30L Blow Moulding Machine Description:

High speed multi-layer 25L extrusion blow molding machine for 20L to 50L hdpe jerry can,plastic drums.Single layer ,2 layers,3 layers optional,high productivity 1,330 pcs per day.

Fully automatic jerry cans blow moulding production line, including auto de-flashing, waste material and final bottles delivery, valid connection to other auxiliary equipment.

30L Blow Moulding Machine Technical Parameter:

| Specification | BSM80N-30L |

| Max product volume (L) | 30 |

| Machine weight (T) | 13 |

| Machine size(m) | 4.8X2.6X3.8 |

| Extrusion unit |

|

| Screw diameter (mm) | 80 |

| Length/Diameter ratio | 24/1 |

| Heating zone No. (pcs) | 4 |

| Heating power (kw) | 20.2 |

| Cooling fan No. (pcs) | 4 |

| Fan power (kw) | 0.52 |

| Extrusion motor power (kw) | 30 |

| Plasticizing capacity (kg/h) | 125 |

| Die head |

|

| Head type | accumulating |

| Accumulating volume (L) | 5 |

| Max ejection weight (kg) | 4 |

| Heating Zone No. (pcs) | 4 |

| Heating power (kw) | 15.2 |

| Max die diameter (mm) | 250 |

| Clamping unit |

|

| Clamping force (KN) | 230 |

| Platen size (mm) | 850*900 |

| Platen opening stroke (mm) | 400-900 |

| Max mould size (mm) | 600*1050 |

| Mould thickness (mm) | 450-510 |

| Total power (kw) | 92 |

| Average energy consumption (kw) | 30 |

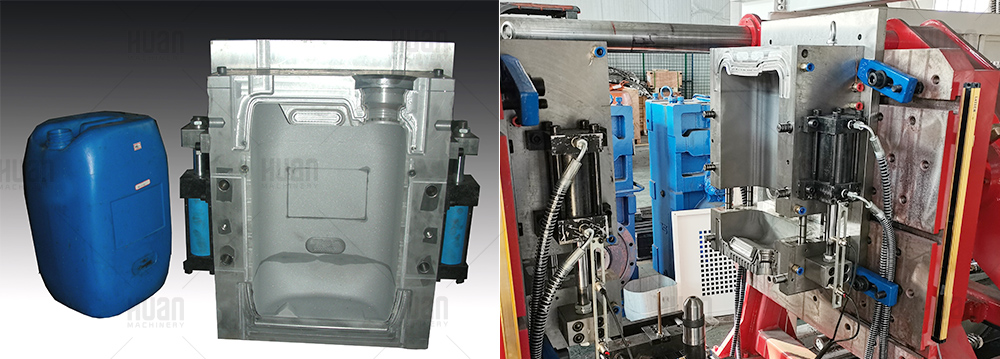

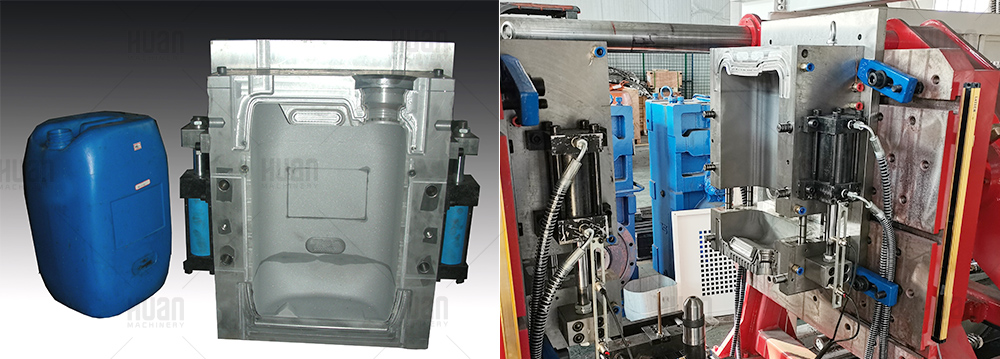

30L blow machine clamping structure

The blow molding machine is plate structure.Its action is with linear guide rail, sliding block, pull rod, proximity switch and transducer to make the movement smoothly and position precision.

Read More

30L blow machine extrusion system

The screws can be 2 screws,3 screws optional,high strength screw and cast aluminum heater heat the plastic material evenly.

Read More

30L blow machine die head

Central feed die head – continuous type, the parison ejected out quickly and change the material easily.Better control of the uniform wall thickness.

Read More

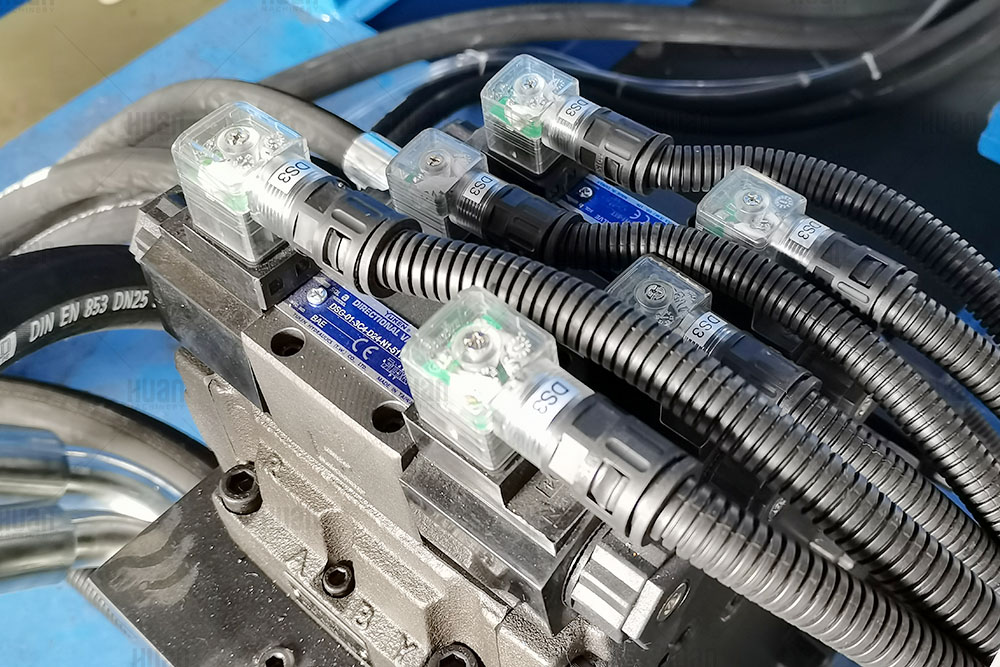

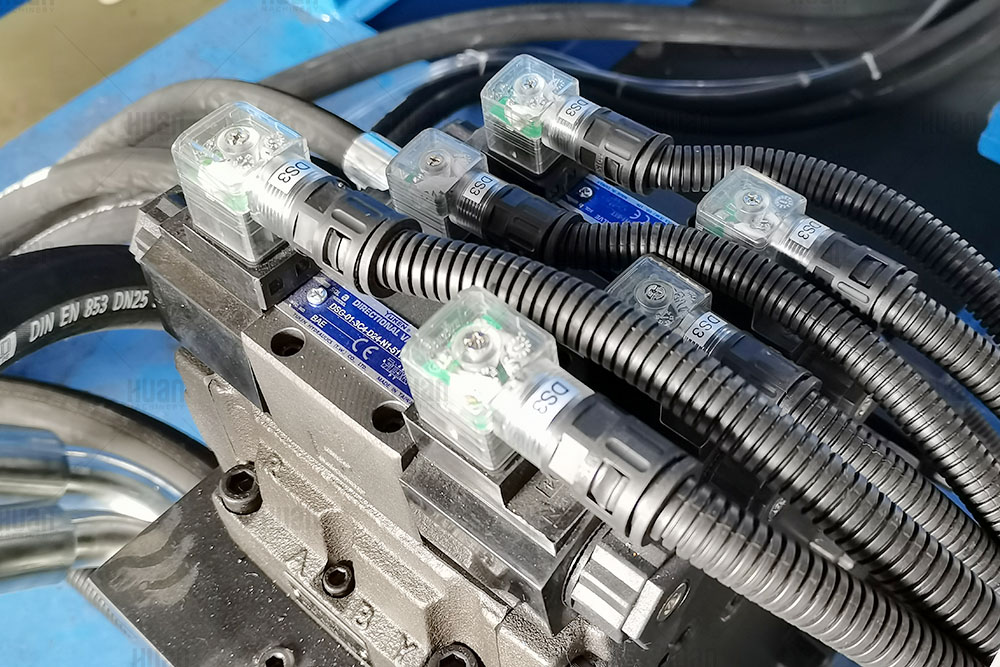

30L machine hydraulic system

Adopt famous brand components, like YUKEN valve and pump, SIMENS BEDE motor, valve block and so on.This system controls all actions of the machine. machine.

Read More

30L Blow Molding Machine Application: