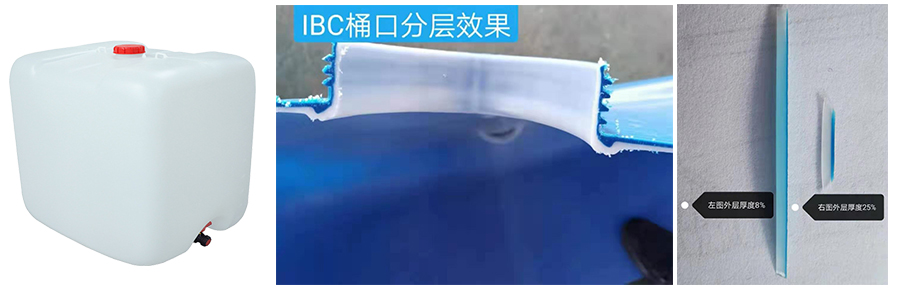

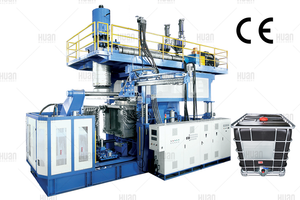

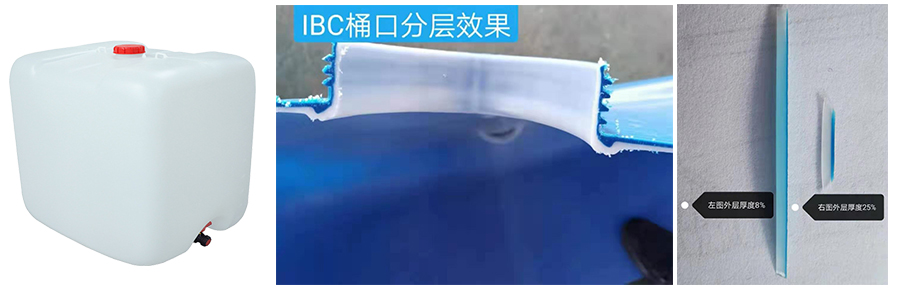

The IBC Tank Extrusion Blow Molding Machine produced by HUAN Machinery is for 500L to 1200L IBC tanks production. These IBC tanks are widely used across the chemical, filling, and transportation industries due to their ease of stacking, which reduces storage space and saves costs.

Key Features & Advantages for IBC Blow Molding Machine

German Technology: Precise and mechanical design with top-level German technology for excellent reliability and technology.

Continuous Production: The IBC tank blow molding machine can 365 days non-stop operation, ensuring a 24/7 output to meet client demand.

Experienced Cases: With the trust of our clients, we have supplied 188 IBC tank blow molding machines to both domestic and international markets.

High Output: Standard production of 600 tanks/day for a 14kg IBC inner tank, with a high-speed option of 864 tanks/day.

Technical Specifications for IBC Tank Blow Molding Machine

| Machine Model | BSM1000 |

| Product Capacity | 500L 800L 1000L 1200L IBC Tanks |

| Layer | 2 | 3 |

| Extruders | 120mm/120mm | 90mm/120mm/90mm |

| Main Drive | 110kw/110kw | 75kw/110kw/75kw |

| Max. Extrusion Output | 850kg/hr | 1050kg/hr |

| Clamping Force | 2000KN | 2000KN |

| Average Energy Consumption | 160kw | 170kw |

Operating System & Mold for IBC Tank Blow Molding Machine

Operating System: Equipped with MOOG's wall thickness control system, Gefran PLC, and a precision control system to ensure uniform tank wall thickness, reduce flash material, and save costs.

Mold: The IBC tank mold is made from high hardness aluminum material with an advanced cooling system, ensuring a high output rate of 25 tanks/hour.

Customer Show for IBC Machines

EU Client: "Can’t distinguish HUAN machine and European machine, considerate & top-level EBM."

USA Client: "Chinese technology is amazing, we have to try IBC tank blow molding machine."

EU Client: "We are so excited that we found European-level IBC blow molding machine with economic cost."

Turkish Client: "Really unbelievable, our engineer learned to operate the 1000L IBC tote blowing machine in just one day."

About HUAN Plastic Machinery

Total Solutions: We are a total solution provider for 25L, 200L, and 1000L IBC packaging projects.

Technology Focus: Our focus is on co-extrusion blow molding machines with German technology and zero-labor full automation.

Client Benefits: We help clients save on labor costs, achieve high-level output, and ensure stable, continuous operation for maximum profit.

For more information or to discuss your specific requirements, please contact us.