Unleash the Future of IBC Tank Manufacturing with HUAN MACHINERY! Discover the power of our cutting-edge machines, designed to transform your production line into a powerhouse of efficiency and precision. With our innovative layouts and advanced features, we redefine what's possible in IBC tank manufacturing. Experience unrivaled productivity, uncompromising quality, and stay ahead of the competition. Get ready to revolutionize your business with HUAN MACHINERY.

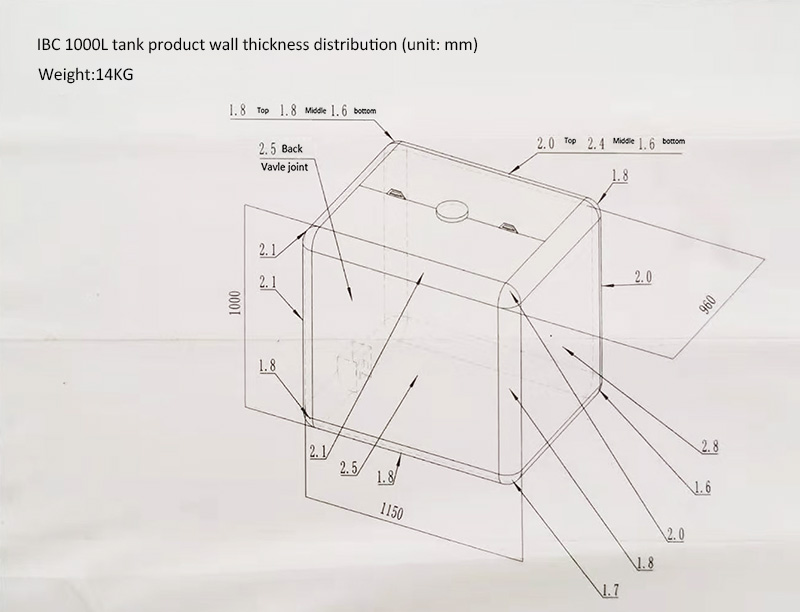

With precision-driven technologies, we ensure consistent wall thickness, guaranteeing the structural integrity of each IBC tank. Our automated systems for cage making and welding deliver uniform results, enhancing durability and strength. And with integrated bottom pallet welding and intelligent control systems, you can rely on stability and reliability, elevating the overall quality of your products.

Embrace the next generation of layout and features with HUAN MACHINERY. Experience the transformative power of our machines and witness the remarkable impact on your productivity and product quality. Contact us today and embark on a journey of excellence in IBC tank manufacturing. Together, let's shape the future of the industry.

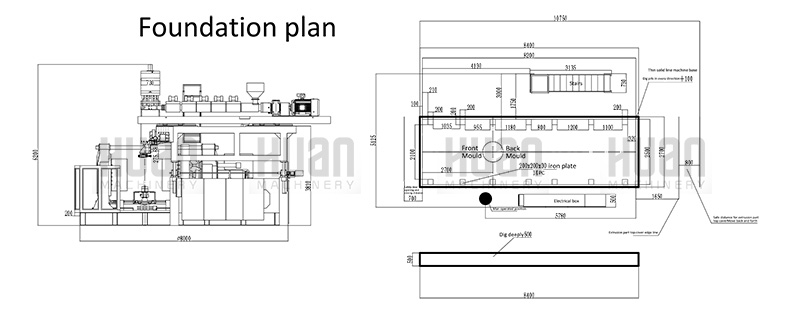

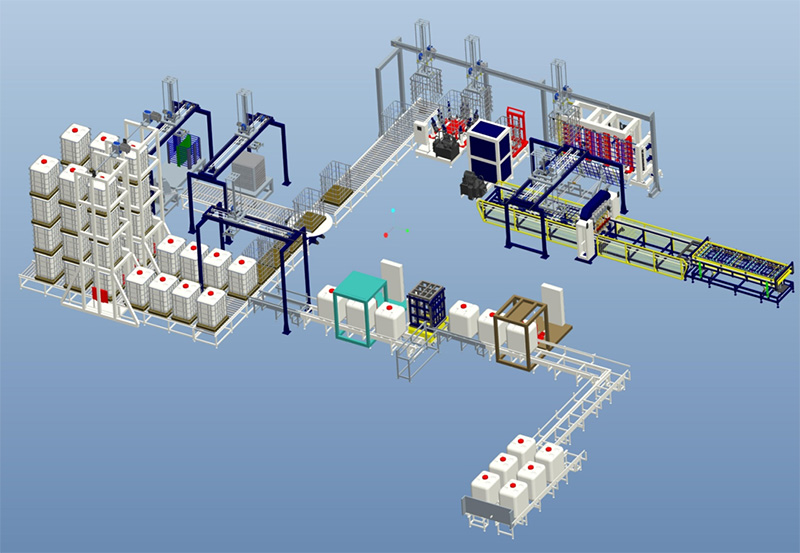

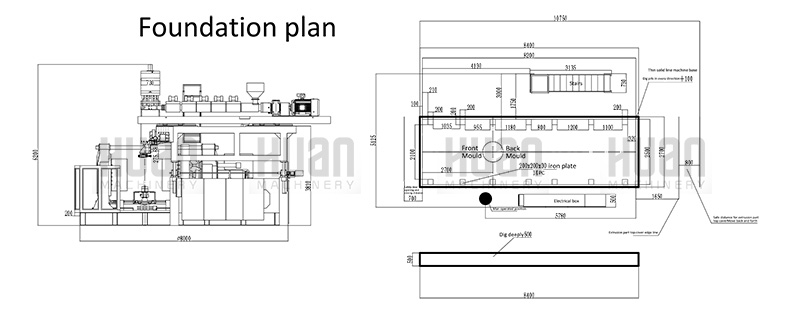

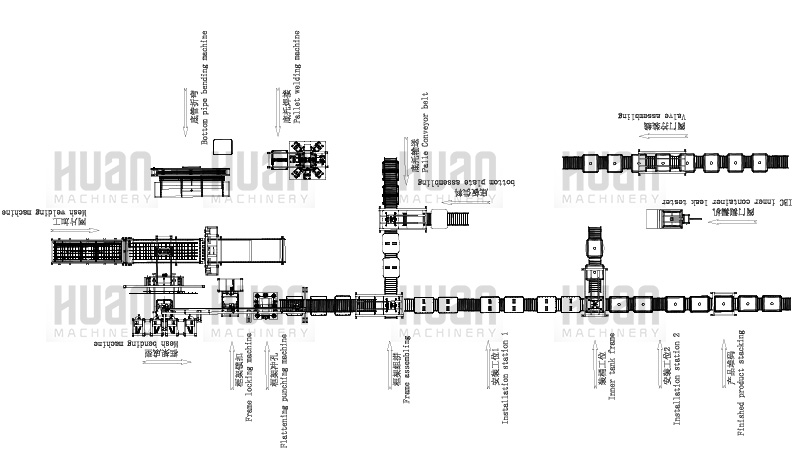

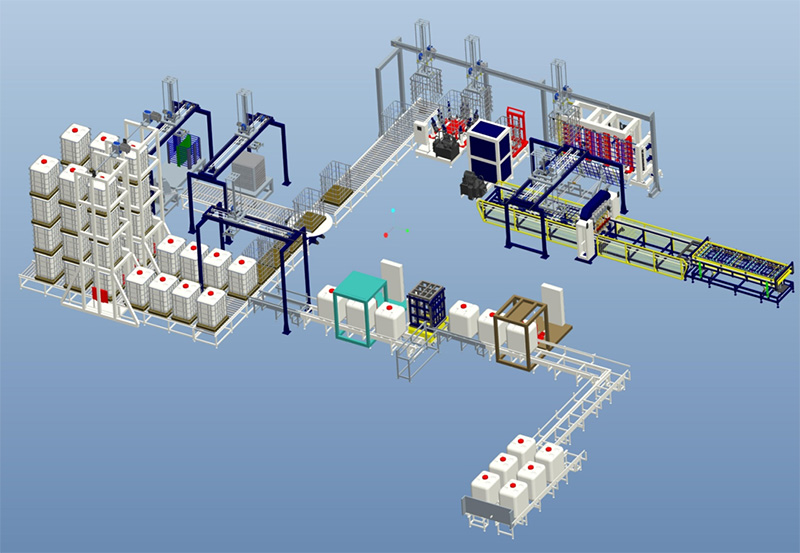

In the world of IBC tank manufacturing, an efficient layout is the foundation of success. At HUAN MACHINERY, we understand the critical importance of a well-designed production floor that enhances workflow and minimizes unnecessary material handling. Our expert team has meticulously crafted layouts that elevate your manufacturing process to new heights.

A. Designing a layout that maximizes workflow and minimizes material handling

With our advanced layout designs, every step of the production process seamlessly flows from one stage to the next. We strategically position machines, workstations, and storage areas to minimize material transportation and eliminate bottlenecks. The result? A streamlined production line that optimizes efficiency and reduces costly downtime.

B. Incorporating ergonomic considerations for operator convenience and safety

At HUAN MACHINERY, we prioritize the well-being of your operators. Our layouts are meticulously planned to ensure ergonomic workstations, reducing operator fatigue and minimizing the risk of injuries. From adjustable heights to intuitive controls, our machines are designed with operator convenience and safety in mind, allowing them to focus on delivering exceptional results.

C. Utilizing space efficiently to accommodate different machine components

Space is a valuable asset in any production facility. Our layouts are thoughtfully designed to make the most of every square foot, ensuring optimal utilization of the available space. We consider the placement of each machine component, storage areas, and auxiliary equipment, maximizing efficiency without compromising functionality.

By choosing HUAN MACHINERY, you're investing in a layout that maximizes productivity, optimizes material flow, and prioritizes the well-being of your operators. Experience a harmonious production process that enhances both efficiency and safety. Contact us today to discuss how our optimized layout solutions can revolutionize your IBC tank manufacturing business.

At HUAN MACHINERY, we go beyond just efficient layouts. Our IBC tank production machines are equipped with cutting-edge features that redefine performance standards. From high-speed precision-driven technology to comprehensive inspection mechanisms, our advanced features are designed to elevate your manufacturing process to new heights.

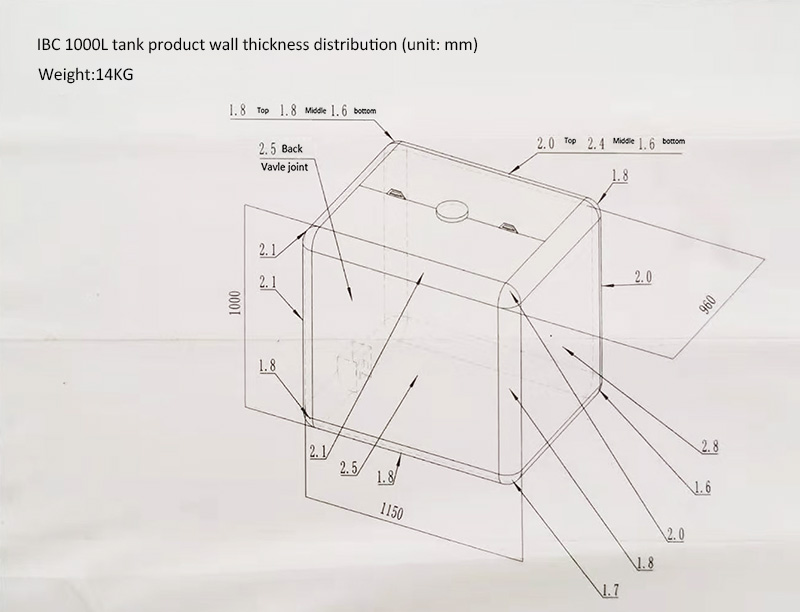

A. High-speed and precision-driven blow molding technology

Our state-of-the-art blow molding technology delivers exceptional speed and precision, ensuring consistent quality and uniform wall thickness. With advanced controls and innovative design features, our machines produce IBC tanks with superior strength and structural integrity, meeting the demands of even the most rigorous applications.

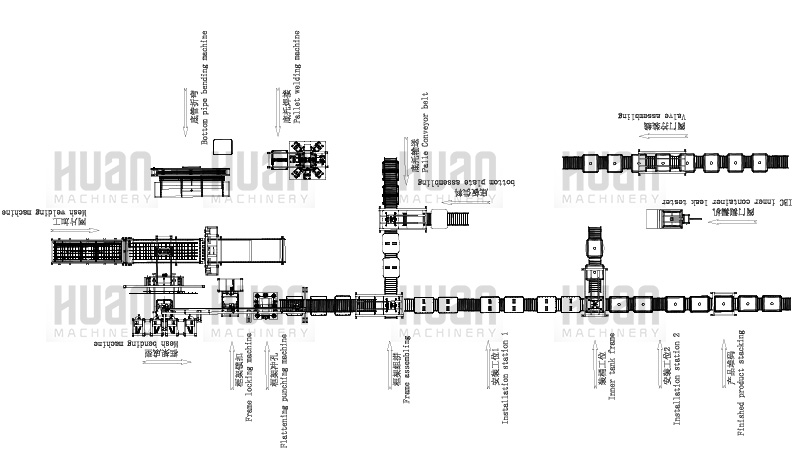

B. Automated cage making and welding systems for consistent and reliable production

Our automated cage making and welding systems eliminate human error and ensure consistent and reliable production. With precise positioning and advanced welding techniques, the cages are securely welded to the tank body, providing unmatched durability and stability.

C. Integrated bottom pallet welding line for seamless integration and strength

Our integrated bottom pallet welding line seamlessly joins the tank body with the pallet, enhancing structural strength and stability. With precise alignment and advanced welding technology, our machines create a robust connection that can withstand heavy loads and challenging handling conditions.

D. Efficient IBC assembly line with intelligent control systems

Our IBC assembly line incorporates intelligent control systems that streamline the assembly process. From automatic feeding and precise positioning to synchronized operations, our machines ensure efficient and error-free assembly, reducing production time and enhancing overall productivity.

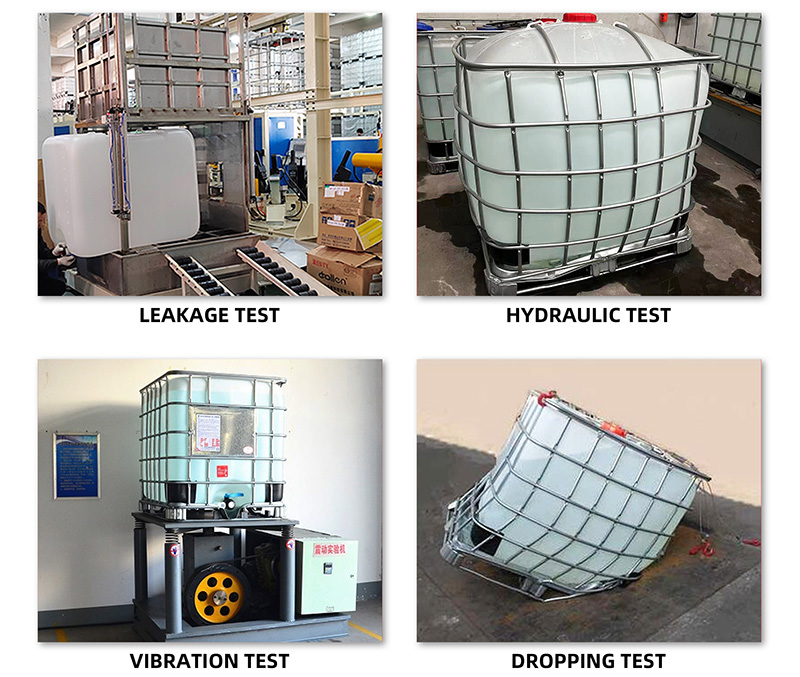

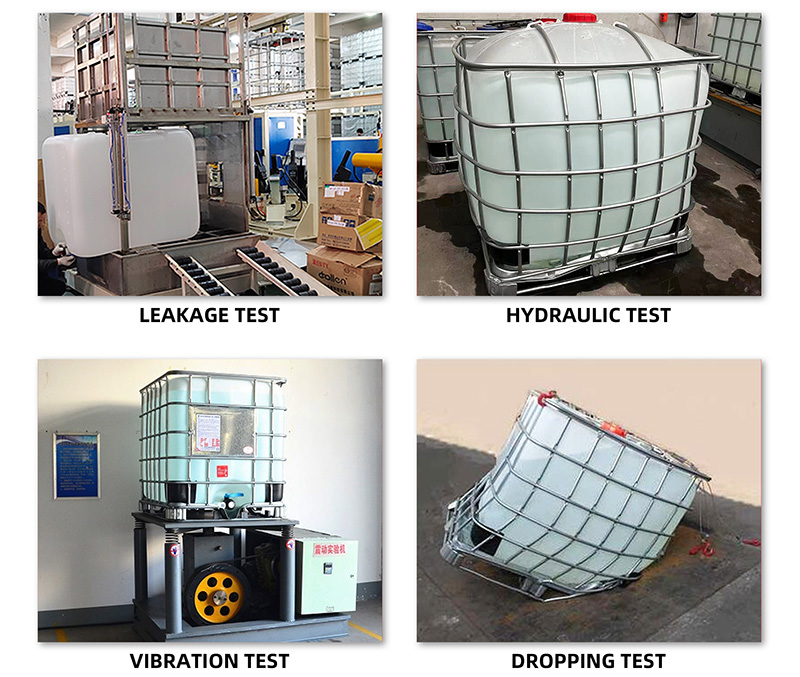

E. Comprehensive inspection mechanisms for quality assurance

Quality is our top priority. Our machines are equipped with comprehensive inspection mechanisms that meticulously examine every aspect of the IBC tanks. From wall thickness measurement to leak testing, our inspection systems ensure that each tank meets the highest quality standards before leaving the production line.

By choosing HUAN MACHINERY, you gain access to advanced features that propel your IBC tank manufacturing to new levels of performance. Our high-speed blow molding technology, automated cage making and welding systems, integrated bottom pallet welding line, efficient assembly line, and comprehensive inspection mechanisms are the keys to producing superior-quality IBC tanks consistently.

Invest in the future of IBC tank manufacturing. Contact HUAN MACHINERY today to discuss how our advanced features can revolutionize your production process, boost efficiency, and elevate the quality of your products.

Investing in next-generation machines for your IBC tank manufacturing can revolutionize your operations and deliver a range of impressive benefits. At HUAN MACHINERY, we understand the importance of maximizing productivity, ensuring product quality, and optimizing efficiency. Let's delve deeper into the advantages of our next-generation machines:

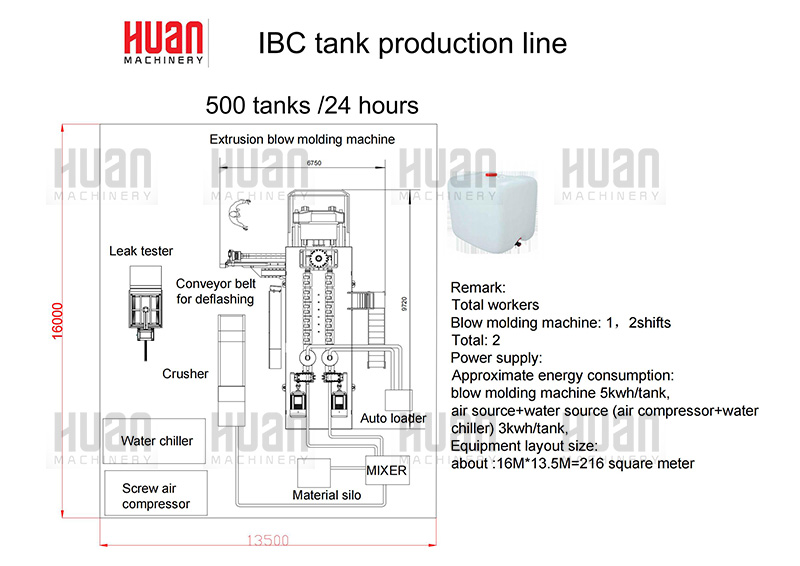

A. Increased production capacity and output rates

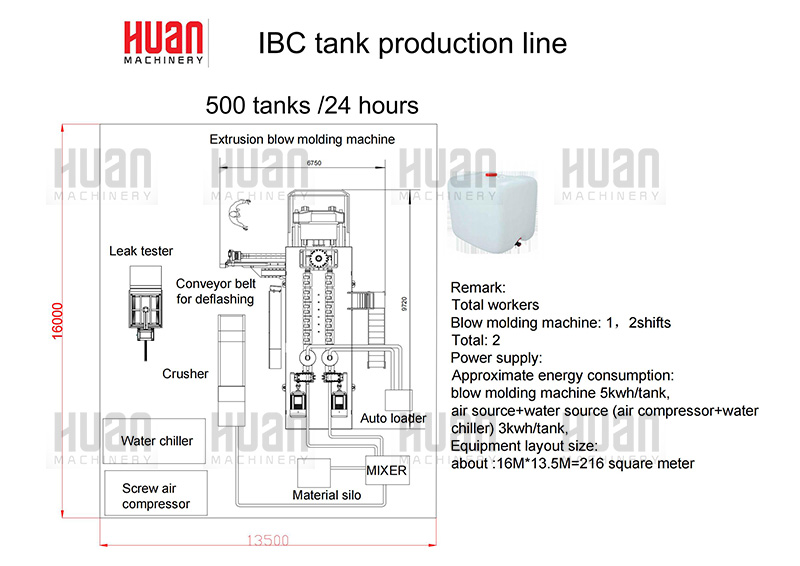

With our state-of-the-art machines, you can significantly enhance your production capacity and output rates. Our advanced technology and optimized workflows enable faster cycle times and seamless integration of various production stages. This means you can meet higher demand, fulfill larger orders, and expand your market reach.We can customize IBC tank production line according to your different production needs.

B. Improved product quality and consistency

Delivering superior product quality and consistency is crucial for customer satisfaction and brand reputation. Our next-generation machines incorporate cutting-edge features that ensure precise control over the blow molding process, resulting in uniform wall thickness, exceptional structural integrity, and consistent product dimensions. Your customers will appreciate the high-quality IBC tanks that meet their exact specifications.

C. Enhanced operator efficiency and reduced labor costs

We believe that empowering operators with efficient machines is key to improving overall productivity. Our next-generation machines are designed to enhance operator efficiency by streamlining processes, automating repetitive tasks, and providing user-friendly interfaces. With reduced manual intervention, your operators can focus on critical tasks, increasing their productivity while minimizing labor costs.

D. Minimized downtime and maintenance requirements

Unplanned downtime and excessive maintenance can hamper your production efficiency and profitability. That's why our next-generation machines are engineered for reliability and ease of maintenance. Built with high-quality components and equipped with advanced diagnostics, our machines offer robust performance and streamlined maintenance procedures. By minimizing downtime and reducing maintenance requirements, you can optimize your production schedules and maximize profitability.

E. Compliance with industry standards and regulations

Ensuring compliance with industry standards and regulations is vital for maintaining product quality, safety, and market credibility. Our next-generation machines are meticulously designed and manufactured to meet rigorous industry standards and regulatory requirements. By investing in our machines, you can have confidence in the compliance of your IBC tank production processes, providing peace of mind to both you and your customers.

As you can see, the benefits of our next-generation machines extend far beyond just improving your manufacturing processes. With increased production capacity, improved product quality, enhanced operator efficiency, minimized downtime, and compliance with industry standards, you gain a competitive advantage in the market.

At HUAN MACHINERY, we are dedicated to helping you unlock the full potential of your IBC tank manufacturing. Contact us today to learn more about our next-generation machines and explore how they can elevate your production capabilities, drive growth, and position your business for success.

HUAN MACHINERY has successfully provided 100 units of IBC blow molding machines and constructed 20 complete production lines in the Chinese market. With years of extensive experience, we specialize in customizing IBC tank production line machine configurations based on our customers' production site size, requirements, and specifications.

If you are interested, we warmly welcome you to visit our factory for an on-site inspection. Our team will assist you in the installation of the production line and provide comprehensive on-site training for up to one month. This ensures that all components of the production line operate smoothly and reliably.

We take pride in our expertise and strong competitive edge in the industry. Our commitment to delivering high-quality machinery, personalized solutions, and exceptional customer service sets us apart. We understand the importance of tailored production solutions, and our experienced team will work closely with you to meet your specific needs and exceed your expectations.

From optimized layout and advanced features to increased production capacity, improved product quality, enhanced operator efficiency, minimized downtime, and compliance with industry standards, the advantages are substantial. The decision to adopt next-generation machinery can empower your business to stay ahead of the competition and meet the evolving demands of the market.

We encourage you to explore the possibilities and benefits that come with adopting next-generation machinery for your IBC tank production. At HUAN MACHINERY, we are committed to delivering cutting-edge solutions, exceptional customer support, and forging long-term partnerships. Contact us today to discuss your specific needs and discover how our next-generation machinery can revolutionize your IBC tank manufacturing.