In the realm of modern industry, the propulsion of innovative technologies not only enhances manufacturing efficiency but also redefines production standards. Amid this dynamic landscape, the IBC tank blow molding technology stands as a trailblazer, steering the future of IBC tank production with its impactful influence. As a pivotal manufacturing process, IBC tank blow molding not only streamlines production lines but also ensures unparalleled consistency in product quality. Within this article, we delve into the core elements of IBC tank blow molding and its pivotal role within contemporary production lines. Let's unveil the enigma of this technology, exploring how it spearheads trends in the manufacturing sector and reshapes the trajectory of product innovation.

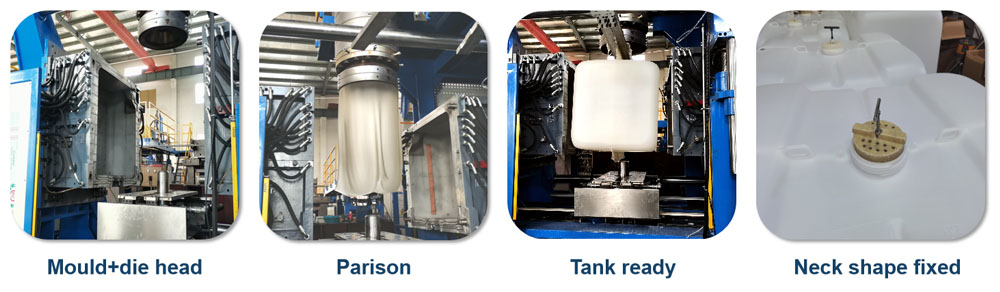

Introducing the IBC tank blow molding machine line — a synergy of technological prowess and precision engineering. This integrated system comprises key elements such as the extrusion blow molding machine, IBC tank mold, and quality testers, seamlessly shaping high-quality IBC tanks with efficiency and reliability. This line redefines manufacturing, ensuring top-notch products that meet the highest industry standards.

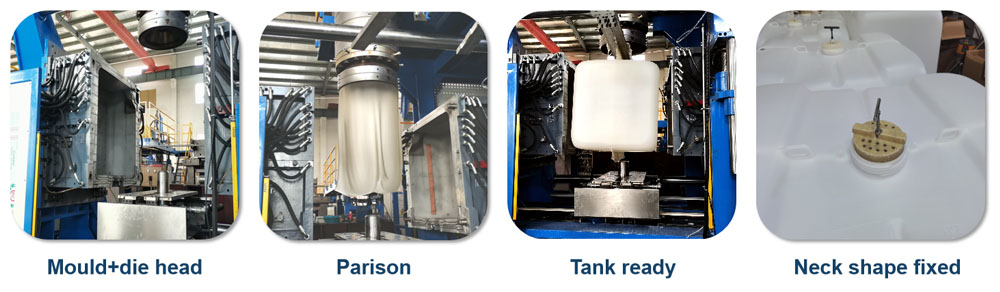

IBC tank blowing machine in production

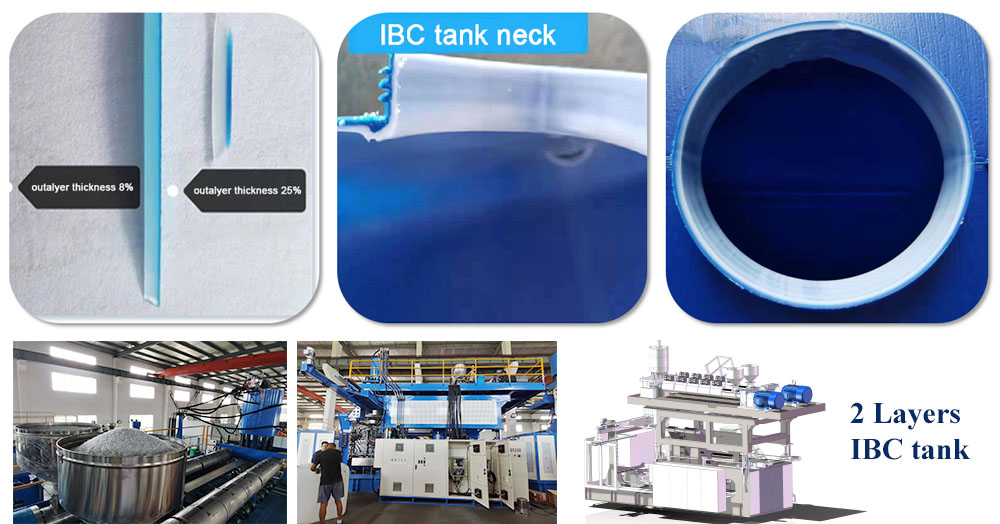

The IBC tank blow molding machine offers versatile options with single layer, 2-layer, and 3-layer capabilities. With a production capacity of 22pcs per hour, this advanced system delivers efficiency and quality. Specifically focusing on the 2-layer IBC tank blow molding machine, it exemplifies precision engineering for optimal layering, ensuring robustness and fluid containment.

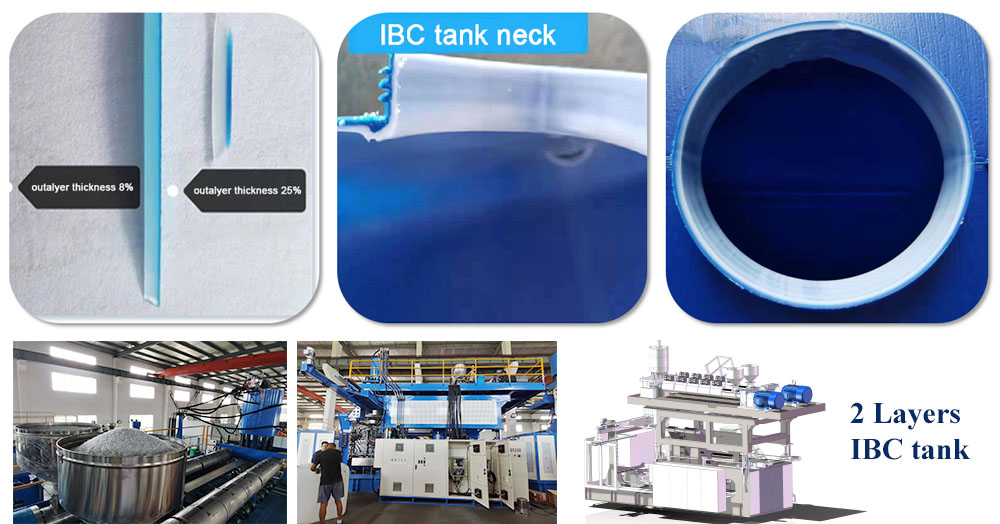

Enhanced Dual-Layer Capability:

1. Ensure liquid integrity with a light-proof outer layer in blue or black, safeguarding contents.

2. Utilize recycled HDPE for the outer layer, optimizing cost-efficiency without compromising quality.

3. Tailor the ratio rate of the dual layers, allowing flexible customization to meet specific requirements.

IBC tank blowing machine component list & specification sheet

SPECIFICATION | BMS135Z | DESCRIPTION |

Max Product Volume | 1000L IBM drum |

|

Machine Weight | 60Tons |

|

Machine Size(LxWxH) | 9.0×6.5×7.8(L×W×H ) |

|

EXTRUSION UNIT |

Screw Diameter | 120mmx 2 | For HDPE screw material |

Length/Diameter Ratio | 30:1 |

|

Barrel material |

| 38CrMoAIA + Nitride treatment |

Heater material |

| Ceramic + Melt sensor indiction |

Extrusion Motor Power | 132KWx 2 |

|

Plasticizing Capacity | 800Kg/hour | HDPE |

DIE HEAD |

Head Type | IBC drum special accumulating | First in first out |

Heating Zone No. | 8 |

|

Heating Power | 56KW |

|

Max Die Diameter | 950mm |

|

CLAMPING UNIT |

Clamping structure |

| Two tie bar |

Clamping Force | 2000 KN |

|

Platen Size | 1600*1600mm |

|

Platen Opening Stroke | 1200-2600mm |

|

Carriage movement |

| Linear guide+ slider high pressure cylinder |

CONTROL SYSTEM |

PARISON system | Have | Moog 100 point |

Touch screen | WEINVIEW | Made in Taiwan |

Robot arm | Have | Scissor type |

OTHERS |

Hydraulic motor | Servo motor | Italy PHASE |

Hydraulic pump | Servo pump | Japan SUMITOMO |

Extrusion Motor Power | 136KW*2 |

|

Total Power | 580KW |

|

Average Energy Consumption | 174KW |

|

Name | Supplier |

Hydraulic Servo Motor | PHASE/ Italy |

Oil Pump | SUMITOMO/ JAPAN |

Hydraulic Valve | YUKEN/ JAPAN |

Servo Valve | ATOS/ Italy |

Parison control system | MOOG/JAPAN |

Sealer | Top DZ / EUROPEAN |

Microcomputer Control System | MITSUBISHI PLC / JAPAN |

Touch Screen | WEINVIEW / JAPAN |

Temperature Controller | MITSUBISHI, / JAPAN |

SSR | OMRON / JAPAN |

Air Switch | SCHNEIDER/ GERMANY |

Motor | SIMENS BEIDE |

Power Resource | MEAN WELL/ TAIWAN |

Inverter | DELTA/TAIWAN |

1. This machine is used for producing plastic inner tank. Production capacity reaches 22pcs per hour

2. The machine adopts two extruder system and strong macromolecule screw, make sure the stable plasticizing capacity.

3. Special designed die core, could make min. weight 13kg IBC drum

4. Machine structure stable, middle plate through pull rod, whole frame with high precision module design, easily dismantle and assemble, finish assemble within one day

5. Drum thickness uniform, eight corners strong.

6. Stable hydraulic system, quick speed, injection material time about 10 seconds.

7. Special designed IBC accumulate head, exchange material quickly, low power consumption

8. Separate cooling system for screw cooling and hydraulic cooling to reach good cooling effect

9. Proportion valves for controlling bottom blow pin action and robot arm, precision and stable

10. Whole machine with European design.

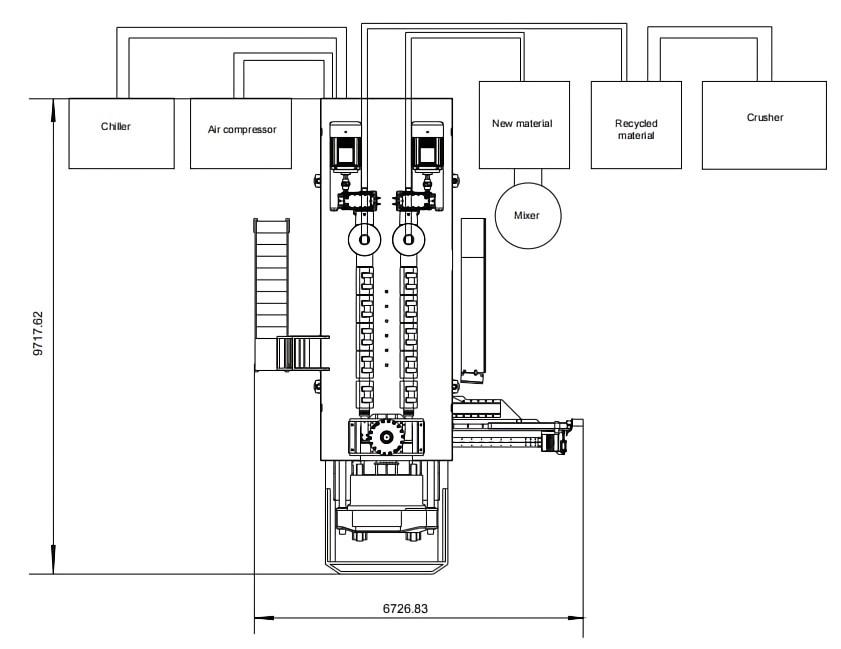

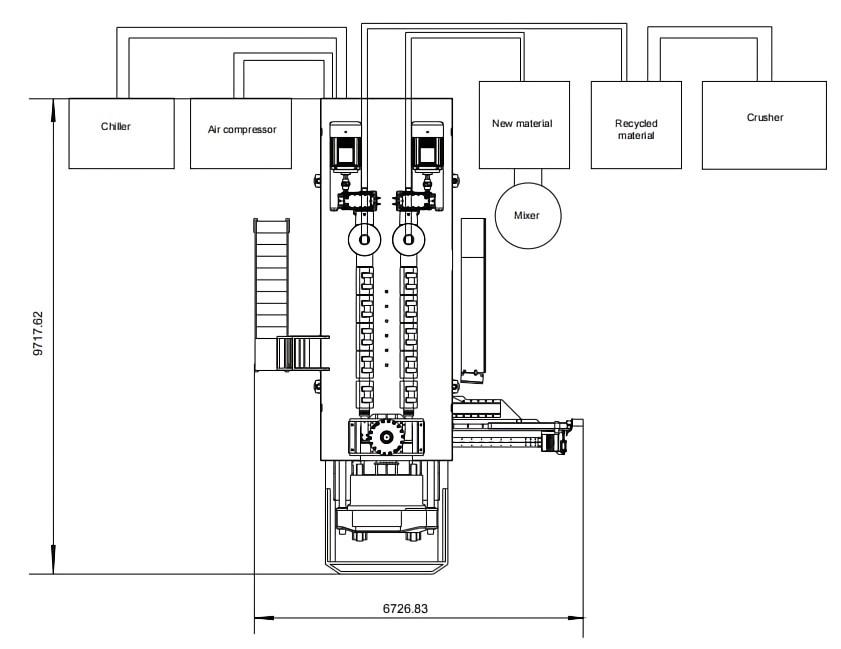

IBC tank blowing part layout

Auxiliary machines

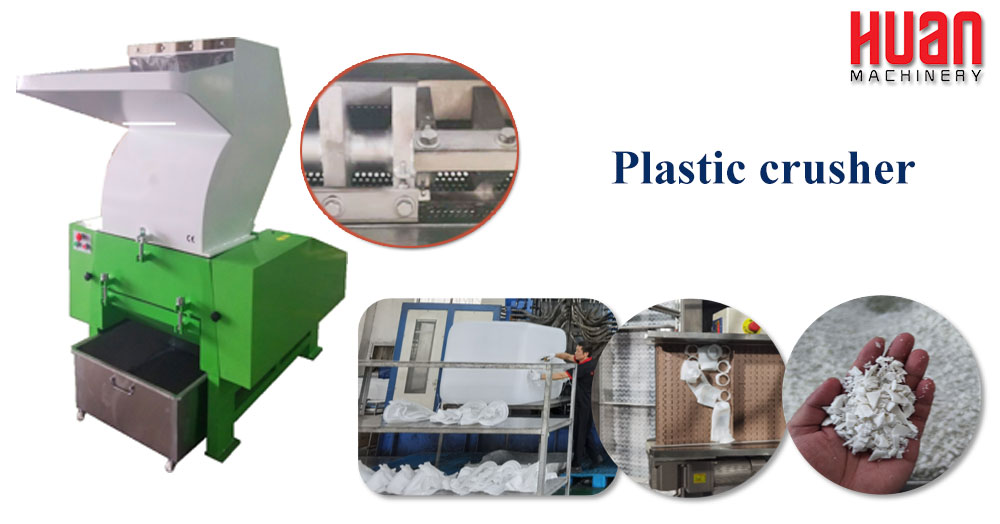

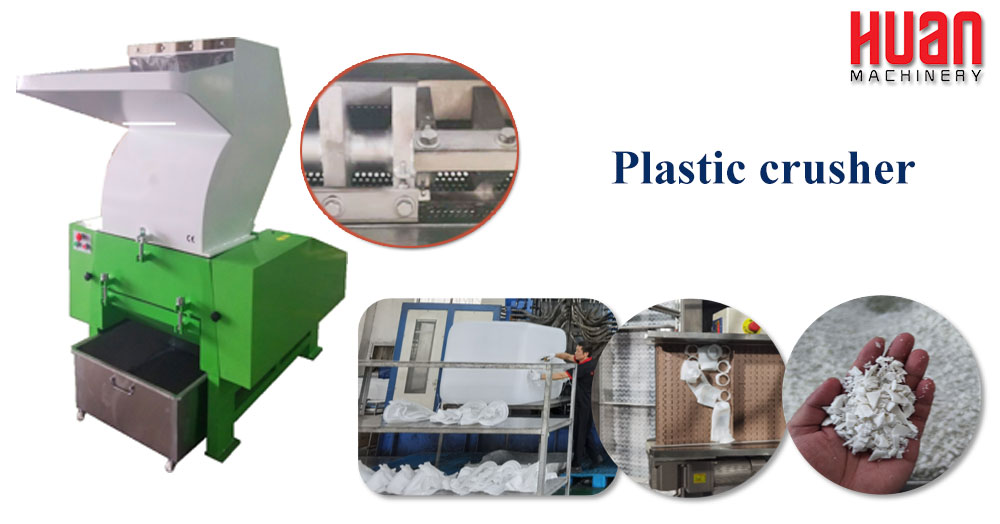

I. Plastic crusher

The plastic crusher machine is a device designed to convert plastic materials into smaller fragments. Its purpose is to recycle aged plastic goods and convert them into usable raw materials.

l All steel welded frame, durable

l Easy to remove design, easy cleaning, and maintenance

l Imported steel cutter, sharp blade, easy to replace, durable

l Crush all kinds of soft and hard plastic easily

l Equipped with motor overrun and electric chain ,protection system to ensure safe use

l Choices of different blades and screen mesh

Model | Power | Blade Nos. | Crushing chamber | Capacity | Size | Weight |

PD800 | 30Hp | 6+4 pcs | 815*470mm | 600kgs | 1750*1540*2340mm | 2T |

II. Vacuum auto-loader for feeding HDPE

The vacuum auto-loader is a device that uses suction to automatically transport and feed HDPE (High-Density Polyethylene) material into a processing or manufacturing system.

• Simple operation, easy maintenance, automatic electric operation program

• Stainless steel hopper

• Motor protector

• Automatic alarm for overload and lack of material

• Independent filter for easy cleaning

• Optional electric eye detection directly when installing machine hopper

Model | Power | Lift | Pipe D | Capacity | Size | Weight |

X800G | 1.5kg | 5M | 38mm | 600kgs | 1500*400*720mm | 80KG |

III.Mixer for HDPE raw material

Plastic mixer utilizes a swiftly rotating screw to lift raw material from the barrel's bottom to its center and then to the top, subsequently collecting and redistributing the dispersed material back to the bottom. This cyclical process efficiently achieves a thorough and uniform mixture of a substantial volume of raw materials within a short duration.

•Spiral cycle stirring, blending of raw materials more evenly and quickly

• Mixed strength, short time,low energy, high efficiency

• Equipment and raw materials contact part of the material are all stainless steel production, cleaning easy to avoid corrosion

• Timer can choose, mixing time 0-30 minutes

• Equipped with electric control safety protection devices to ensure safe operation

Model | Power | Speed | Heating Optional | Capacity | Size | Weight |

JB1000L | 4kw | 330r/min | 15kw | 1000kgs | 1300*2670*630mm | 700kg |

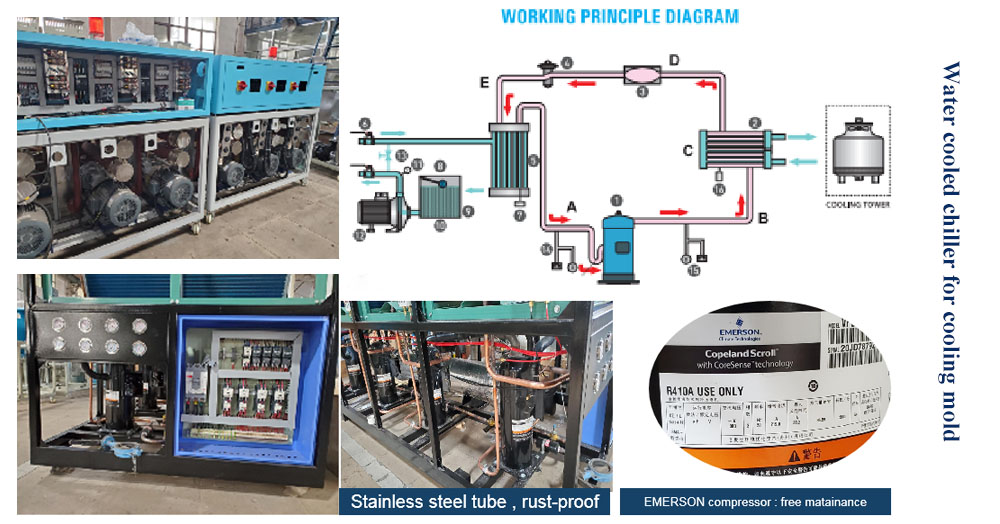

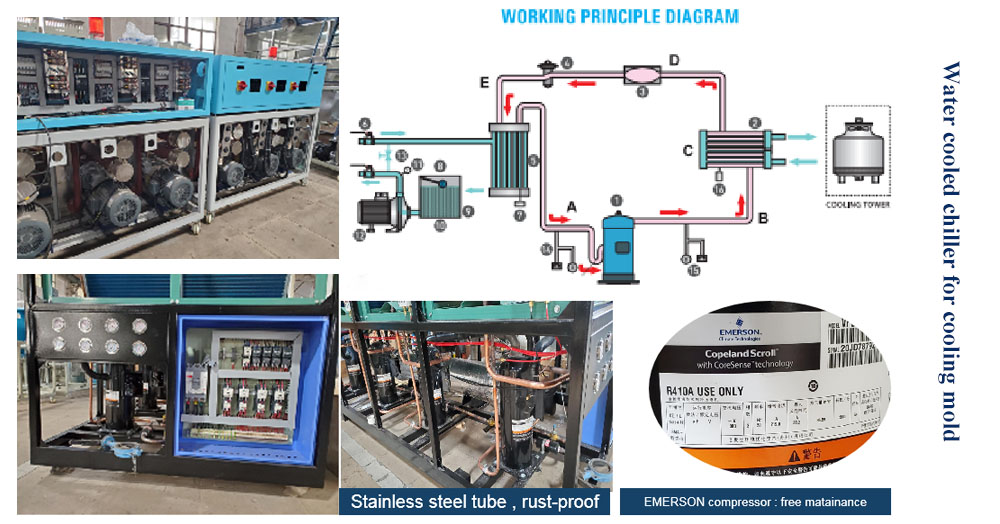

IV. Water cooled chiller

Water-cooled chiller is a cooling system that utilizes water as a medium to dissipate heat from a process or equipment, effectively lowering the temperature and maintaining optimal operating conditions.

1. with imported compress, high efficiency and strong ability of cooling

2. with compact size

3. with energy saving

4. most suitable for IBC tank cooling with perfect cooling and performing

Model | Power | Temperature of cooling water | Water flow | Capacity | Size | Weight |

SML-11S | 30Hp | 5-30 degree | 28cbm/h | 76000kcal per hour | 2800*900*1800mm | 1.2T |

V. Cooling tower for water chiller

1. Full sealed, anti-rainning, rotate speed average, anti-wearing, ABB brand motor

2. special designed reducer with long life

3. with aluminum-alloy material motor with high fans and low noise

4. Filling material:Virgin PVC forming, prolong time of water-air exchange, with longer life

Model | Power | Flow | Db noise | Fans D | Size | Weight |

60T | 1.5kw | 46.8cbm/h | 63.5 | 1170mm | D2100*2150mm | 250Kg |

VI. Screw type compressor for air blowing

A screw-type compressor is used for generating airflow by employing rotating screws to compress and push air forward, providing efficient and consistent air blowing capabilities.

1. Silent and low vibration

2. User friendly design, optimized structure

3. low maintenance cost

4. High cooling efficiency

5. True direct driver

6. low energy loss

Model | Power | Pressure | Capacity | Output D | Size | Weight |

XLAM40A | 40Hp | 10Bar | 4.3cbm/min | G11/4 | 1200*950*1358mm | 620kg |

VII. Conveyor for sending deflashing part

The conveyor belt designed for transporting IBC tank plastic parts after deflashing.

1. Full automatic type

2. with motor

3. height adjustable

4. with saftey button

5. with easier maintenance

6. with low noise

Model | length | height | Width | Capacity | Size | Weight |

TQ1000C | 2M | Based on granulaotor H | 800mm | 500Kgs | 2000*800*1.5M | 600kgs |

VIII. LEAK TESTER for valve connection

The leak test machine can detect if the valve connection of IBC tank is leaking or not.

1. With conveyor for easier up and down

2. With precise test result

3. can be connected with full automatic line

4. result showing on screen

5. time can be set adjustably

6. withe easier maintenance

Model | Air pressure | Pressure time | Slide guide | Air part | Size | Weight |

HJ1000LK | 0.5Mpa | 5 minutes | SBR | AIRTAC | 2000*2000*2340mm | 1T |

IX. Vibration tester for IBC tank with frame

1. IBC table Strong quality with long life

2. Touch screen shows vibration frequency

3. Vibration motor with eccentric wheel and spring, reach 25mm vertical amplitude;

4. separate control box and main body, safe operation

5. easy installing and stable running

6. Table Stainless steel 304, no rusting, no deforming

7. vibration table with variable frequency type, strong overloading ability

8. with over-speed protection, prevent safety

Model | Frequency | Amplitude | Big loading | Table size | Time setting | Weight |

ZDZD1-IBC | 2-5Hz 100-300rpm adjustable | Vertical type 25mm | 2000kg | 1200*1200mm | 0-999hours adjustable | 800kgs |

Our IBC tank blow molding machine stands as a testament to innovation and efficiency in the realm of industrial production. With a focus on precision, stability, and adaptability, our machines elevate the creation of IBC tanks to new heights. Whether it's the single-layer simplicity or the advanced capabilities of our double-layer system, we're dedicated to meeting and exceeding your production needs. Experience the future of IBC tank manufacturing with us, where excellence is not just a goal, but a standard.