Are you struggling to keep up with the increasing demand for IBC tanks in your industry? Is your current production capacity hindering your ability to capitalize on growth opportunities? If so, it's time to revolutionize your approach and unlock the true potential of your business.

In today's competitive marketplace, having a robust IBC tank production capacity is not just a luxury, but a necessity. The demand for these versatile containers is soaring across various industries, from chemicals and pharmaceuticals to food and beverages. Meeting this demand requires a strategic focus on enhancing your production capacity to stay ahead of the curve.

In this article, we will explore the importance of IBC tank production capacity and how it can be the catalyst for your business's success. We will dive into the key strategies and innovative technologies that can empower you to boost your production capabilities, streamline operations, and seize lucrative market opportunities. So, let's embark on this journey together and unlock your business's growth potential by maximizing your IBC tank production capacity.

IBC tanks have become a staple in numerous industries due to their versatility, durability, and ease of transport. From storing and transporting chemicals, liquids, and granular materials to serving as intermediate bulk containers, their demand continues to rise. As far as the analysis of the IBC ton barrel application market is concerned, the storage and transportation of chemical products currently occupy the main market, accounting for about 80%. IBC tons of barrels can also be used for the storage of petroleum products, accounting for 15% of this field.The plastic and steel materials used in IBC tonnage barrels are about 65% of those of plastic barrels of the same volume, but compared with ordinary plastic barrels, the transportation and loading efficiency is about 16% higher.

With such a high demand, it's crucial for manufacturers to ensure efficient production processes. Customers expect timely delivery of their orders while maintaining high product quality. This is where the significance of a complete 1000Lt IBC tank production line comes into play. By streamlining operations and optimizing productivity, manufacturers can meet customer demands while maximizing profitability.

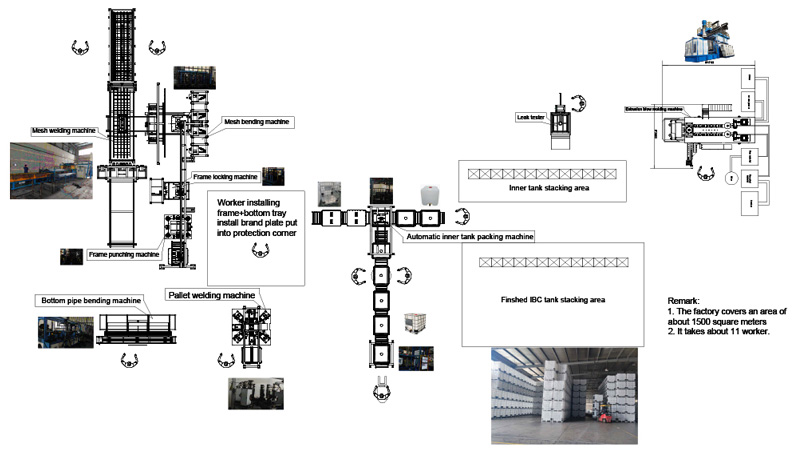

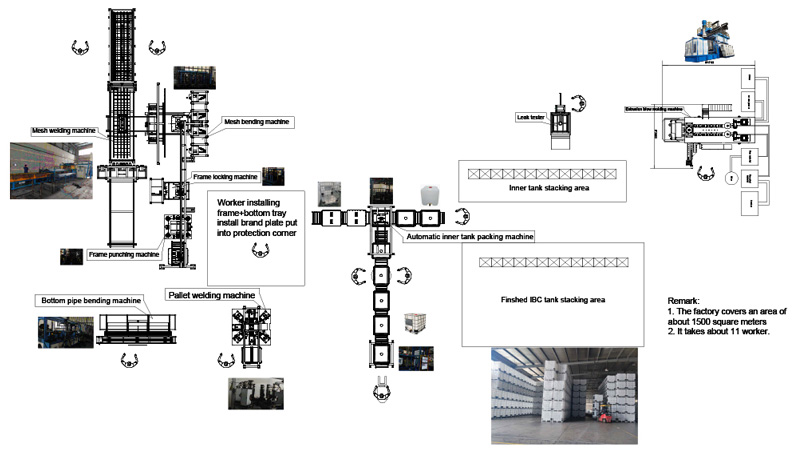

To establish a complete 1000Lt IBC tank production line, several essential equipment and machinery components are necessary. Let's explore each of these components and their role in the manufacturing process:

1.HDPE container production

Extrusion Blow Molding Machine: This machine is at the heart of the production line and is responsible for shaping the IBC tanks. It utilizes advanced extrusion and blow molding techniques to form the tanks from high-density polyethylene (HDPE) or other suitable materials.It consists of extrusion blow molding machine, IBC tank mold, chiller, air compressor, auto-loading machine, mixer, crusher.

1000L IBC tank production capacity:500 pcs per day

2.Metal outer frame production

The outer frame consists of mesh welding machine, mesh bending machine, iron frame locking machine,flattening punching machine.

Ø Mesh welding machine

This machine is used to weld steel tubes into a grid.This machine is used to weld steel tubes into a mesh.

Ø Mesh bending machine

It bends the metal mesh into a metal frame. Bend the ends once, then bend the middle again.

Ø Iron frame locking machine

It is used to lock the metal frame. The shape of the iron frame is fixed.

This machine need 1 person to control it.

Ø Flattening punching machine

This machine is used to flatten the metal pipe and punch it. This purpose of this process is to fix the metal frame and bottom pallet with screw.

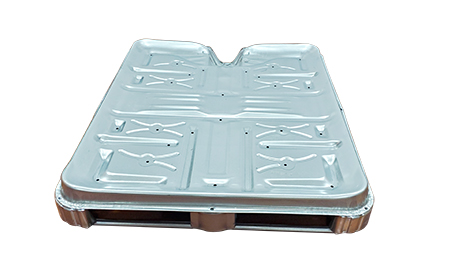

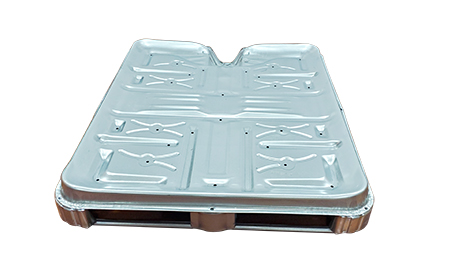

3. Bottom pallet

The bottom pallet production line consists of bottom pipe bending machine, pallet welding machine.

Ø Bottom pipe bending machine

This machine is used to bend the bottom pipe. It bends the steel pipe into a square.

Ø Pallet welding machine

It welds the bottom square tube together with four supporting feet and a strengthening plate.

By integrating these key components in a complete 1000Lt IBC tank production line, manufacturers can achieve high productivity, consistent quality, and improved operational efficiency. In the next section, we will explore the process optimization strategies and workflow management techniques that further enhance productivity in IBC tank manufacturing, allowing manufacturers to meet customer demands effectively.

Customer Case

For more customer cases, please contact us

In the quest for enhanced productivity and streamlined operations, advanced technologies and automation play a crucial role in the success of a complete 1000Lt IBC tank production line. Let's explore some of these cutting-edge advancements:

Robotic Systems:

Robotic automation has revolutionized the manufacturing industry, and the production of IBC tanks is no exception. Robots can be deployed to perform various tasks such as material handling, mold loading and unloading, quality inspection, and packaging. Their precision, speed, and reliability not only improve efficiency but also ensure consistent quality throughout the production process.

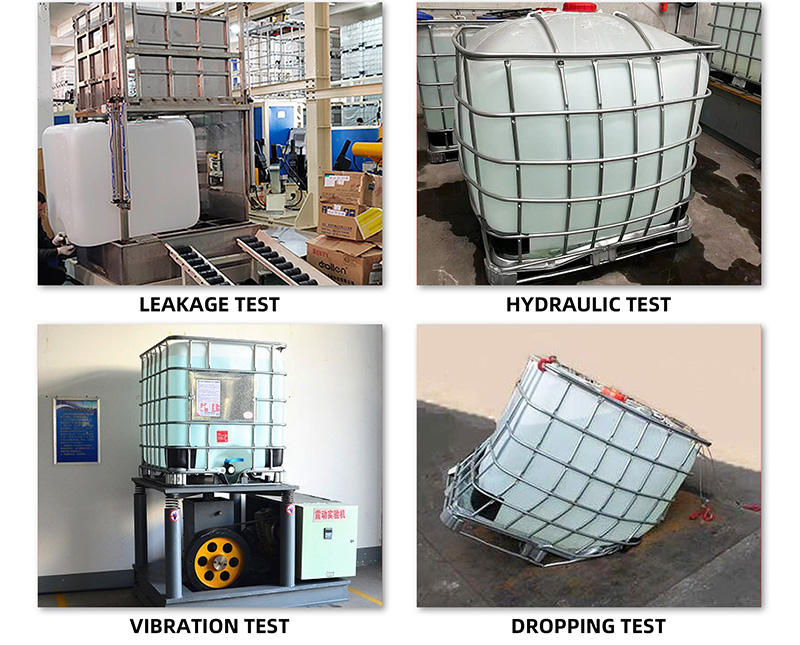

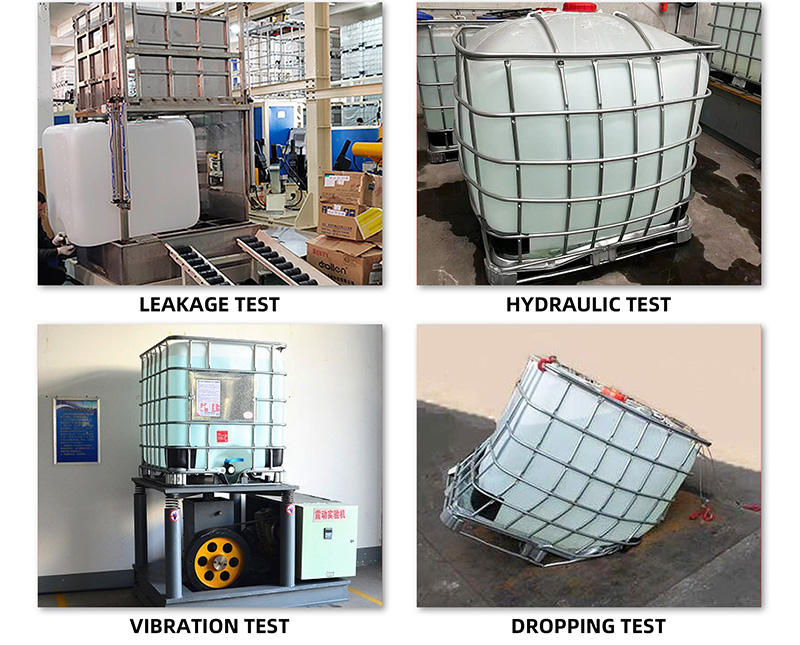

Leakage detection of IBC drum:

tighten the valve and seal it for leakage detection. Inject compressed air into the container, the pressure reaches 20KPa, keep the pressure for 10min, no leakage , enter the next production process.

Vibration tester

Fill the container with 98% water, and at a certain frequency, any two sides of the bottom tray and the angle between them can jump up with the sine wave, which is enough to insert a steel plate with a thickness of 1.5mm and a length of 100mm. Keep vibrating for one hour, the IBC barrel will not be damaged, and the key parts will not be deformed and damaged that affect safe use.

Ensuring the highest level of quality is paramount in the production of IBC tanks. Implementing robust quality control measures is essential to meet stringent industry standards and customer expectations. Here are some key aspects of quality control:

1.Statistical Process Control (SPC): SPC techniques enable manufacturers to monitor the production process in real-time, identifying any variations or deviations from the desired specifications. By analyzing data and taking corrective actions promptly, manufacturers can maintain consistent quality and minimize defects.

2.Non-Destructive Testing (NDT): NDT methods, such as ultrasonic testing, can be employed to detect internal flaws or structural abnormalities in the IBC tanks without causing damage. This ensures the integrity of the tanks and enhances product reliability and safety.

3.Quality Assurance Procedures: Implementing rigorous quality assurance procedures throughout the production line, from raw material inspection to final product testing, helps maintain the highest quality standards. This includes comprehensive quality checks, traceability systems, and adherence to relevant certifications and regulations.

By leveraging advanced technologies and implementing robust quality control measures, manufacturers can significantly boost efficiency and ensure the production of high-quality IBC tanks. In the next section, we will explore real-world case studies of companies that have successfully implemented these strategies, highlighting their achievements and the positive impact on their productivity and profitability.

If you are producing IBC drums, please feel free to contact us. We can give you the complete production line plan, plant design and investment budget.

By taking action and investing in a complete 1000Lt IBC tank production line, you position your business for success, profitability, and a competitive edge. Don't wait—seize the opportunity now and revolutionize your output.

Remember, the possibilities for your business are endless when you invest in the right tools and strategies. Take the leap and embrace the advantages of a complete production line. Your success starts today.