Germany technology Precise & Mechanical design IBC tote machine with top-level Germany technology for excellent reliability and technology. | 365 days non-stop Continuous production without break, ensuring 24 hours / 7 days output to satisfy final client’s order demand. |

188 experienced cases Thanks to trusting from our clients,we already supplied 188 IBC make lines to Chinese local and international markets. | High-level output 14kg ibc tank inner container Standard: 600 tanks/day High speed: 864 tanks/day |

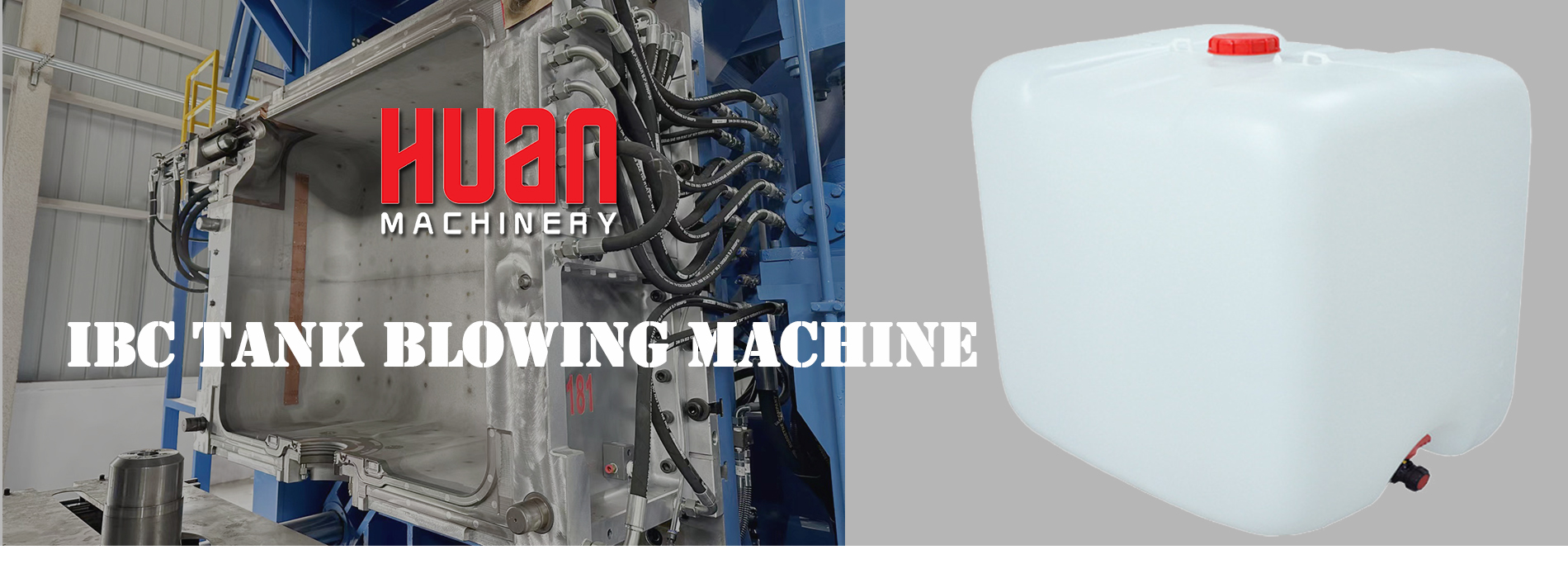

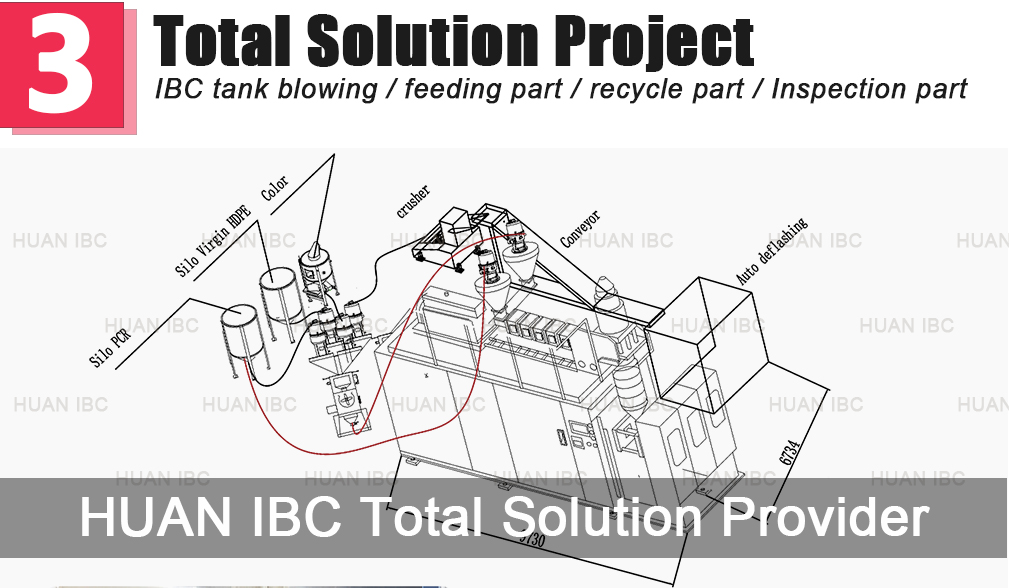

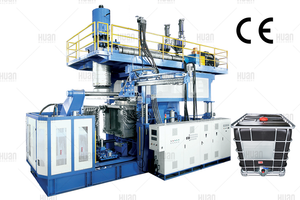

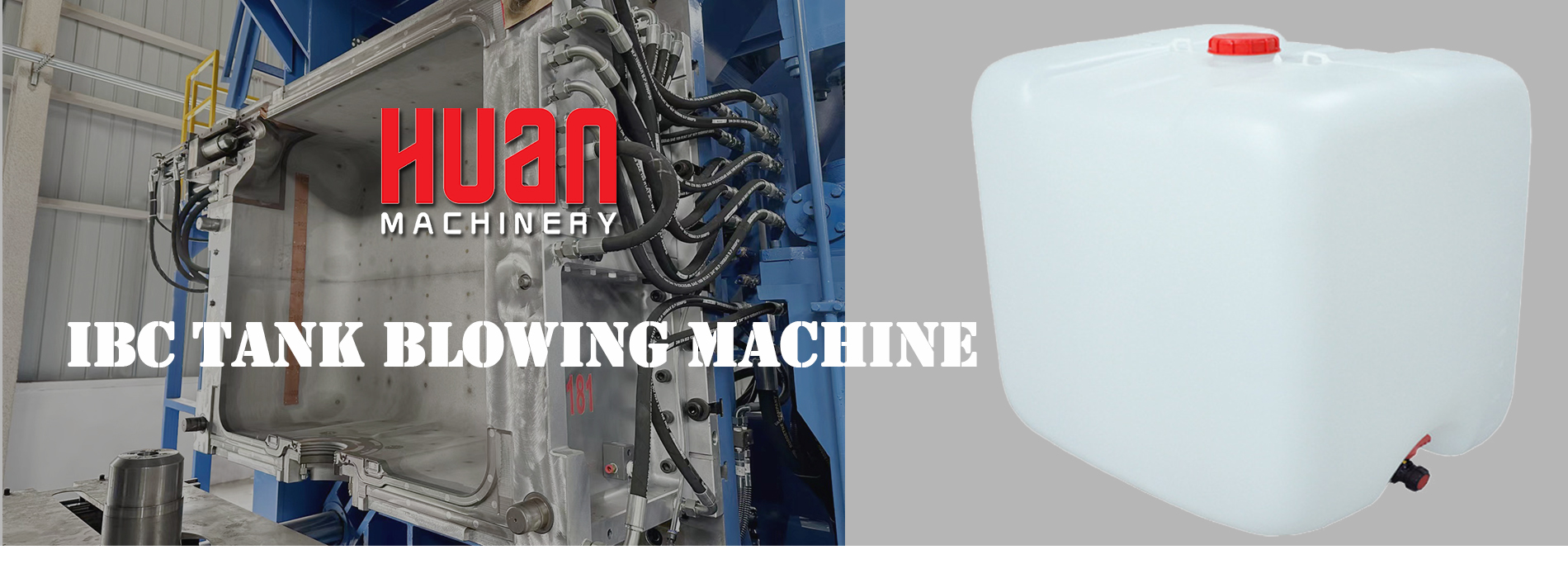

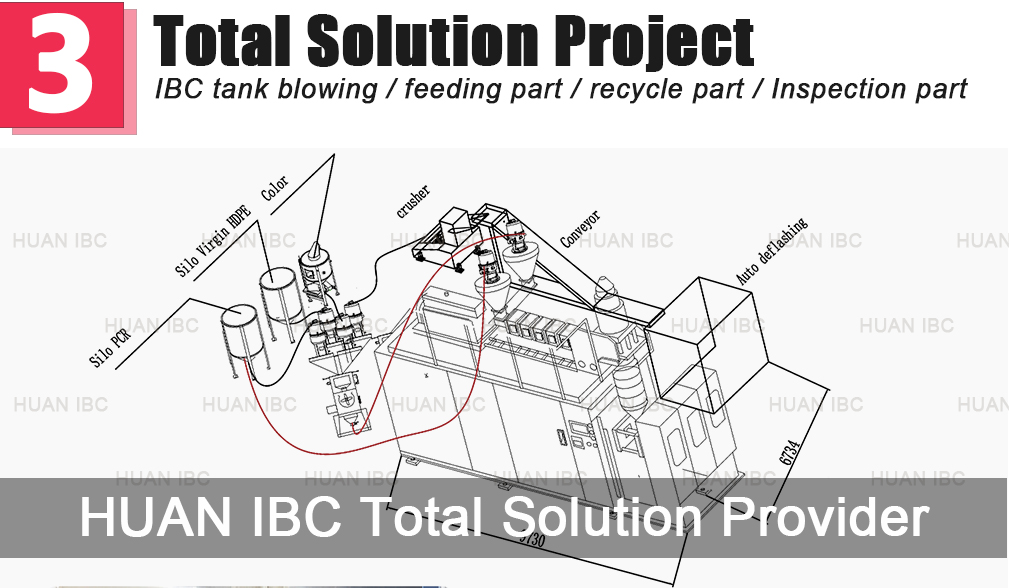

IBC tank blowing system

1000L IBC tank blowing which ensures uniform thichness and good performance for dropping test vibration test.

IBC tank valve connection 0-leakage

Operating system

Precision-engineered lBC tank blow molding mold ensures uniformwallthickness, smooth finishes, and highdurability for consistent.

IBC tank blow mold

Aluminum material with high hardness,advanced design cooling system which ensures high output 25 tanks/hour.

Machine Model | HUAN-IBC machine |

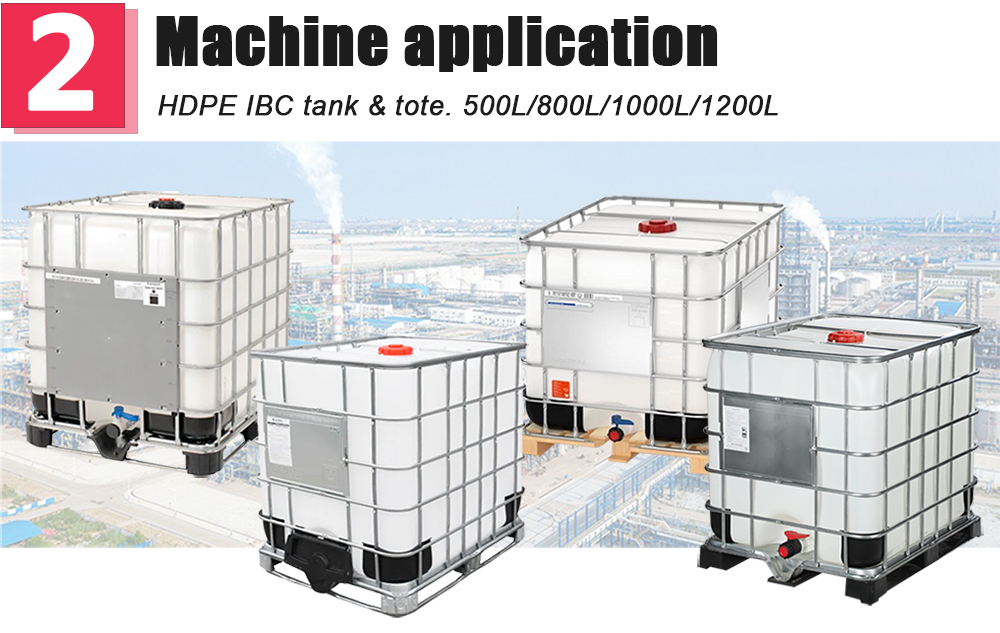

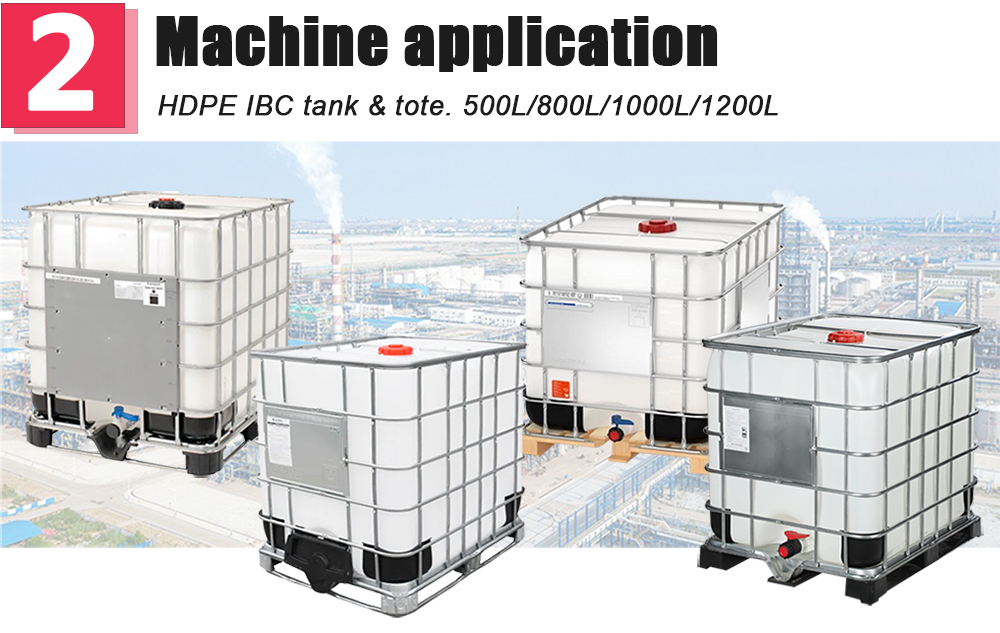

Prdouct Capacity | 500L,800L,1000L,1200L IBC |

Layers | 2 | 3 |

Extruders | 120mm/120mm | 90mm/120mm/90mm |

Main Drive | 110kw/110kw | 75kw/110kw/75kw |

Max. Extrusion Output | 850kg/hr | 1050kg/hr |

Clamping Force | 2000KN | 2000KN |

Average Energy Consumption | 160kw | 170kw |

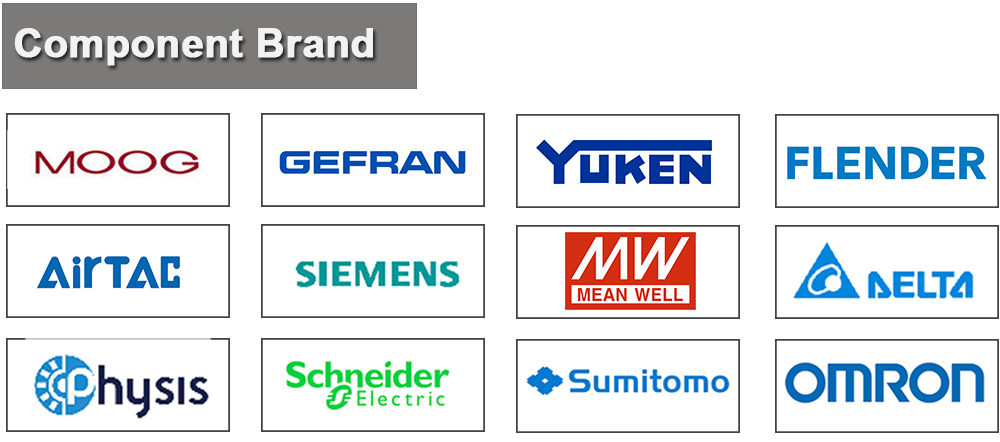

Italian GEFRAN: GEFRAN is known for its advanced control systems that ensure precise operation and seamless integration, thereby increasing the efficiency and productivity of the blow molding process on the IBC tank blowing machine.

IBC tank blowing machine is professional customized for the production of EU standard IBC tank,providing a total solution to worldwide customers.Our machine is designed with Multi-layer Coex by Germany technology and advanced mold,make top and safety IBC tank for various industrial package such as Chemical,food,agrochemical,automative liquids,which ensures safe transportation and loading.

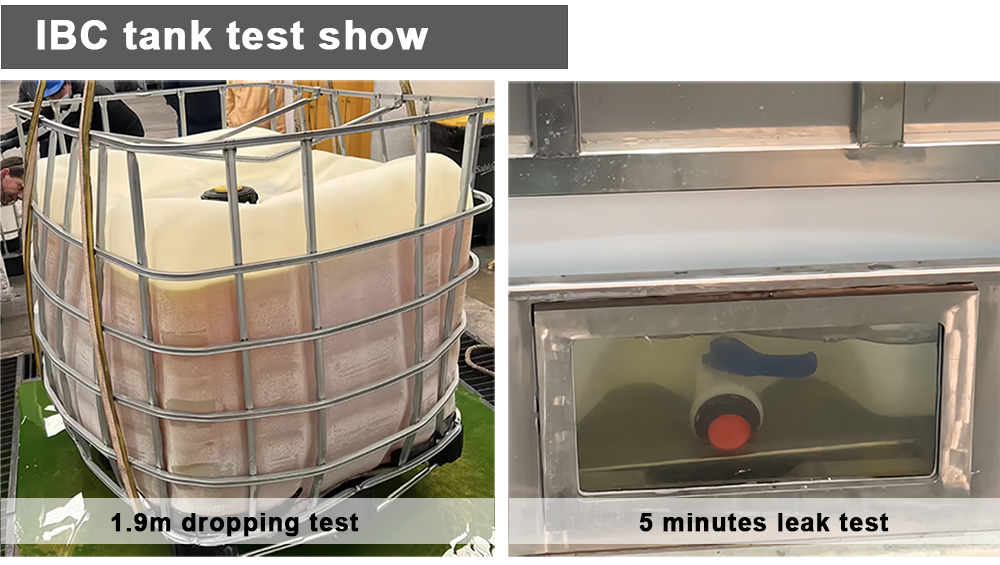

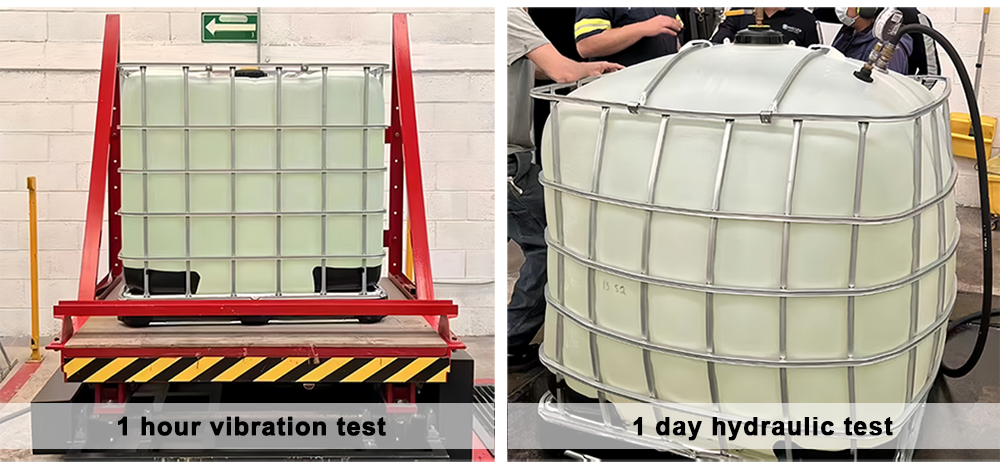

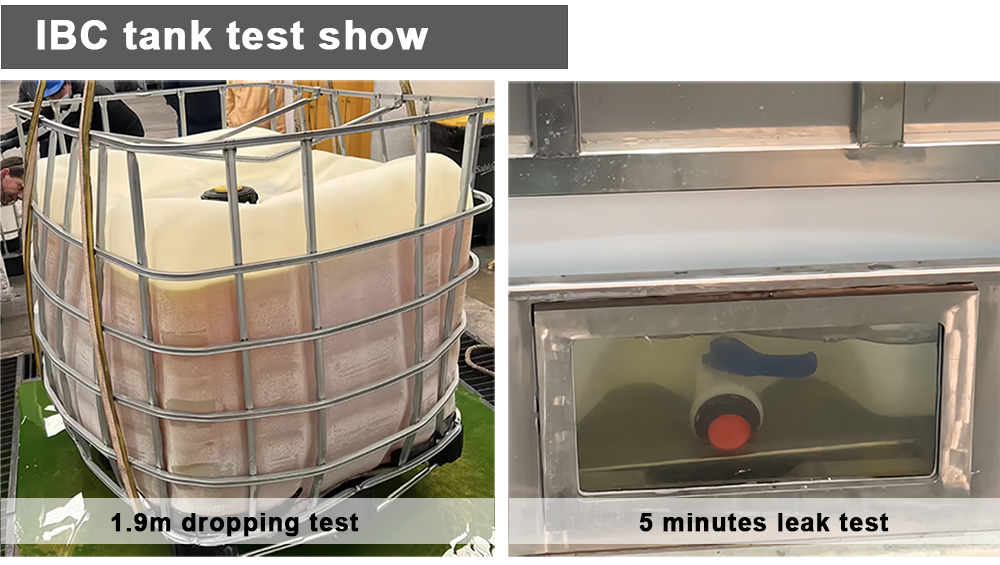

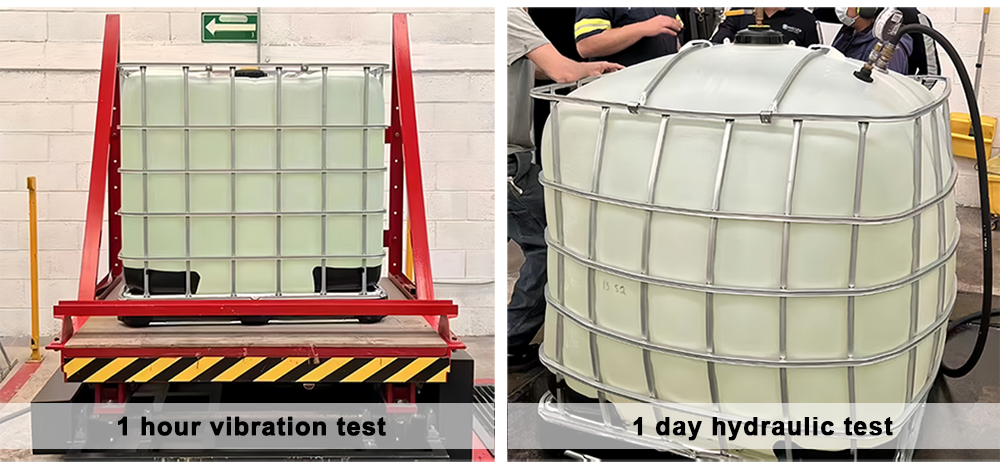

The IBC tote sample is tested by 1.9M dropping test after -18 degree frozen,0.8Mpa pressure leak test ,1 hour vibration testing and 1 day hydraulic test,all testings result are perfect with good performance.

IBC tank blowing

Through 15 years reaserch and design,our IBC tank machine meets European technology and we sucessfully supplied 188 sets IBC machines to all over the world.

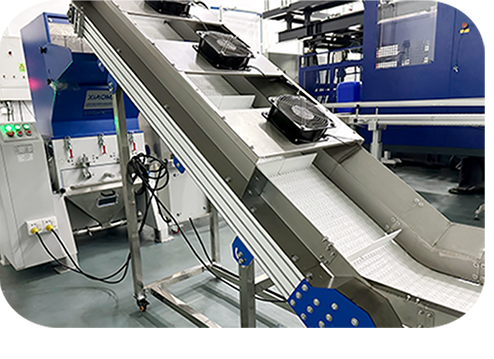

Feeding part

The production line adopts the proportional weighing machine, provide accurate materials ratio.

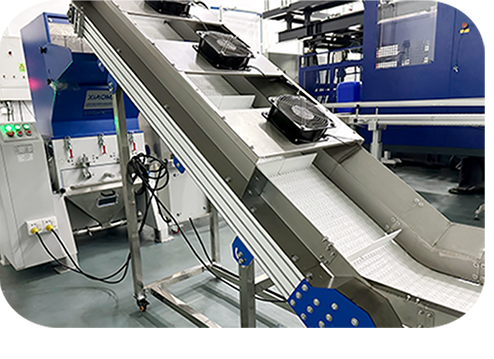

Recycling part

Good quality crusher and special conveyor with cooling, get the recycle material for reusing.

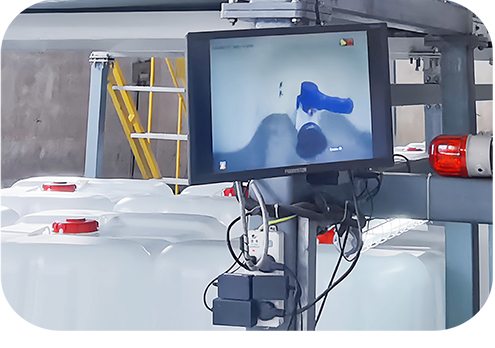

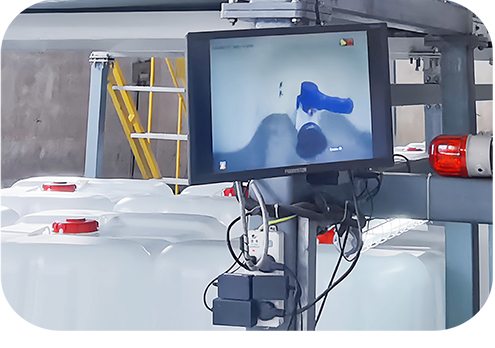

Inspection part

Leak part:Make sure offer NO-LEAK lBC tank for finaluser, we add leak testing process.

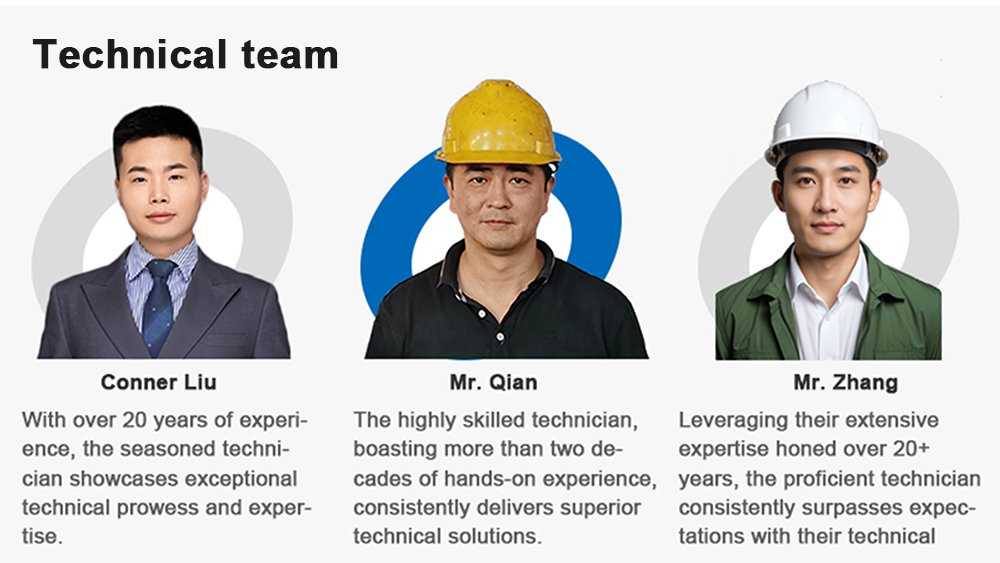

With over 20 years of technical expertise and work experience, our team of technicians, electric designers, and engineers at HUAN MACHINERY is unparalleled in China. Specializing in blow molding machines and IBC production lines, we are a leading provider of innovative solutions in the plastics manufacturing industry. Our commitment to quality, reliability, and customer satisfaction sets us apart from the competition. With a strong track record of success and a reputation for excellence, HUAN Machinery is your trusted partner for cutting-edge technology and top-notch service. Contact us today to discover how we can help take your business to the next level for ibc tank production.

Who are we?

Total solution provider for 25L, 200L and 1000L IBC package project.

What are we?

Coex blow molding machines with Germany technology and focus on zero-labor full automation blowing line.

Why are we?

Clients realize labor-cost saving, high-level output, stable-continuous running, make client's profit maximum.

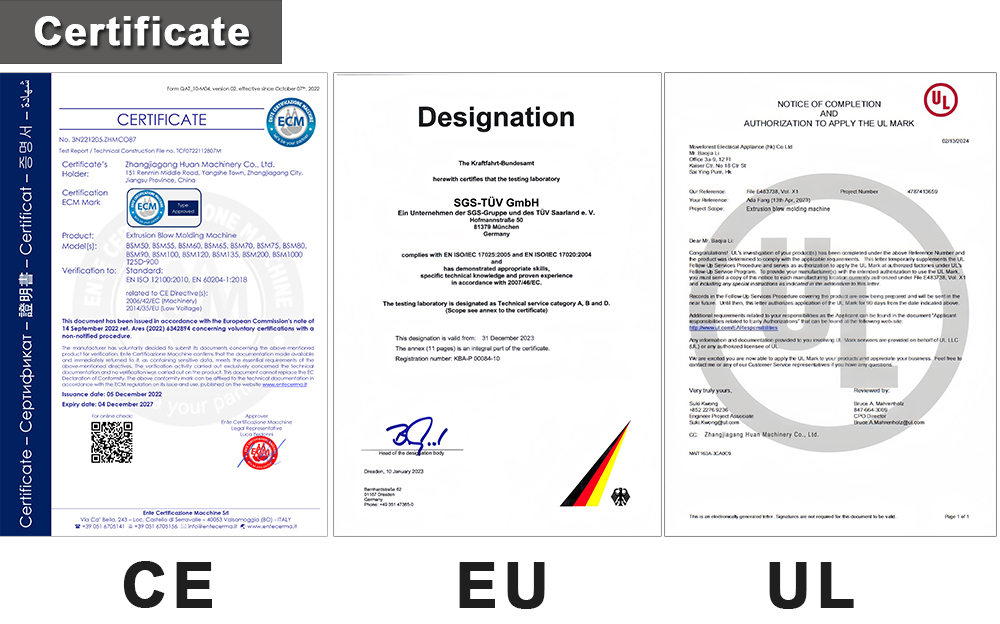

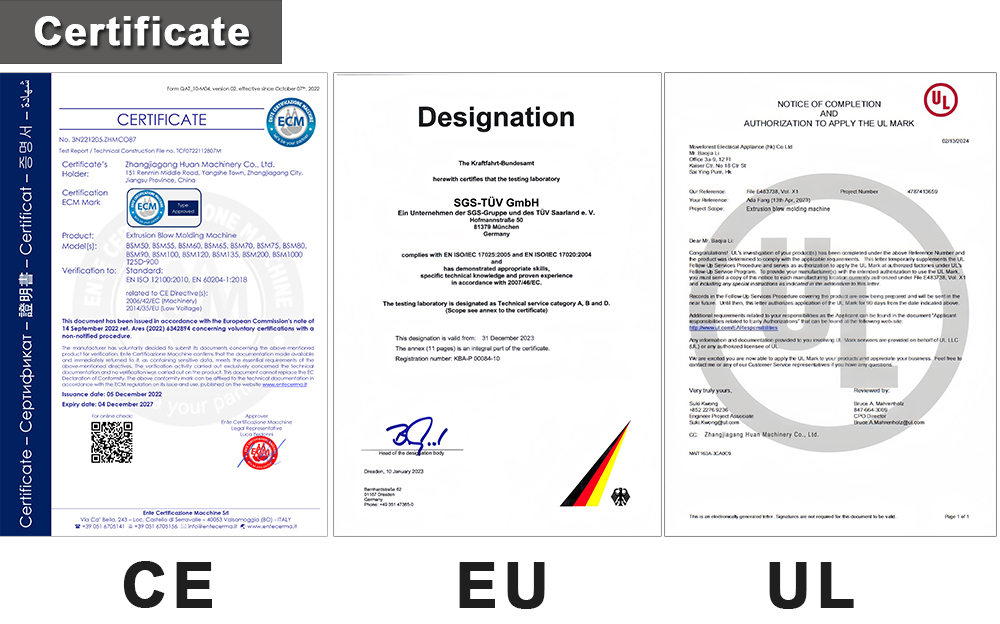

We sucessfully got CE certificate,EU certificate,UL certificate,which make HUAN company qualified to export IBC full production line to worldwide market.Warmly welcome you to jion into IBC family!

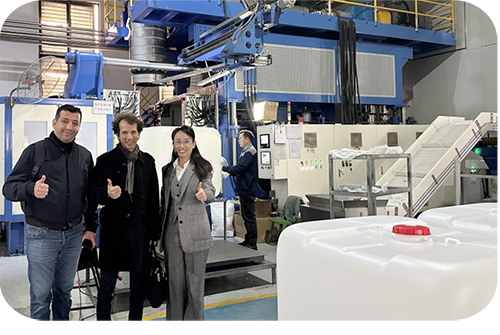

Client from EU country:

After viewing our IBC blow molding machine, they give commend: “ Can’t distinguish HUAN machine and European machine, considerate & top-level EBM” .

Clients from USA:

“Chinese technology is amazing, we have to try IBC tank blow molding machine”. They praised.

Client from EU country:

"We are so excited that we found European-level IBC blow molding machine with economic cost", they give comment.

Client from Turkey:

Client engineer spent 1 day learning our 1000L IBC tote blowing machine running which he never touched before. Really unbelievable.

The lBC blow molding machine is carefully packed for export, ensuring it arrives at the customer's handsin perfect condition. The packaging is secure, moisture-resistant, and sturdy, guaranteeing the machine's safety and integrity during transit.