This article will systematically introduce the related knowledge of blow molding process, including: principle, application, advantages and so on.

What is the blow molding process?

Blow molding process, also known as hollow blow molding process.

Thermoplastic resin by extrusion or injection molding tubular plastic billet, while hot (or heated to the softening state), placed in the open mold, closed the mold immediately in the billet into the compressed air, so that the plastic billet blown and close to the mold wall, after cooling demoulding, you can complete the production of a variety of blow molding products. It is a method of forming hollow products by blowing and expanding hot melt embryos enclosed in molds under gas pressure.

What are the products of blow molding process?

The main field of application is in industry. But with the continuous improvement of technology, the field of application of blow molding technology is more and more extensive.

Industry is mainly different capacity, shape, use of water tanks, storage tanks and so on. Such as: common plastic blow tank, different shapes of horizontal and vertical buckets, special purpose IBC bucket, double ring bucket, plastic tray and so on.

Solar energy in daily life, small bottles for medicine, cosmetics, drinks, plastic toys, etc.; Roadblocks and cones used for public transportation services; Portable toilets, septic tanks and other kayaks and floating docks used in Marine facilities for environmental protection services; Fuel tanks, car shock absorbers, seat backs, brackets, armrests and headrest cover can also be produced by blow molding.

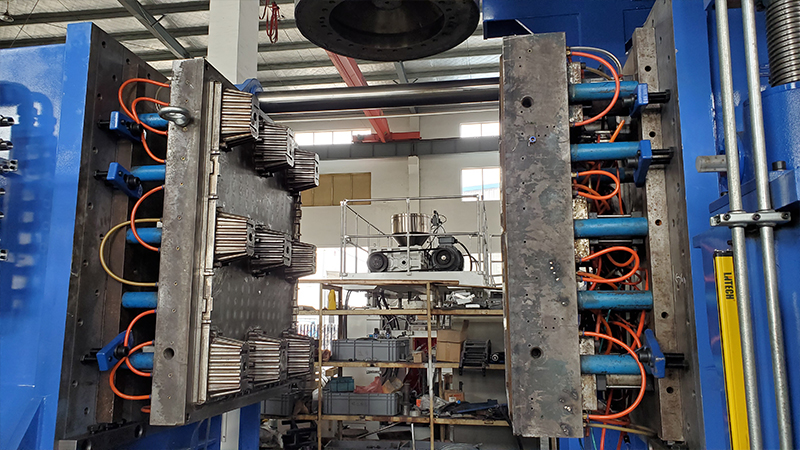

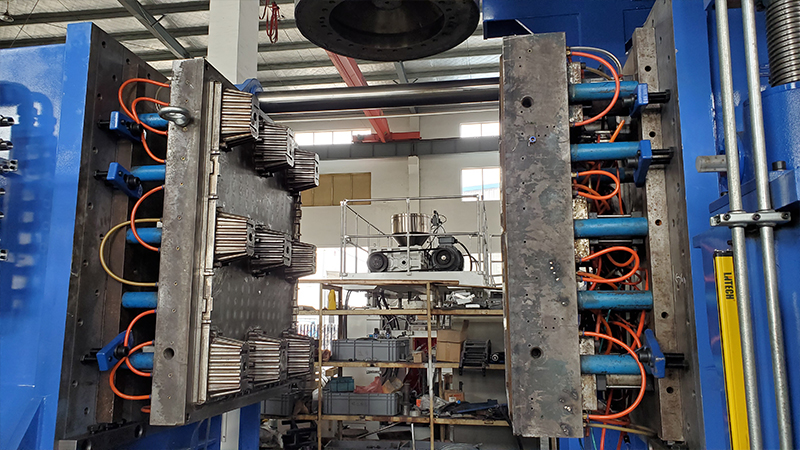

HUAN Plastic Machinery Factory produces 0-1000L water tank blow molding machine. At the same time, we also provide different products of blow molding machine customization service. We can provide customized services according to different customer needs, different regional standards and different technical parameters of blow molding products.

What are the advantages of blow molding?

As for the blow molding process itself:

1. Fast forming speed and high production efficiency

HUAN Blow molding machine can produce an average of 18-20 large capacity multi-layer water tanks per hour

2. The process flow of blow molding machine can ensure the uniform wall thickness of blow molding products, and the wall thickness of products is more stable and uniform than that of products produced by other molding methods

3. Low pressure molding, improve dimensional stability, chemical corrosion resistance and high temperature performance

4. The blow molding process has low requirements for raw materials, and the raw materials that meet the requirements can be recycled; Low energy consumption in the production process, so more environmental protection, energy saving, cost saving

In the design and production of the blow molding machine, the HUAN Plastics Machine uses electromagnetic induction heater for the die head of the blow molding machine and extruder, which can save 40 to 50 percent of energy. Meanwhile, the clamping system uses servo motor, which can save 40 percent of energy.

5. The blow molding process is simple to operate. In addition, the production process is becoming more and more intelligent, which does not require a lot of labor.

In addition, blow molding products, quality assurance, product performance is good.

With extrusion resistance, wear resistance, corrosion resistance, low temperature resistance, impact resistance, good air tightness, long service life and other advantages

Blow molding process said here, if you want to produce related blow molding products, this plastic molding process is a good long-term choice; If you want to choose blow molding products, then the product produced by blow molding technology is also a good choice.