Meeting Industry Demands: Unleashing the Power of High-Performance IBC Tank Blow Molding Machines

In today's fast-paced industrial landscape, meeting industry demands efficiently and effectively is paramount. As the demand for Intermediate Bulk Container (IBC) tanks continues to rise, the need for high-performance blow molding machines becomes increasingly critical. These machines not only streamline the production process but also deliver exceptional quality and productivity. In this article, we will explore the technological advancements and innovative features of high-performance IBC tank blow molding machines, and how they are revolutionizing the industry.

Understanding IBC Tank Blow Molding:

To comprehend the significance of high-performance blow molding machines, let's delve into the process itself. Blow molding plays a pivotal role in IBC tank manufacturing, where a molten polymer is extruded and shaped into a hollow form through the application of compressed air. This cost-effective and efficient method ensures the production of durable, lightweight, and versatile IBC tanks suitable for a wide range of industries.

The Need for High-Performance Machines:

1. Overcoming Industry Challenges:

Meeting industry demands requires overcoming various challenges, such as rising production volumes reach 26pcs per hour, shorter lead times 60 days, and stringent quality requirements. High-performance IBC tank blow molding machines rise to these challenges, enabling manufacturers to meet customer expectations with ease.

2. Advantages of High-Performance Machines:

These machines are equipped with advanced technology and innovative features that elevate production capabilities. With enhanced precision, consistency, and speed, manufacturers can achieve optimal results, reduce downtime, and improve overall efficiency.The machines are all branded parts,such as Siemens motor,GEFRAN Transducer,YUKEN valve etc.

Key Factors of High-Performance IBC Tank Blow Molding Machines:

1. Advanced Technology and Innovative Features:

High-performance machines integrate cutting-edge technology, including advanced control systems, intelligent automation, and real-time monitoring.Mitsubishi PLC,MOOG 100 wall thickness system.These features ensure precise control over the entire blow molding process, resulting in consistent product quality and reduced wastage.

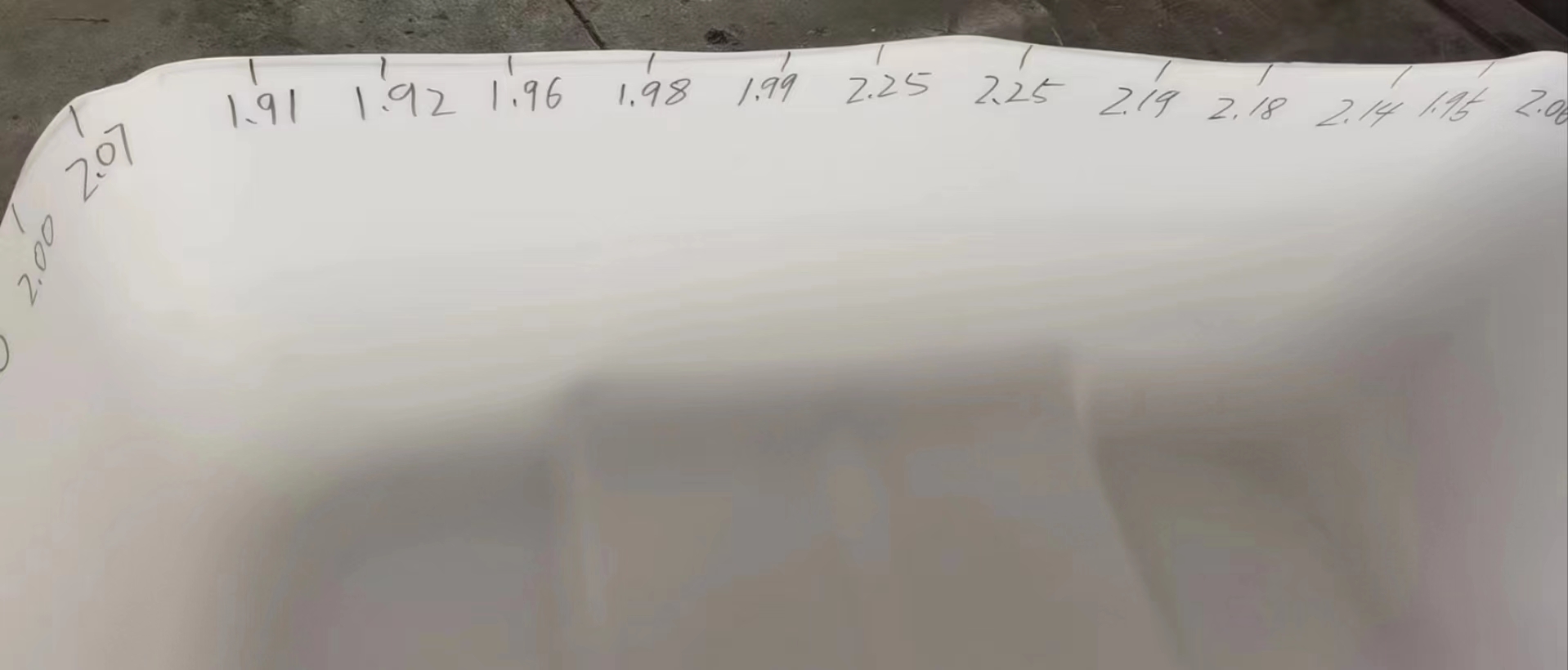

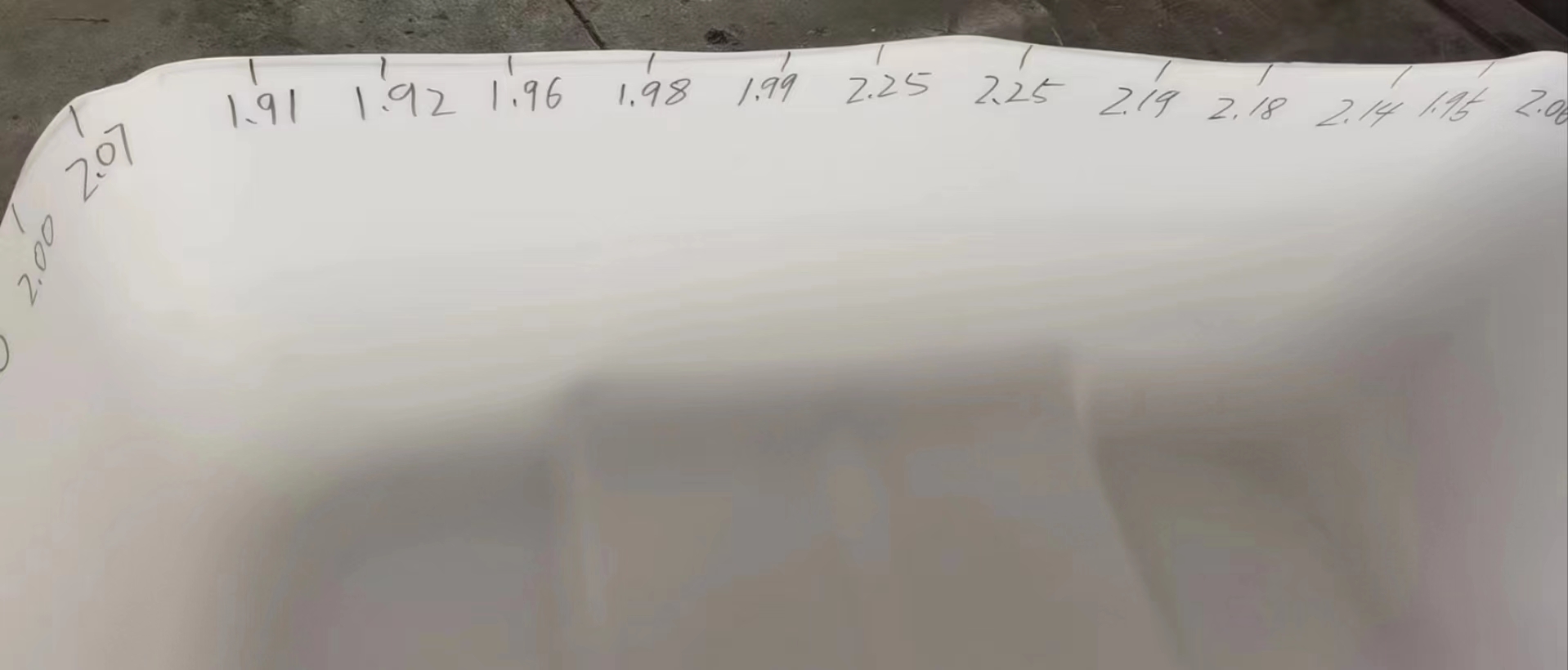

2. Precision and Consistency in Production:

High-performance machines employ advanced servo-driven systems and precise mold alignment mechanisms. This level of precision ensures uniform wall thickness, accurate dimensions, and minimized variability across IBC tank production, guaranteeing superior product quality.

3. Fast Color Change and Material Saving Capabilities:

Changeovers between different colors or materials can be time-consuming and wasteful. Our IBC tank blow molding machine can spend 2-4 hours to completely replace the old material.However, high-performance machines are designed with quick color change systems and efficient material management, reducing downtime and material waste while increasing operational flexibility.

4. High-Speed Output and Production Capacity:

With faster cycle times and increased output rates, high-performance blow molding machines significantly boost productivity. Manufacturers can meet growing demands while maintaining a competitive edge in the market.

Benefits for IBC Tank Manufacturers and End Users:

1. Improved Productivity and Efficiency:

High-performance machines optimize production processes, reducing cycle times and enhancing overall efficiency. Manufacturers can achieve higher output rates and meet tight deadlines, resulting in improved productivity and profitability.

2. Enhanced Product Quality and Consistency:

The precision and advanced features of high-performance machines ensure consistent product quality, minimizing defects and variations. This, in turn, enhances customer satisfaction and strengthens brand reputation.

3. Cost Reduction and Material Savings:

Efficient material management, faster changeovers, and optimized production processes lead to significant cost savings. Manufacturers can reduce material waste, energy consumption, and overall production costs, improving their bottom line.

4. Increased Flexibility and Adaptability to Market Demands:

High-performance machines enable manufacturers to respond quickly to market demands, adapting to changing customer requirements with ease. The versatility and efficiency of these machines empower businesses to stay ahead of the competition.

Case Studies and Success Stories:

To illustrate the transformative impact of high-performance IBC tank blow molding machines, let's explore a few success stories from real-world implementations:

High-performance IBC tank blow molding machines have emerged as game-changers in meeting industry demands. With advanced technology, precision engineering, and a focus on productivity, these machines enable manufacturers to optimize production processes, enhance product quality, and exceed customer expectations. By investing in high-performance machines, businesses can unleash their full potential, stay ahead of the competition, and thrive in the dynamic IBC tank market.

By providing valuable insights into the technological advancements and benefits of high-performance blow molding machines, this article aims to inspire manufacturers and end users alike to embrace these innovations and unlock new levels of success in the IBC tank industry.