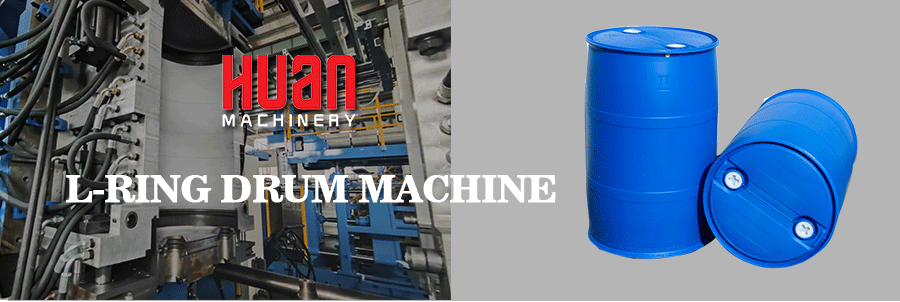

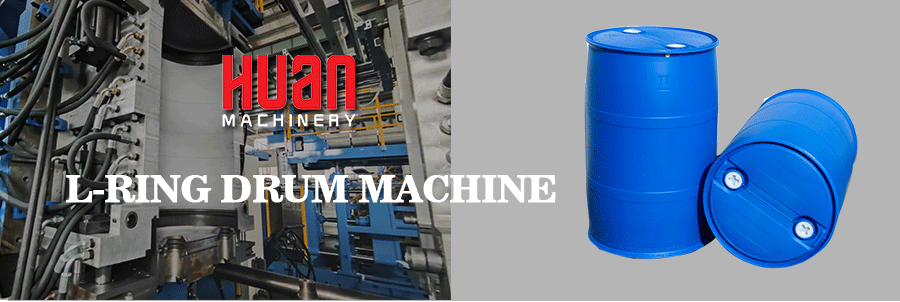

Extrusion blow mold machine of blue drum 200 ltr machine

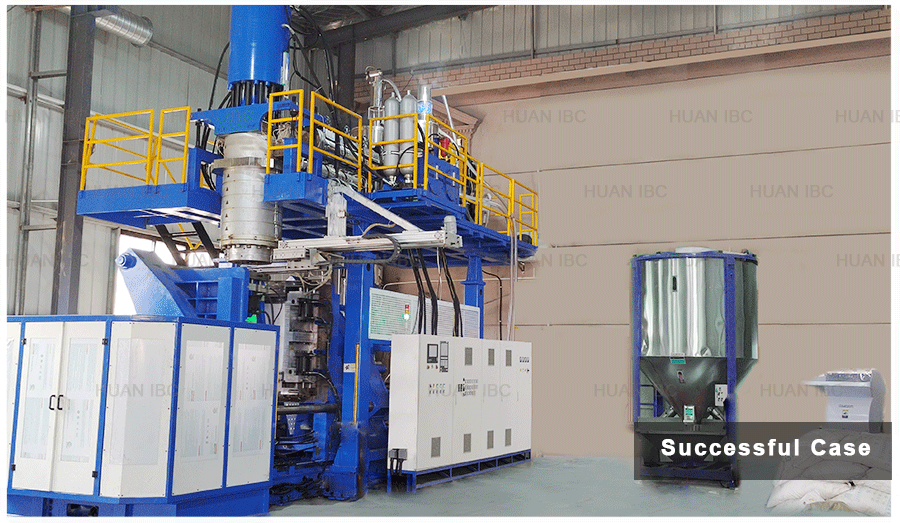

200L Blow Molding Machine for Double L Ring Drums is meticulously engineered to meet the exacting demands of industrial packaging, offering precision, reliability, and efficiency for the production of high-quality drums. With customizable options including 2 layers, 3 layers, or single layer configurations, it ensures versatility to match diverse production needs,high productivity 720 pcs per day.

L-ring drum blowing

200L hdpe drum extrusion blow molding machine can produce 220 litre open top blue drum with high speed.

Operating system

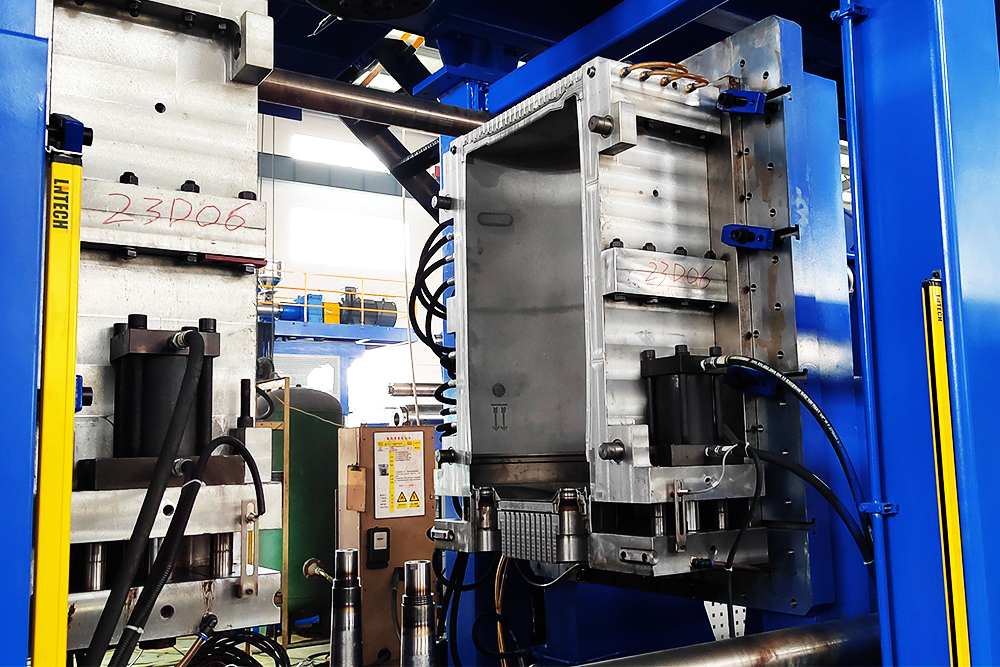

Precision-engineered 200L 220L HDPE drum tank blow molding mold ensures uniformwall thickness, smooth finishes, and high durability for consistent.

L-ring drum blow mold

Aluminum material with high hardness, advanced design cooling system which ensures high output 30 drums per hour.

Specification

| Machine Model | BSM200 |

| Product Capacity | 200L 220L HDPE Drum |

| Layers | 2 | 3 |

| Extruders | 120mm/120mm | 90mm/90mm/90mm |

| Main Drive | 110kw/110kw | 75kw/75kw/75kw |

| Max. Extrusion Output | 800kg/hr | 800kg/hr |

| Clamping Force | 1200KN | 1200KN |

| Average Energy Consumption | 130kw | 150kw |

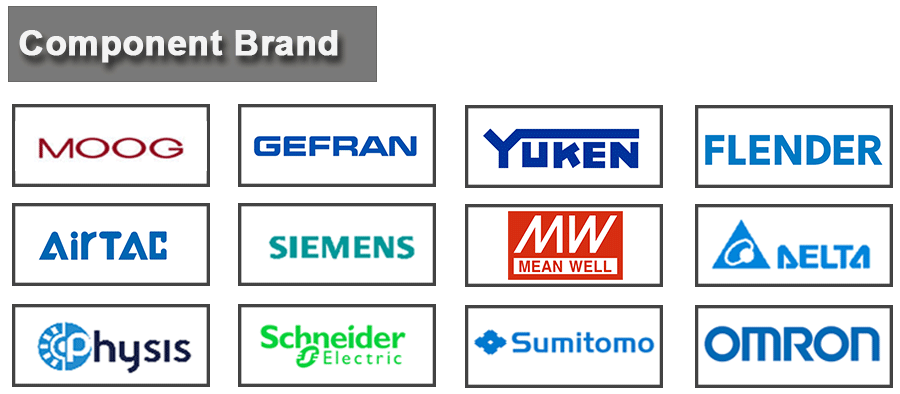

Italian GEFRAN: GEFRAN is known for its advanced control systems that ensure precise operation and seamless integration, thereby increasing the efficiency and productivity of the blow molding process on the IBC tank blowing machine.

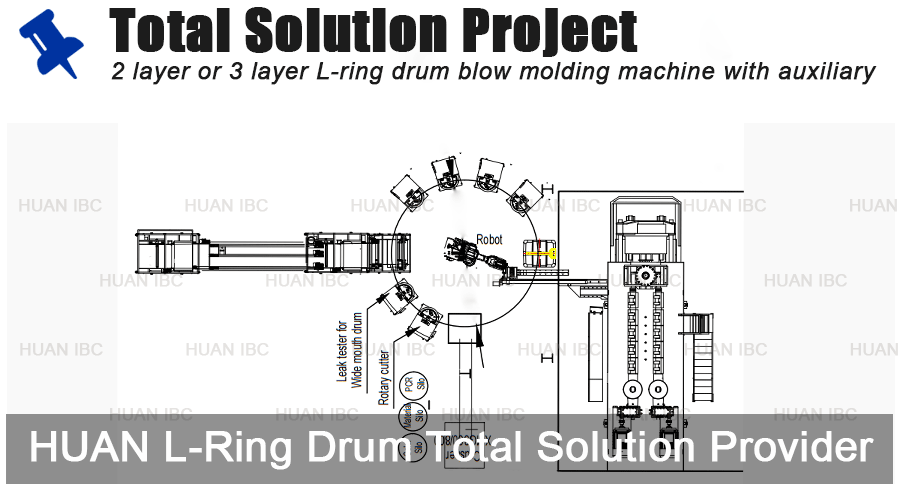

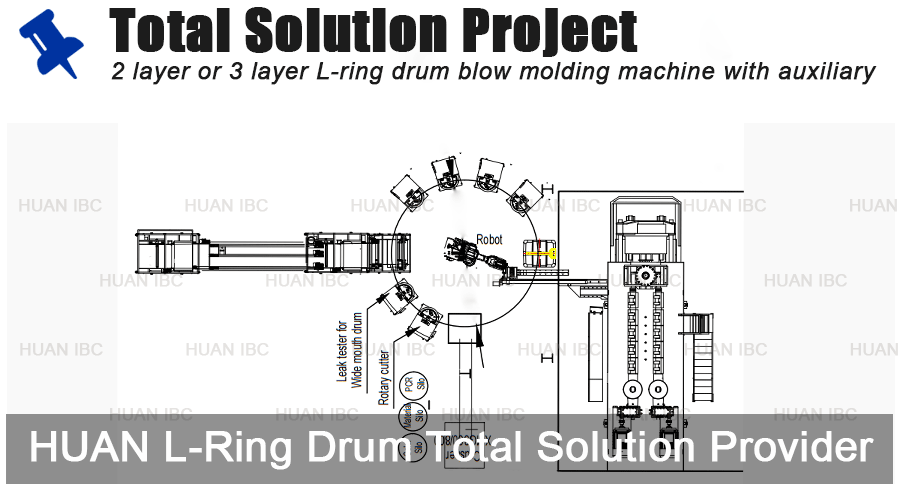

Drum blowing part:

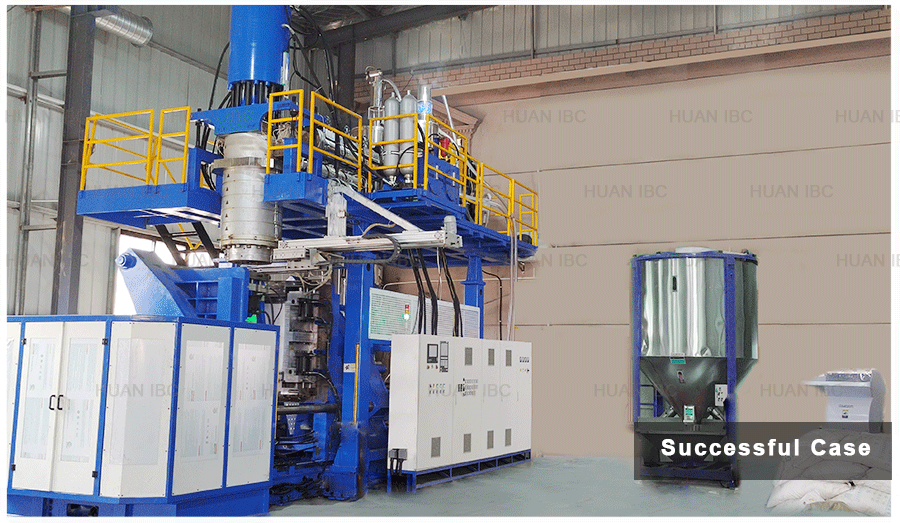

Through 15 years reaserch and design,our Hdpe drum machine adopts European technology and

the drum neck is better shaped.

Posting-cooling:

Shape the 200L/220L L-Ring drum to ensure

the drum strength.

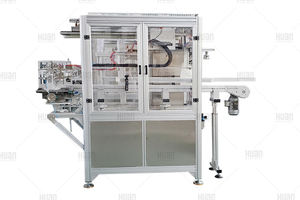

Leak tester:

Make sure no-leak 200L/220L Hdpe drumfor

final user, automatic leak tester is optional.

Robot arm:

Strong bearing capacity

Good safety performance

Reduce labor