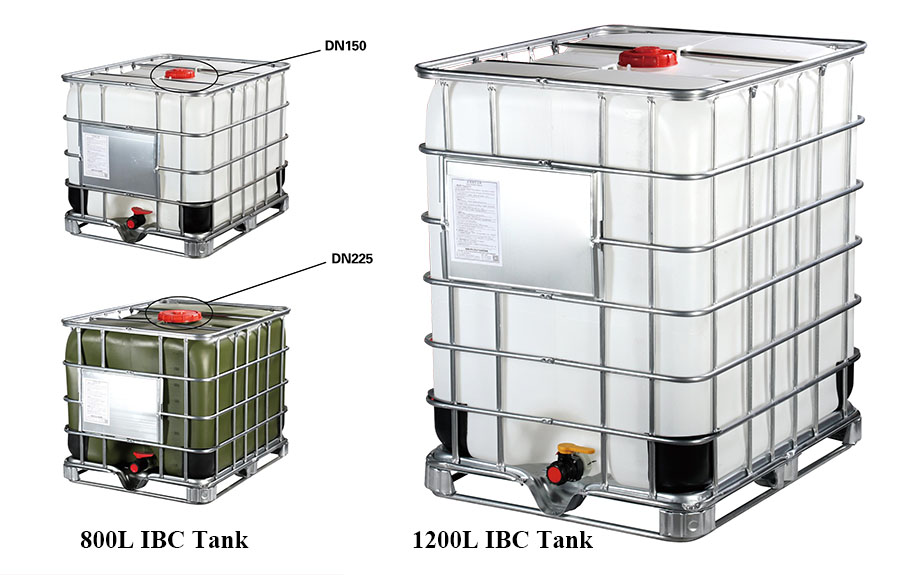

5. Other Capacities:

- 800L and 1200L IBC Tanks available

6. Specialized IBC Types:

- Lifting IBC Tank:

- Features reinforced columns for lifting operations in confined spaces

- Suitable for ship and space-restricted lifting operations

- Reinforced columns ensure stable lifting without swaying

- Stainless Steel Frame IBC Tank:

- Utilizes stainless steel frame for superior acid, alkali, and corrosion resistance

- Contrasts with traditional galvanized steel, offering enhanced durability

This diverse range of IBC tanks caters to various needs, providing options for different capacities, orientations, and material requirements.

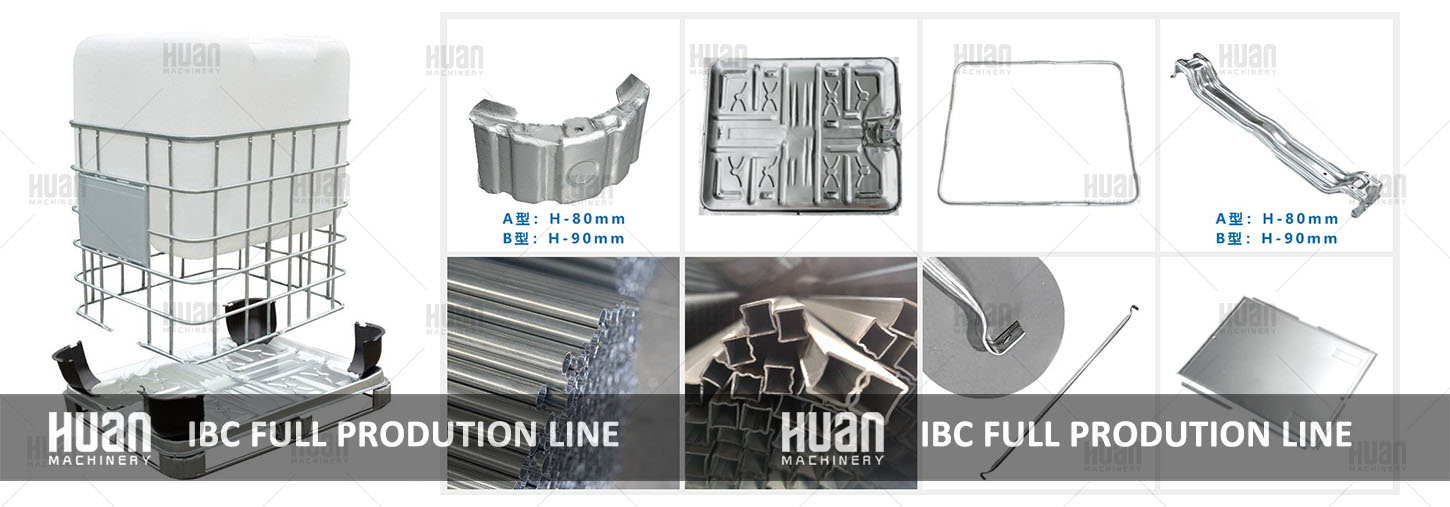

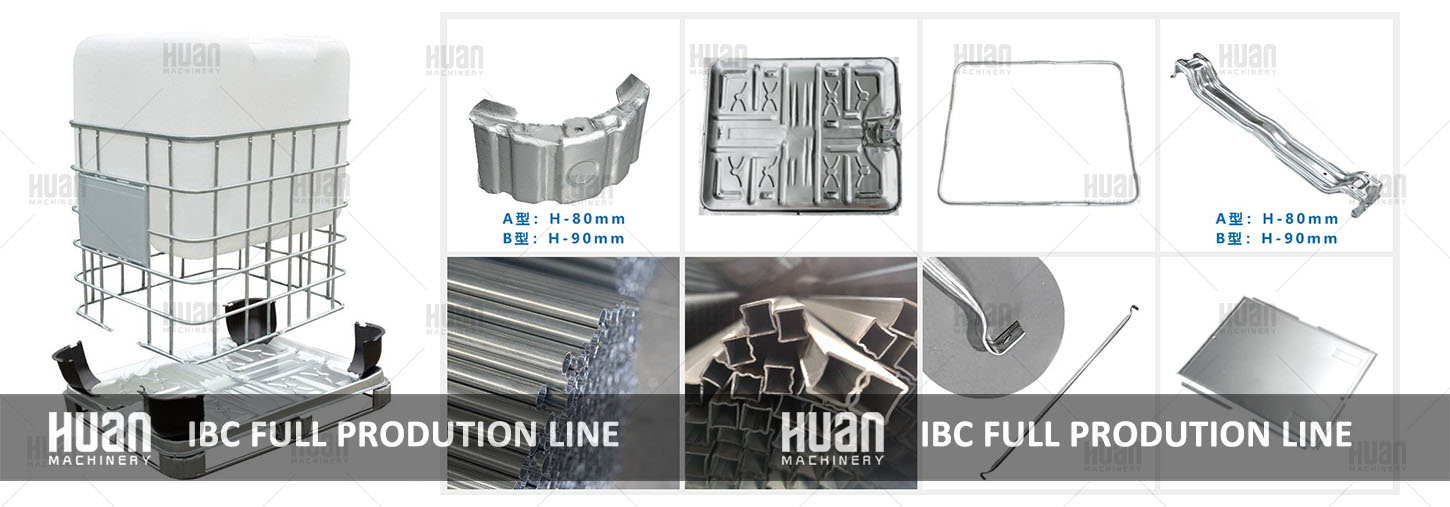

Components of an IBC (Intermediate Bulk Container):

1. IBC Cap:

- A cap to secure the top of the IBC.

2. Pull Rods (2):

- Rods used for handling and maneuvering the IBC.

3. HDPE Inner IBC Tank:

- The main container made of High-Density Polyethylene.

4. P-Shaped Pipe (1):

- A pipe in the shape of the letter 'P' for specific structural support.

5. Galvanized Vertical Pipes (20):

- Includes 16 perforated pipes and 4 non-perforated embossed pipes for structural integrity.

6. Horizontal Pipes (5):

- Consists of 4 long pipes and 1 short pipe for additional support.

7. Identification Tags (2):

- Tags for labeling and identification purposes.

8. Black Plastic Base Corners (4):

- Corners made of black plastic for stability and protection.

9. IBC Valve and Discharge Pipe (1 each):

- Valve for controlling the release of contents and a pipe for discharge.

10. Metal Bottom Support:

- A metal structure at the bottom for added stability.

11. Horizontal Beam (1):

- A beam providing horizontal support.

12. Bottom Pipe (1):

- A pipe at the bottom for structural support.

13. Metal Base Corners (4) and Middle Foot (1):

- Metal components for additional support and stability.

Each of these components plays a crucial role in the structure and functionality of the IBC, contributing to its durability and ease of use.

Intermediate Bulk Containers (IBCs) offer a versatile solution for the storage and transportation of liquids and bulk materials. The standard 1000L IBC tank, with its varied specifications including filling sizes, valve options, and color choices, represents a widely used and efficient option in the industry. Additionally, the diverse range of IBC types, such as vertical, horizontal, and those with different capacities, caters to specific needs. The composition of an IBC involves a meticulous arrangement of components, from the HDPE inner tank to galvanized steel structures, ensuring durability and functionality. Specialized IBC types, including lifting and stainless steel frame variations, further expand the application possibilities. Altogether, IBCs stand out for their cost-effective material consumption, reduced drainage residue, high filling efficiency, recyclability, and convenient handling features, making them a preferred choice for various industrial and logistical applications.

HOT PRODUCT