Plastic PVC is also a kind of general plastic blow molding machinery with good function and low price, and it has many additives. It can be adjusted to the formula, and the function of the product can be changed greatly, for example, it can add less or no plastic agent to make hard plastic PVC products. Hard plastic polyvinyl chloride products have outstanding rigidity and both good water and moisture resistance and insulation oxygen, carbon dioxide and nitrogen through the function. Its oil resistance, transparency is also significantly better than polyolefin plastics. But for packaging discards back after use and burn wound disposal of all is relatively difficult, recycled use of analogy in the manufacturing process of simple differentiation, combustion disposal, will damage the environment materials such as hydrogen chloride, and the cost of energy, therefore, the use of plastic PVC in packaging were bound constraints, and follow us to know the progress of environmental protection, the use of it in terms of packaging, There is a gradual trend to be replaced by other plastics.

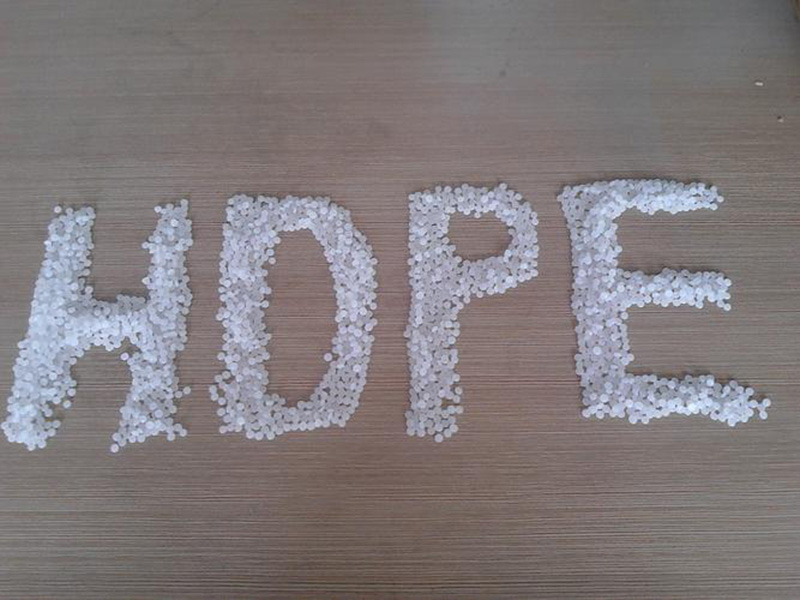

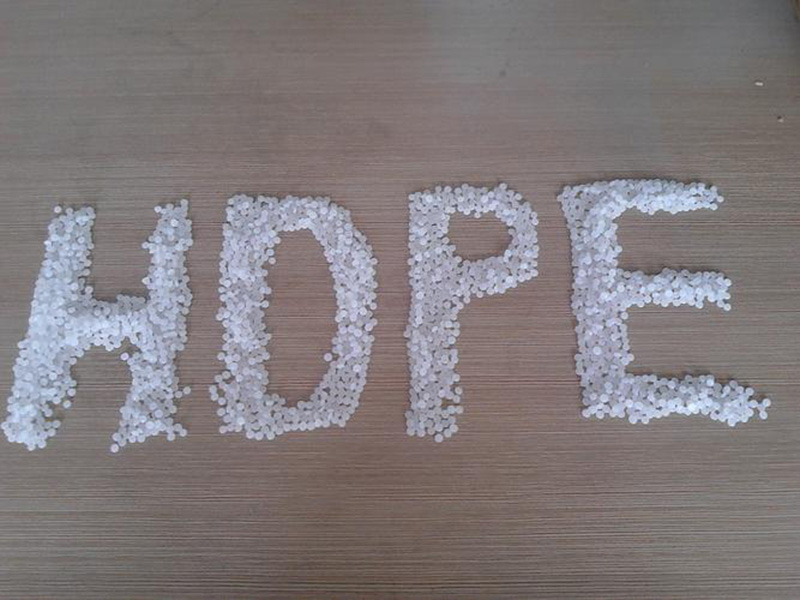

In several kinds of plastic polyethylene, high density polyethylene plastic is the best type of mechanical strength for polyethylene plastic, isolation of water vapor can is a kind of all kinds of plastic guess best, but in several kinds of plastic PE, it is flexible and transparency of the worst types, when demand was soft and transparency of products, should choose low density polyethylene plastic, The mechanical strength of linear low density plastic polyethylene is between high density plastic polyethylene and low density plastic polyethylene. Its biggest advantage is high puncture resistance, high tear resistance and stress cracking resistance. In addition, its thermal sealing function is also better than high density plastic polyethylene and general low density plastic polyethylene, therefore, it is a kind of outstanding substrate with film, one of its first defects is the molding processing function is slightly inferior.

Polypropylene and propylene copolymer, polypropylene and polyethylene plastic is the same, is a typical class of polyolefin polymer, thus there are many similar features, such as good chemical stability, non-toxic, odourless, tasteless, clean function strong, etc., and plastics polyethylene, polypropylene is the first advantage of good heat resistance, using the temperature can reach 120 degrees, Therefore, the composite bag with reduced propylene as heat seal layer is used for cooking and sterilization. In addition, the strength of polypropylene is significantly higher than plastic polyethylene, one of the biggest defects of polypropylene function is low temperature resistance function is poor, polypropylene homopolymer has a large brittleness at 0 degrees, propylene and a few ethylene copolymer can significantly improve the cold resistance of polypropylene, but heat resistance is also reduced accordingly.

Ethylene/vinyl acetate copolymer was used in the packaging is more of a vinyl polymer, its price is slightly higher than the plastic polyethylene, but in the kinds of cheap plastic guess is still compare, follow the add of vinyl acetate content, its cold resistance, softness, heat sealing improvement, progress of transparency, but when the vinyl acetate content above 10%, can appear sour, Do not touch food directly

Thermoplastics have function balance, convenient molding processing, recycling and discarding materials, convenient return to the furnace, product price is lower, a lot of advantages, used in plastic plastic packaging materials. The primary types are plastic polyethylene and ethylene copolymers, which include high density plastic polyethylene, low density plastic polyethylene, linear low density plastic polyethylene, ethylene, vinyl acetate copolymer, etc

Used as a plastic packaging material, and plastic polyethylene is very similar, polypropylene has outstanding moisture-proof, moisture-proof, but the isolation of oxygen, carbon dioxide, nitrogen and other non-polar gases is poor, when the commodity needs oxygen storage, need to choose the so-called isolation plastic packaging materials packaging, Perhaps choose polypropylene (plastic polyethylene) and insulating plastic packaging material composite products for plastic packaging materials.

Plastic polyethylene plastic is a typical polyolefin compound, non-toxic, odorless, tasteless, cleaning function is reliable, acid, alkali, salt and a variety of chemical substances, function stable; Physical and mechanical function balance, moisture-proof outstanding, its forming processing function special V, can be easily made into sheet, film, container, flat wire and other packaging plastic products, and low price, so it is widely used in packaging, as plastic packaging materials, its primary defect is poor oxygen resistance.