Advanced Welding Technology for Automotive Manufacturing

Our professional auto parts welding systems deliver exceptional precision, strength, and consistency for all your atechnical specificationutomotive production needs. Engineered for the rigorous demands of modern vehicle manufacturing, our welding solutions ensure superior quality for engine components, exhaust systems, structural body parts, and suspension components.

Industry-Leading Precision: Robotic welding arms with ±0.05mm repeatability ensure consistent, high-quality welds on all auto parts

Reduced Operational Costs: Advanced pulse technology minimizes spatter and energy consumption, lowering your cost per weld

Enhanced Productivity: High-speed welding capabilities with integrated quality control reduce production time

Multi-Material Compatibility: Effectively weld various automotive materials including steel, aluminum, and advanced alloys

Compliance Ready: Meets international automotive standards including ISO 3834, AWS D1.1, and IATF 16949 requirements

Technical Specification: Auto Parts Welding System

Key Specifications | AutoTrace Pro | Industry Average |

Traceability Accuracy | ±0.05mm | ±0.1-0.2mm |

MES Integration Speed | < 0.5 seconds | 2-5 seconds |

|

Electrode Material | Chromium-Zirconium Copper (CuCrZr) | Standard Copper |

IP Rating | IP54 (Dust/Water Resistant) | IP20 |

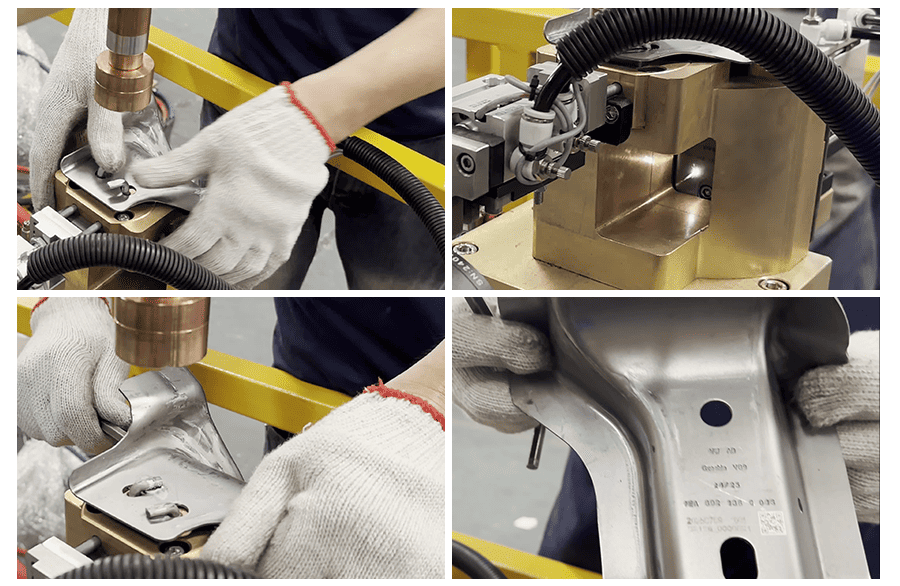

Automotive Welding Applications

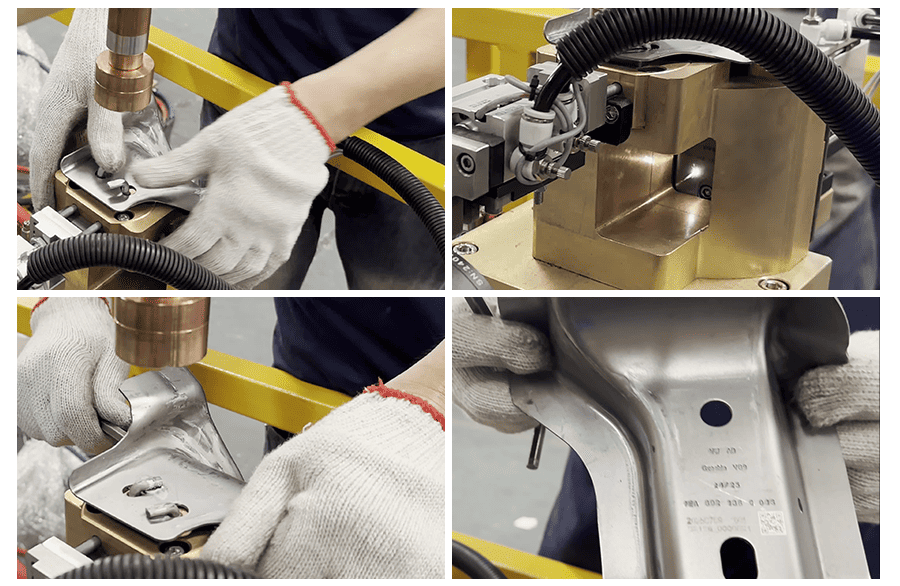

1. Exhaust Systems Welding: Precision TIG-like welding on thin exhaust materials

2. Body-in-White Assembly: High-strength structural welding for vehicle frames

3. Suspension Components: Multi-pass welding on critical safety components

Our auto parts welding equipment is ideal for:

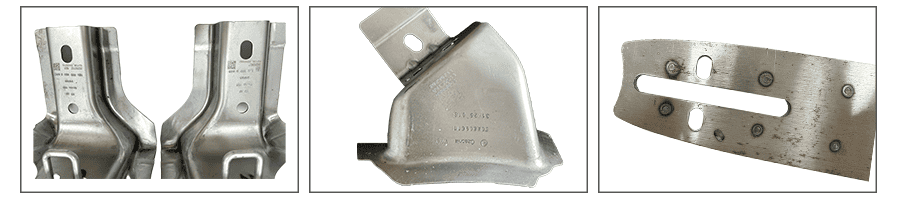

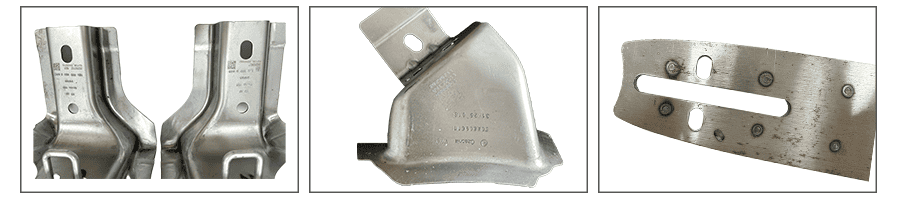

Chassis and structural component welding

Exhaust system manufacturing and repair

Engine component assembly

Suspension and brake system fabrication

Body panel joining and repair

Why Choose Our Automotive Welding Solutions?

Proven Automotive Expertise: Over 15 years specializing in auto parts welding solutions

Comprehensive Support: Installation, training, and maintenance programs tailored to automotive clients

Quality Assurance: Every system undergoes rigorous testing before shipment

Customization Options: Configurable solutions for your specific production requirements

Electric vehicle battery tray assembly