Automatic Asphalt Bag Pallet Frame Welding Machine | 500 Frames/Day

Asphalt Packaging Iron Frame Welding Machine – Product Introduction

The Asphalt Packaging Iron Frame Welding Machine is a high-efficiency, precision-engineered solution designed for the automated welding of iron frames used in asphalt packaging. Built for durability and performance, this machine ensures strong, consistent welds, enhancing productivity and reducing manual labor in industrial packaging operations.

Key Feature

✔ High-Speed Welding – Delivers fast, accurate welds for improved production efficiency.

✔ Robust Construction – Heavy-duty design ensures long-lasting performance in demanding environments.

✔ User-Friendly Operation – Intuitive controls and adjustable settings for seamless integration into production lines.

✔ Precision Welding – Ensures uniform weld quality for sturdy and reliable iron frames.

✔ Low Maintenance – Engineered for minimal downtime, reducing operational costs.

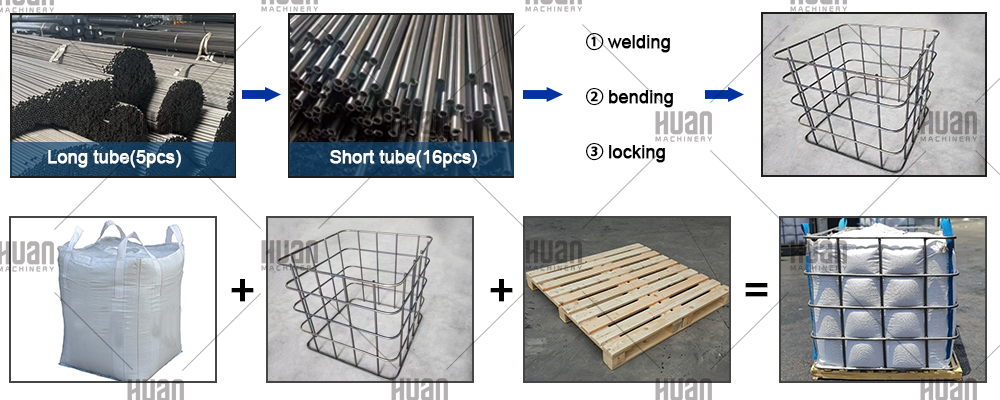

Production and Application Workflow |

From Raw Material to Ready-to-Fill Asphalt Packaging: A Seamless 5-Step Process

Here is how our welding system transforms steel bars into secure, logistics-ready packaging for asphalt.

Step 1: Automated Mesh Welding

Our welding machine automatically positions 5 horizontal and 16 vertical steel bars.

It then performs high-strength MIG welds at every intersection, creating a single, rigid reinforced mesh panel.

Step 2: Bending & Forming

The welded mesh panel is automatically transferred to a hydraulic press brake.

In one motion, the four sides are precisely bent upwards and the ends are formed into interlocking locking brackets, creating a complete steel frame.

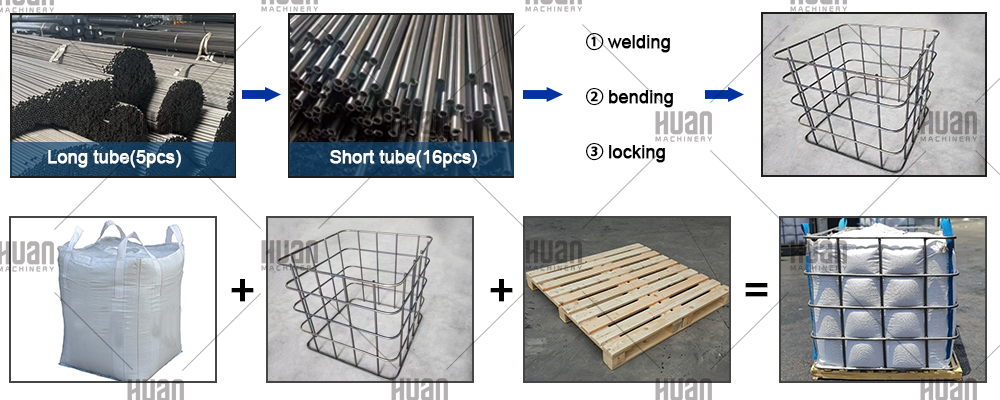

Step 3: Assembly with Wooden Pallet

The formed steel frame is placed onto a standard wooden pallet.

Workers use power tools to quickly fasten the frame to the pallet through pre-designed holes with high-tensile screws, ensuring a solid unit.

Step 4: Bag Insertion

Step 5: Asphalt Filling

| SPECIFICATION | DESCRIPTION |

| Rated Power | 250kva*4 |

| Electrical Requirement | 3P 380V; 350KVA with 400A Air Switch, 70mm2 Copper Cable |

| Duty Cycle | 0.5 |

| Control Method | PLC |

| Frequency | 1000Hz |

| Welding Size | 1200mm*4250mm |

| Max.Output Voltage | DC11V |

| Material | Galvanized tube with ribs, thickness 1-2mm; dia: 14-20mm |

| 8-hour production | 300-400 grids |

| Insulation Grade | F |

| Air Supply | 0.4-0.6Mpa |

| Cooling Water | 6L/min 5 degree less than room temp. |

Application

Asphalt Production Plants: For packaging finished products like petroleum asphalt, modified asphalt, and colored asphalt.

Construction Material Logistics Centers: Provides high-volume frame production for third-party packaging services.

Major Infrastructure Projects: Supports large-scale asphalt mixing plants for highway, airport, and dam construction projects.