Blow molding and roll molding are common plastic molding processes. What's the difference between blow molding and roll molding? Which molding process is better? This article will give you the exact answer.

First, let's understand the concepts of blow molding and roll molding. To understand the difference between blow molding and roll molding processing technology.

What is the blow molding process?

Also known as hollow blow molding, raw materials after extrusion or injection to form plastic billet. When it is hot, it is put into the open die, and compressed air is passed into the blank after the die is closed, so that the plastic blank is blown and close to the inner wall of the mold. After cooling, the mold is released to form a variety of hollow blow molding products.

What is the rolling process?

Also known as roll molding, rotary molding, rotary molding, is a plastic hollow molding method. The raw materials are added to the mold, and the mold is continuously rotated and heated along two vertical axes. The raw materials in the mold are gradually evenly coated and fused to adhere to the entire surface of the mold cavity under the action of gravity and heat energy, and initially formed into the required shape. After cooling, the corresponding rolling products are formed.

Next, the difference between blow molding and roll molding will be compared from different aspects.

Blow and roll machine structure

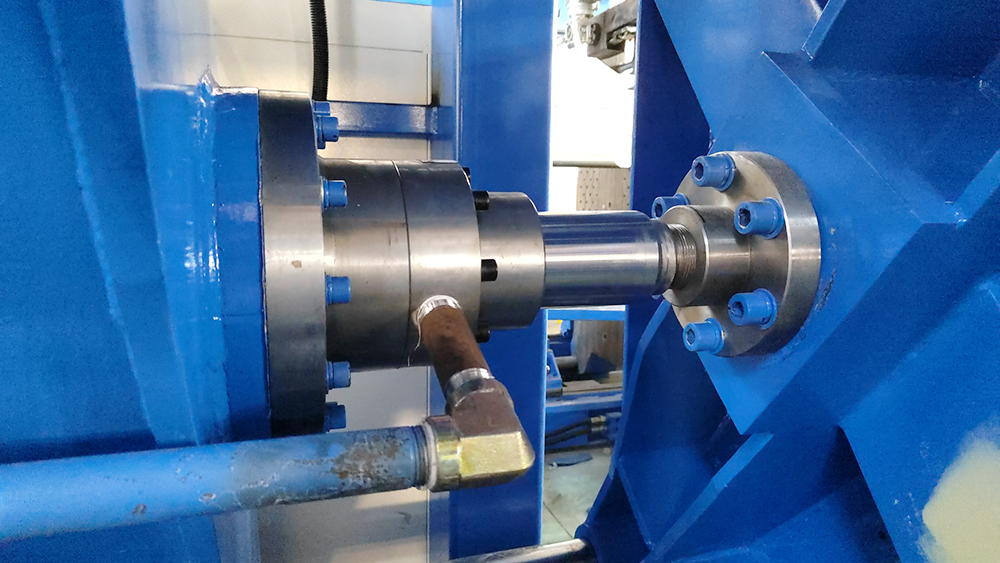

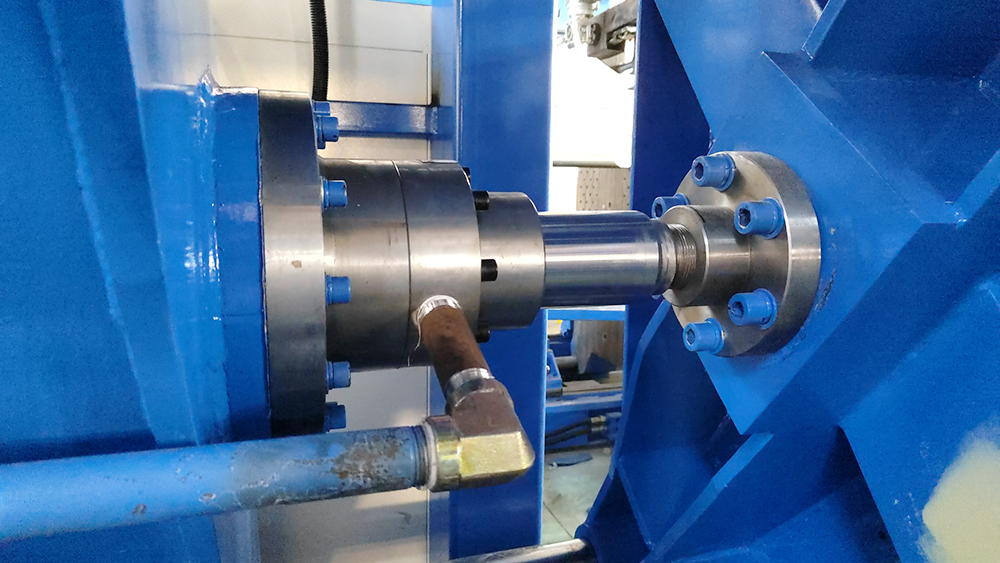

Hollow blow molding machine covers a small area, simple structure, easy operation, only need 3-4 people can.

Rolling machine covers a large area, simple structure, but the operation is more complex, often need a lot of labor.

Production efficiency of blow molding and roll molding

Blow molding products generally choose high molecular weight high density polyethylene resin, through the extrusion of a blow molding. The molding process is fast and sufficient; Product forming full, internal quality and stable performance.

Yan Kang hollow blow molding machine can produce 18-20 plastic buckets per hour on average, such as 2000L buckets can produce 8-9 pieces per hour.

Rolling processing speed is slow, the same 2000L bucket, rolling per hour output is only 1-2 pieces.

In addition, rolling requires high raw materials and less plastic material is available. In addition, the raw materials need to be completely crushed, and the processing cycle is longer and the cost is high. Therefore, it is not suitable for mass production.

Blow and roll wall thickness control

High precision electronic blank programmer is generally used to control the wall thickness of blow molding process. The wall thickness control effect tends to be more stable and uniform. Some small areas of wall thickness control, such as the corner of the bucket, are also better handled by blow molding techniques.

High precision MOOG wall thickness controller is adopted to make the wall thickness of blow molding products more stable and stable.

The raw material handling process of blow molding and roll molding

The raw materials in the blow molding process are completely uniformly melted and melted under great pressure to force them through the die head.

The raw material is first crushed using an additional time and process, and the powder is coated on the inside of the rolling mold at zero pressure.

Blow molding can complete the processing of raw materials to the production of products at one time, while roll molding needs to deal with raw materials in advance, which requires extra manpower and time.

Raw material requirements for blow molding and roll molding

Although the blow molding process generally uses high molecular weight high-density polyethylene resin, but in fact, the requirement for raw materials is relatively low, there are many materials to choose.

The processing technology of rolling has high requirements on raw materials and few choices.

Blow and roll multi - layer product production

Multilayer blow molding products use a strong UV stabilized outer layer, a black intermediate layer, and a raw polymer inner layer that is in direct contact with drinking water. Multiple layers can be formed simultaneously during the blow molding process, so the bond between each layer is very tight.

The hollow blow molding machine of Yakang Plastic Machinery adopts multi-layer die head technology. Achieve multi-layer product production. Improve the recycling rate of materials, reduce the cost of materials, improve the production efficiency.

In the rolling process, each layer needs to be added separately in each molding process, which will lead to a smaller degree of adhesion between each layer, can not guarantee the quality of the product, but also cause a waste of manpower and time.

Blow and roll product comparison

Which is of better quality and stronger, blow molding or roll molding?

The answer, of course, is blow molding products.

The products produced by blow molding process have good color, light weight, thick and uniform wall thickness and good quality. Because the plastic is melted by fire and then cooled, the factors affecting the quality of the product are difficult to control. There are often quality problems such as uneven wall thickness, large size error and impurities on the surface of the product.

Blow and roll energy consumption

The production process of blow molding process generally adopts automatic intelligent control system, electricity is guaranteed, stable operation, can realize automatic feeding, automatic opening and closing mold, automatic production process.

The production process of blow molding products is more environmentally friendly than that of injection molding. The whole process of closed production will not produce environmental pollution factors. It also ensures a working environment for workers.

In addition, blow molding is more energy efficient than roll molding in terms of energy consumption.

Induction heaters for die head and extruder are used in the design and production of hollow blow molding machine, which can save 40% to 50% energy. The clamping device of the machine adopts servo motor, which can save energy by 40 percent. The reduction in energy consumption also saves some production costs.

There is a lot more human work involved in rolling than in blowing. For example, during the production of roll molding, specialized workers are needed to open and close the molds. Opening and closing die is a heavy manual labor. It requires a lot of labor and labor costs.

The fuel used in rolling keeps temperatures at very high levels, which can be dangerous to workers or the process of adding raw materials. The burning of fuel also produces gases that pollute the environment.

After producing a product, in order to produce the next product as soon as possible, when the mold is still very hot, cold water needs to be poured on it to cool it. The cost of fuel is very high, which causes a waste of resources.

The cost of blow molding and roll molding

This is a summary of the above content, according to what we said above, it should be able to see that the cost of blow molding process is lower, the need for less labor, high production efficiency, low material requirements, low material cost, less energy consumption and so on.

The above is about the comparison of blow molding and roll molding process. In the long run, blow molding processbrings us a wider range of benefits. There are so many advantages in the blow molding process, and the advantages of the hollow blow molding machine using the blow molding process are beyond doubt. For more industry news on hollow blow molding, welcome to continue to pay attention to Yan Kang plastic machinery.