IBC tonnage refers to the IBC medium bulk container. It is an essential tool for modern storage and transportation of liquid products. The container is composed of an inner container and a metal frame. The inner container is blow-molded with high molecular weight and high density polyethylene, which has high strength, corrosion resistance and good hygiene.

Advantages of IBC tank :

Using container packaging can greatly reduce production, storage, transportation, and operation costs. Save a lot of manpower and material resources. Compared with traditional packaging, storage can save 35% space, and forklift operations can be used for loading and unloading, reducing many troubles of manual handling. Filling: 1 ton barrel = 5 200L barrels. During the filling process, the trouble of repeated operations is reduced, and at the same time, the waste of material leakage and spillage during the filling process is avoided.

In summary, the container barrel is easy to use, economical and durable. With the development of internationalization, the container barrel has gradually become the mainstream product of liquid packaging. It can contain Class II and Class III dangerous goods. The maximum liquid density of Class II dangerous goods is 1.5g/cm3, and the liquid density of Class III dangerous goods is 1.8g/cm3. The product structure is reasonable, firm and sturdy, can be directly loaded and unloaded with a forklift, and can be stacked and stored. The bottom of the product is equipped with a drain valve, which is convenient, rapid, thorough, safe, easy to clean, and can be used in multiple cycles, which saves energy and is conducive to environmental protection.

IBC barrels have the following 3 specifications:

820L, 1000L, 1200L

820L IBC Tank specifications:

Model | Capacity(L) | Weight(kg) | Size(mm) | Max. density of contents | Pallet Type |

820 | 880 | 58 | 1200x1000x1000 | 1.9 | All-steel tray |

The 820L composite medium-sized bulk container is designed to adapt to the packaging, storage and transportation of various liquid products in accordance with international maritime dangerous regulations, relevant national laws and regulations and industry standards. This product is designed with good hygiene, comprehensive mechanical physical properties and connotative mechanical principles. Formed, the product ensures the corrosion resistance to acid, alkali, oil and other liquids, and has the advantages of transportation, convenient use, and safe storage. It is suitable for road, rail, and water (sea) transportation, and is more suitable for standard container export. The product can be widely used in petrochemicals, dyes, intermediates, pesticides, brewing, daily chemicals, beverages and other liquid manufacturing industries, as the storage and transportation packaging of Class II and below dangerous goods and ordinary liquid products.

The 820L composite medium-sized bulk container liner is made of ultra-high molecular weight high-density polyethylene (HWHDPE) once blow molding. The axial and radial wall thickness control is used to make the wall thickness of the container liner at the symmetrical part relatively uniform. An anti-ultraviolet agent is added to the HWHDPE raw material to prevent the container liner from aging. There is a liquid level scale line on the side of the container to facilitate filling. The discharge valve is made of high-density polyethylene (HDPE) and polypropylene (PP), and is connected with the container liner with a screw thread. It uses EPDM or fluorine rubber (FPM) to adapt to the resistance of various liquid products. Corrosion performance. The valve handle is equipped with safety screws to prevent accidental opening. The valve outlet is equipped with an inner cover and a sealing ring, and is fixed with a threaded cover on the outside as a secondary seal of the valve to prevent valve leakage. The upper part of the container liner is a filling port with a diameter of 140MM, which is connected to the filling port cap with a thread of 160MM in diameter, and is sealed with a EPDM or FPM sealing ring. The filling mouth cover is equipped with a sampling cover middle cover and an anti-theft cover to facilitate sampling. The filling mouth cover and the sampling cover middle cover are sealed with EPDM or FPM seals. The anti-theft cover uses a one-time buckle and tear-proof anti-theft cover. A high-efficiency pressure reducing valve is installed in the lid to release the gas volatilized by the liquid product or the pressure change caused by the change of the air volume in the upper part of the container liner when the container is expanded and contracted. The pressure reducing valve and the middle cover of the sampling cover are tightly sealed with a taper. The inner container cannot withstand internal pressure. In the selection of materials for each part, both hygiene and corrosion resistance to acids, alkalis, oils and other liquids are taken into account.

The outer frame of the 820L composite medium-sized bulk container adopts a hot-dip galvanized welded pipe with a diameter of 18MM to press the solder joints and then use a DC gantry spot welder to weld and bend it. Arranged at intervals to achieve the maximum endurance. The bottom plate of the bulk container is formed by pressing and welding of hot-dip galvanized deep-drawing plate (ST12). In the design of the shape, a number of reinforcing ribs are pressed in full consideration of the load-bearing capacity. The bottom plates of the outer frame are connected by galvanized bolts, with spring washers, and a label is installed above the discharge valve to facilitate the pasting of the product label. The label is also equipped with a composite medium-sized bulk container identification and instructions for use. Plastic corner protectors are installed on the four bottom corners of the lower part to protect the plastic inner liner.

The 820L composite medium bulk container can only be lifted from the bottom into the fork. It cannot be lifted or the top is lifted. It can be lifted in four directions. It can be stacked for storage and transportation. When the density of the product is less than 1.4 in static stacking, it can be stacked in four layers, when the density is greater than 1.4, it can be stacked in three layers. When it is dynamically stacked in transportation, it can be stacked when the product density is less than 1.4. It can only be transported in a single layer when the density is greater than 1.4.

Main parameters of 820L composite medium bulk container:

IBC Type Code: UN31HA1 Dangerous Goods Packing Class: Class II

Hydraulic test pressure: 100kpa Air tightness test pressure: 20 kpa

Base plate material: ST12 Frame material: spcc

Product warranty period: one year

820L maximum allowable total mass 1612kg maximum allowable total mass 1962kg

Maximum allowable total mass 2344kg

1000L IBC tank specification:

Model | Capacity(L) | Weight(kg) | Size(mm) | density | Pallet type |

1000 | 1058 | 56 | 1200x1000x1135 | 1.9 | Steel |

1000 | 1058 | 62 | 1200x1000x1135 | 1.9 | Steel |

The 1000L composite medium-sized bulk container is designed to adapt to the packaging, storage and transportation of various liquid products in accordance with the international maritime dangerous regulations, relevant national laws and regulations and industry standards. The product is designed with good hygiene, comprehensive mechanical physical properties and connotative mechanical principles. Formed, the product ensures corrosion resistance to acids, alkalis, oils and other liquids, and has the advantages of transportation, convenient use, and safe storage. It is suitable for road, rail, and water (sea) transportation, and is more suitable for standard container export. The product can be widely used in petrochemicals, dyes, intermediates, pesticides, brewing, daily chemicals, beverages and other liquid manufacturing industries, as the storage and transportation packaging of Class II and below dangerous goods and ordinary liquid products.

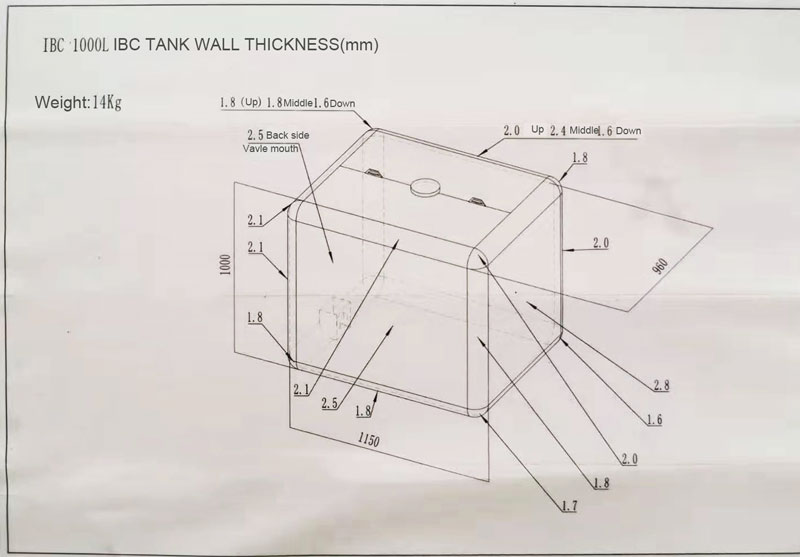

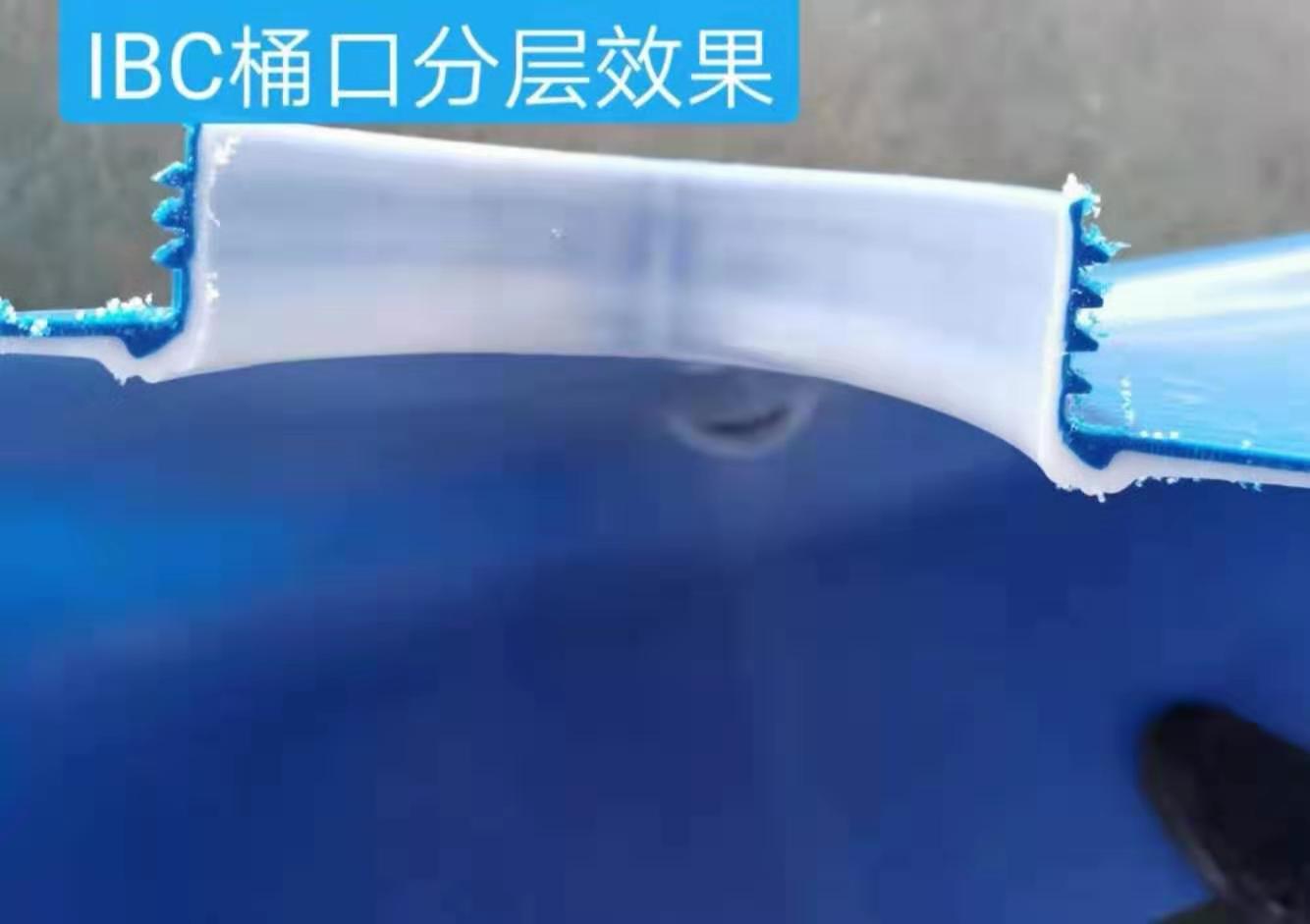

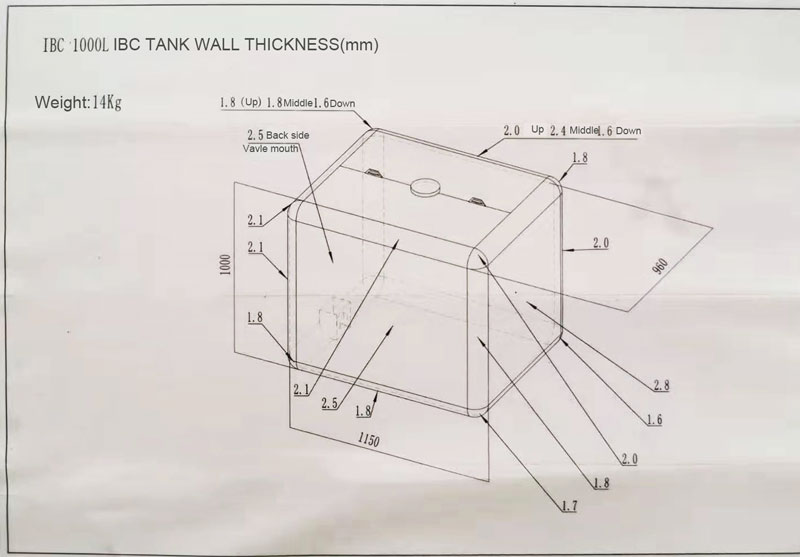

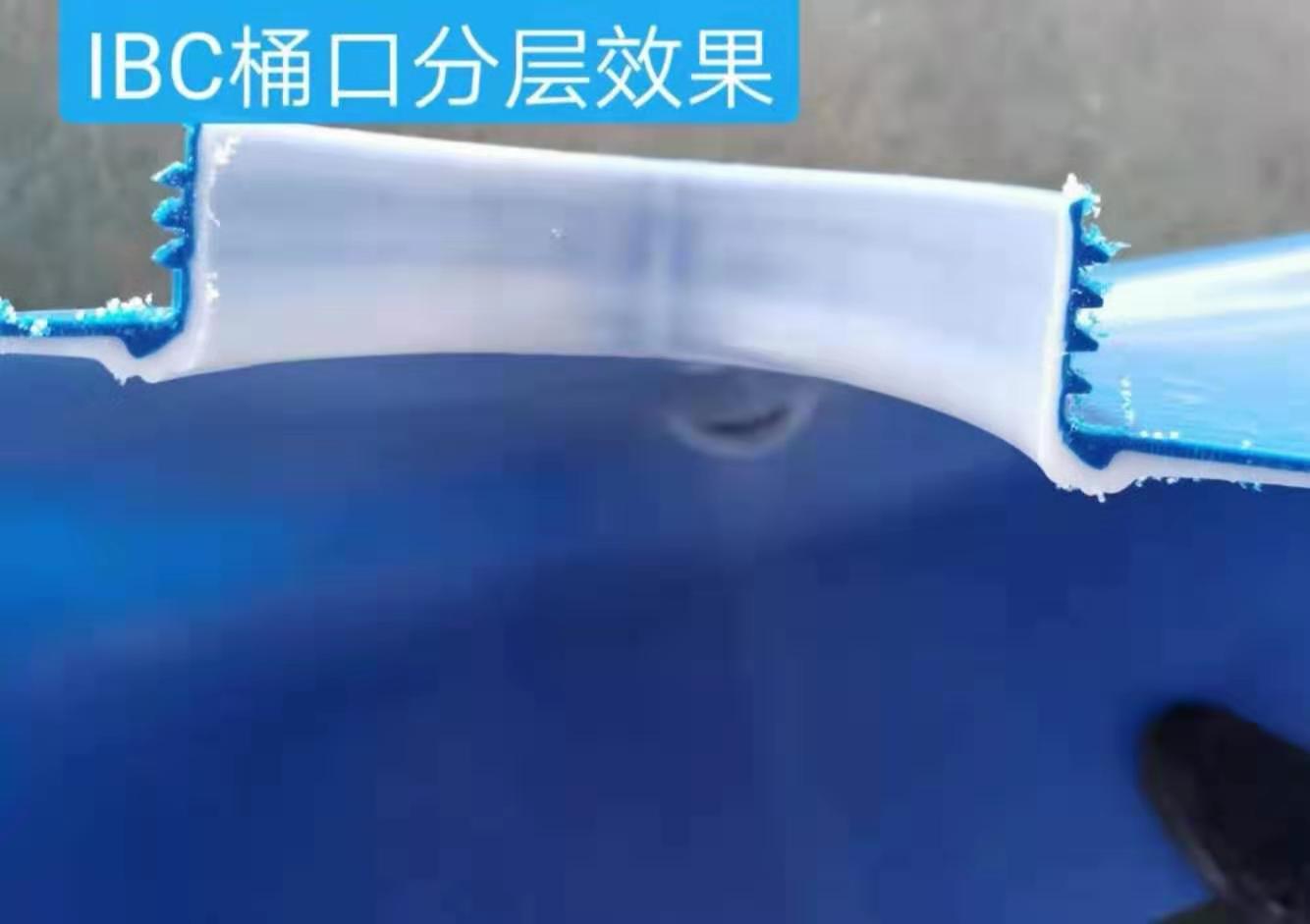

The 1000L composite medium-sized bulk container liner is made of ultra-high molecular weight high-density polyethylene (HWHDPE) at one time blow molding. The axial and radial wall thickness control is used to make the wall thickness of the container liner at the symmetrical part relatively uniform. An anti-ultraviolet agent is added to the HWHDPE raw material to prevent the container liner from aging. There is a liquid level scale line on the side of the container to facilitate filling. The discharge valve is made of high-density polyethylene (HDPE) and polypropylene (PP), and is connected with the container liner with a screw thread. It uses EPDM or fluorine rubber (FPM) to adapt to the resistance of various liquid products. Corrosion performance. The valve handle is equipped with safety screws to prevent accidental opening. The valve outlet is equipped with an inner cover and a sealing ring, and is fixed with a threaded cover on the outside as a secondary seal of the valve to prevent valve leakage. The upper part of the container liner is a filling port with a diameter of 140MM, which is connected to the filling port cap with a thread of 160MM in diameter, and is sealed with a EPDM or FPM sealing ring. The filling mouth cover is equipped with a sampling cover middle cover and an anti-theft cover to facilitate sampling. The filling mouth cover and the sampling cover middle cover are sealed with EPDM or FPM seals. The anti-theft cover uses a one-time buckle and tear-proof anti-theft cover. A high-efficiency pressure reducing valve is installed in the lid to release the gas volatilized by the liquid product or the pressure change caused by the change of the air volume in the upper part of the container liner when the container is expanded and contracted. The pressure reducing valve and the middle cover of the sampling cover are tightly sealed with a taper. The inner container cannot withstand internal pressure. In the selection of materials for each part, both hygiene and corrosion resistance to acids, alkalis, oils and other liquids are taken into account.

The outer frame of the 1000L composite medium-sized bulk container is made of hot-dip galvanized welded pipes with a diameter of 18MM to press the solder joints and then welded and bent with a DC gantry spot welder. The arrangement of the horizontal and vertical pipes fully takes into account the stress conditions of each part, and uses different Arranged at intervals to achieve maximum bearing capacity. The bottom plate of the bulk container is formed by pressing and welding of hot-dip galvanized deep-drawing plate (ST12). In the design of the shape, a number of reinforcing ribs are pressed in full consideration of the load-bearing capacity. The bottom plates of the outer frame are connected by galvanized bolts, with spring washers, and a label is installed above the discharge valve to facilitate the pasting of the product label. The label is also equipped with a composite medium-sized bulk container identification and instructions for use. Plastic corner protectors are installed on the four bottom corners of the lower part to protect the plastic inner liner.

The 1000L composite medium bulk container can only be lifted from the bottom into the fork, not to be lifted or the top to be lifted, and it can be lifted into the fork in four directions. It can be stacked for storage and transportation. When the density of the product is less than 1.4 in static stacking, it can be stacked in four layers, when the density is greater than 1.4, it can be stacked in three layers, and when it is dynamically stacked in transportation, it can be stacked when the density of the product in transportation is less than 1.4. Two-layer yard, when the density is greater than 1.4, it can only be transported in a single layer[2].

Main parameters of 1000L composite medium bulk container:

IBC Type Code: UN31HA1 Dangerous Goods Packing Class: Class II

Hydraulic test pressure: 100kpa Air tightness test pressure: 20 kpa

Base plate material: ST12 Frame material: spcc

Product warranty period: one year

Maximum allowable total mass 1612kg

The maximum allowable total mass of 1000L is 1962kg

Maximum allowable total mass 2344kg

Discharge valve diameter: 50 mm Filling port diameter: 140mm

Relative density of the largest filling medium: 1.9 Liner material: UHMWPE

The minimum thickness of the inner tank: ﹥1.2mm Valve material: HDPE PP

Sealing material: FPM/EPDM Applicable ambient temperature: -18~+55℃

Dimensions: 1000 (length × width × height): 1200 × 1000 × 1135 (mm)

1200L type IBC ton barrel

CD1200L composite medium-sized bulk container is designed to adapt to the packaging, storage and transportation of various liquid products in accordance with international maritime dangerous regulations, relevant national laws, regulations and industry standards. The product is designed with good hygiene, comprehensive mechanical physical properties and connotative mechanical principles. Formed, the product ensures corrosion resistance to acids, alkalis, oils and other liquids, and has the advantages of transportation, convenient use, and safe storage. It is suitable for road, rail, and water (sea) transportation, and is more suitable for standard container export. The product can be widely used in petrochemicals, dyes, intermediates, pesticides, brewing, daily chemicals, beverages and other liquid manufacturing industries, as the storage and transportation packaging of Class II and below dangerous goods and ordinary liquid products.

CD1200L composite medium-sized bulk container liner is made of ultra-high molecular weight high-density polyethylene (HWHDPE) once blow molding, using axial and radial wall thickness control to make the wall thickness of the container liner at the symmetrical part relatively uniform. An anti-ultraviolet agent is added to the HWHDPE raw material to prevent the container liner from aging. There is a liquid level scale line on the side of the container to facilitate filling. The discharge valve is made of high-density polyethylene (HDPE) and polypropylene (PP), and is connected with the container liner with a screw thread. It uses EPDM or fluorine rubber (FPM) to adapt to the resistance of various liquid products. Corrosion performance. The valve handle is equipped with safety screws to prevent accidental opening. The valve outlet is equipped with an inner cover and a sealing ring, and is fixed with a threaded cover on the outside as a secondary seal of the valve to prevent valve leakage. The upper part of the container liner is a filling port with a diameter of 140MM, which is connected to the filling port cap with a thread of 160MM in diameter, and is sealed with a EPDM or FPM sealing ring. The filling mouth cover is equipped with a sampling cover middle cover and an anti-theft cover to facilitate sampling. The filling mouth cover and the sampling cover middle cover are sealed with EPDM or FPM seals. The anti-theft cover uses a one-time buckle and tear-proof anti-theft cover. A high-efficiency pressure reducing valve is installed in the lid to release the gas volatilized by the liquid product or the pressure change caused by the change of the air volume in the upper part of the container liner when the container is expanded and contracted. The pressure reducing valve and the middle cover of the sampling cover are tightly sealed with a taper. The inner container cannot withstand internal pressure. In the selection of materials for each part, both hygiene and corrosion resistance to acids, alkalis, oils and other liquids are taken into account.

The outer frame of the CD1200L composite medium-sized bulk container is made of hot-dip galvanized welded pipes with a diameter of 18MM. After pressing the solder joints, they are welded and bent by a DC gantry spot welder. Arranged at intervals to achieve the maximum endurance. The bottom plate of the bulk container is formed by pressing and welding of hot-dip galvanized deep-drawing plate (ST12). In the design of the shape, a number of reinforcing ribs are pressed in full consideration of the load-bearing capacity. The bottom plates of the outer frame are connected by galvanized bolts, with spring washers, and a label is installed above the discharge valve to facilitate the pasting of the product label. The label is also equipped with a composite medium-sized bulk container identification and instructions for use. Plastic corner protectors are installed on the four bottom corners of the lower part to protect the plastic inner liner.

CD1200L composite medium-sized bulk containers can only be lifted from the bottom into the fork, not to be lifted or the top to be lifted, and can be moved into the fork in four directions. It can be stacked for storage and transportation. When the density of the product is less than 1.4 in static stacking, it can be stacked in four layers, when the density is greater than 1.4, it can be stacked in three layers, and when it is dynamically stacked in transportation, it can be stacked when the density of the product in transportation is less than 1.4. Two-layer yard, only single-layer transportation when the density is greater than 1.4.

Model | Capacity(L) | Weight(kg) | Size(mm) | Density | Pallet type |

1200 | 1360 | 64±2 | 1200x1000x1350 | 1.9 | Steel |