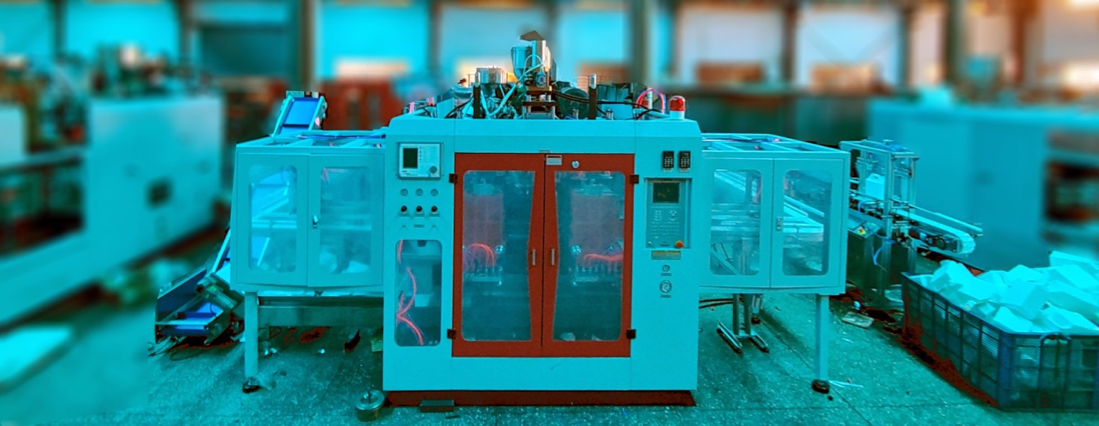

extrusion blow moulding machine

The articles shown below are all about the extrusion blow moulding machine, through these related articles, you can get relevant information, notes in use, or latest trends about the extrusion blow moulding machine. We hope these news will give you the help you need. And if these extrusion blow moulding machine articles can't solve your needs, you can contact us for relevant information.

- 2021-08-04When the hydraulic oil is in use, if the temperature is too high, the viscosity of the hydraulic oil will decrease, and the lubricity will decrease, which will accelerate the wear of the oil pump and hydraulic components during operation, which is likely to cause leakage. If the temperature is low,

- 2021-08-03Plastic chemical barrels are also called plastic chemical barrels. They are blow-molded using scientific formulas. They have diverse colors and beautiful appearance. They are resistant to acid and alkali, corrosion, leakage, non-fading, and non-deformation. Ideal for long-distance transportation of

- 2021-07-31Blow-molded product deformation means that its external shape deviates from the shape of the mold cavity, or convex or concave, or longitudinal or radial, or partial shape deviation. It is one of the common defects of blow molding products, and it is also one of the most comprehensive and difficult

- 2021-07-26It is well known that multi-layer co-extrusion technology is currently widely used in food, cosmetics, agrochemical packaging and other industries. Today we introduce various applications in detail, as follows:

- 2021-07-14Plastic extrusion blow molding machine has the advantages of high speed and stable operation. In recent years, it has become one of the main equipment in the production of industrial products. So what is the working principle of the plastic blow molding machine that is so popular among customer manufacturers?

- 2021-07-01Extrusion blow molding is used in large-scale hollow blow molding. For large products, there are two key molding technologies. 1. It is required to quickly provide the amount of melt required for the product, and reduce the drop and caliber of the parison caused by the large volume and dead weight; 2. The cooling of large products can be long, and the extruder cannot be continuously performed, so the head with a storage cylinder is developed. Hollow blister products with a volume exceeding 20L are called large hollow blow molded containers.