Solutions to blow molding product processing failures

Several problems are prone to occur during the blowing process of blow molding products. The bottle is blown, the bottom is aggregated, the bottom is not correct, the bottle body is thin, the bottle is white, etc. How to distinguish whether it is a blowing problem or a bottle embryo problem? Now we analyze the blow molding process from the different conditions on the blown bottle.

The reasons for the broken bottle:

1. The embryo tube is not heated enough, and it is not baked completely;

2. The stretching rod is not pulled in place (to the end);

3. The speed of the stretching rod is too slow;

4. The temperature protection is turned on, but the upper and lower temperature limits are set too high.

Solutions to blow molding product processing failures:

1. Increase the voltage with the same output. The output is reduced when the voltage remains unchanged, that is, the time for the second blow is lengthened.

2. Exhaust after the mold is closed, push the stretch rod to the bottom of the mold by hand to contact with the bottom of the mold, and tighten the limit nut. (Only limited to mechanical limit cylinder adjustment).

3. Adjust the throttle valve on the stretching cylinder to a larger size.

4. Lower the lower limit temperature. Generally, the PET preform is set to 85~95 degrees, and the upper limit can be set to 125~130 degrees.

The daily use of blow molding products needs attention

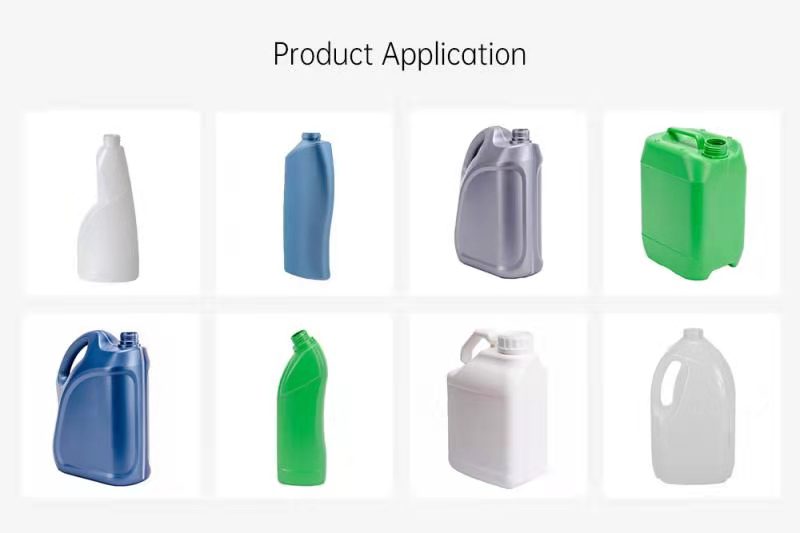

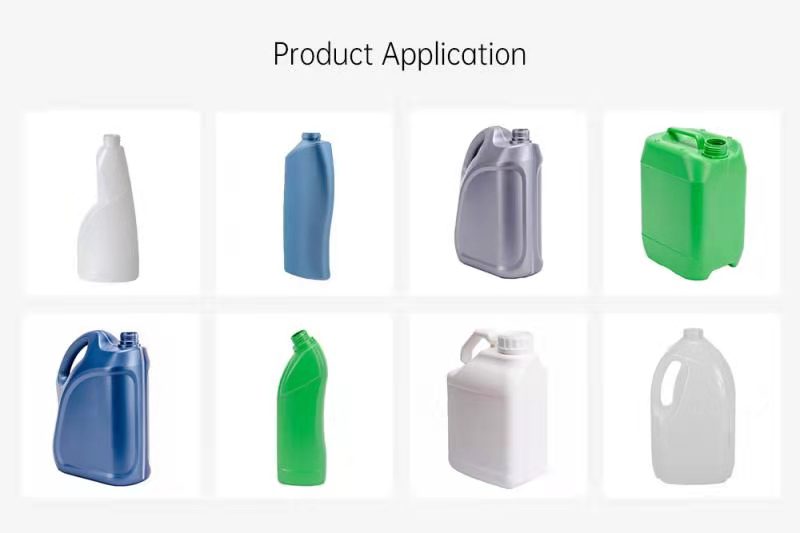

Introduce the aspects that need attention and precautions when using blow molding products in daily life.

In recent years, the technology of blow molding processing has been continuously matured and improved, so that all aspects of our production and life are inseparable from blow molding products, such as the various plastic products we use every day and the toys that children play with. One, but if it is not used normally, it will cause damage to the blow-molded product, and it will cause harm to people's body. Therefore, the following aspects should be paid attention to in the use of Shanghai blow-molded products.

1. When we buy blow-molded products, we can simply understand their production materials and precautions for use. There will be detailed instructions in the instructions of general products.

2. Secondly, plastic products such as garbage bags and plastic bottles that we use every day are generally made of polyethylene plastic, which is flammable but non-toxic, but many industrially used polyvinyl chloride is not easy to burn and is toxic. Therefore, special attention should be paid when using it.

3. Avoid using blow-molded products to hold edible products such as edible oil, salt, monosodium glutamate, etc. Although most of them are non-toxic, chemical reactions and oxidation will also occur when placed for a long time, and people will eat them over time. still harmful.

4. Do not use barrels to pack kerosene, gasoline, diesel, toluene, ether, etc., because these items are easy to soften and swell the plastic until it cracks and damages, which will eventually cause great pollution to the surrounding environment.

5. Pay attention to the aging and damage of blow-molded products, not to mention that the aging will be accelerated under the sunlight. Even if we use it normally, the blow-molded products will naturally age when the time is too long, so the conditions allow regular maintenance. Replace it or add some anti-aging agent to slow down its aging rate.

6. Avoid exposure to sunlight, rain and avoid contact with objects close to high temperature during use.

7. Don't throw the waste blow molding products randomly, put them in toxic and harmful trash cans for recycling, and never burn them on the spot, bury them, etc., which will pollute the environment and ultimately affect people's health. an injury.

8. If conditions permit, there is still a choice of high-quality blow-molded products.