- Home

- About Us

- 25L Blow Molding Machine

- 200L-220L Drum Blowing

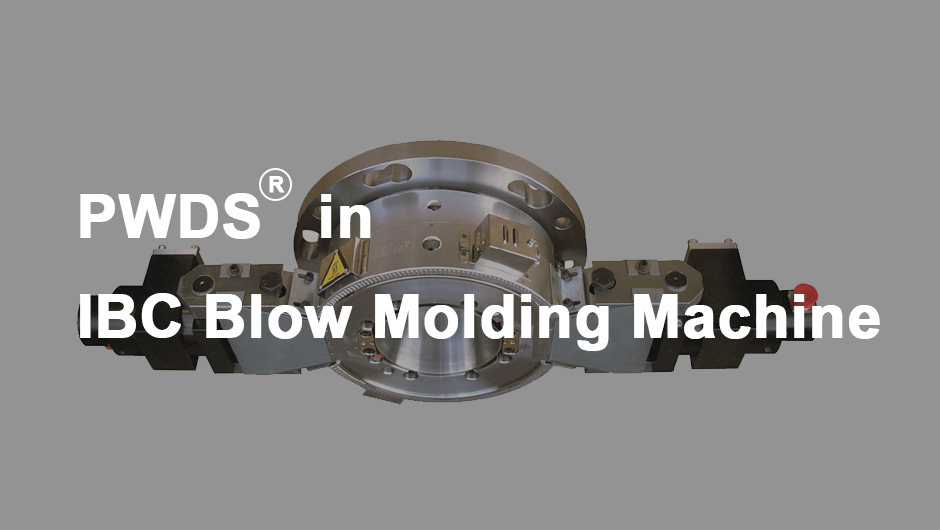

- IBC tank production line

- Plastic Machinery

- Chemical Drum Blow Molding Machine

- Daily Chemical bottle Blow Molding Machine

- Agrochemical Bottle Blow Molding Machine

- Food Industry Bottle Blow Molding Machine

- Engine oil bottle blow molding machine

- Child toy blow molding machine

- Blow Molding Machine for Others

- Garden Can Blow Molding Machine

- Toy Blow Molding Machine

- Floationg Dock Blow Molding Machine

- Traffic Block Blow Molding Machine

- Medical Product Blow Molding Machine

- Auto Motor Blow Molding Machine

- Isulation Container Blow Molding Machine

- Body Manikin Blow Molding Machine

- Hollow Board Blow Molding Machine

- Hollow Seat Blow Molding Machine

- Hollow Pallet Blow Molding Machine

- Automatic auxiliary machine

- Injection Molding Machine

- PET bottle blow molding machine

- Contact Us

English

English