IBC Tank Production 101: Your Complete Guide

IBC tank( Intermediate medium bulk container)It is a necessary tool for modern storage and transportation of liquid products in various industries. The container is composed of an inner container and a metal frame. The inner container is blow-molded with high molecular weight high-density polyethylene, which has high strength, corrosion resistance and good hygiene.

IBC tank can be widely used in chemical, pharmaceutical, food raw materials, daily chemical, petrochemical and other industries, suitable for a variety of fine chemical, medical, daily chemical, petrochemical powder and liquid storage and transportation, can also be used for heat storage.

Influenced by the development of the global chemical industry, the demand of the IBC tank market continues to rise, and the development prospect of the industry is good. In terms of production, IBC industry profit is higher, attracting many enterprises layout. This article will take you through the whole production line of IBC tank.

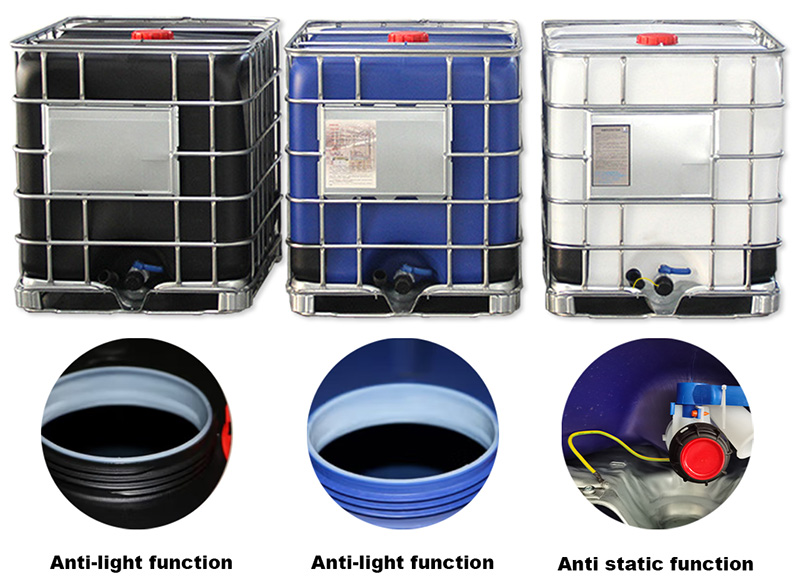

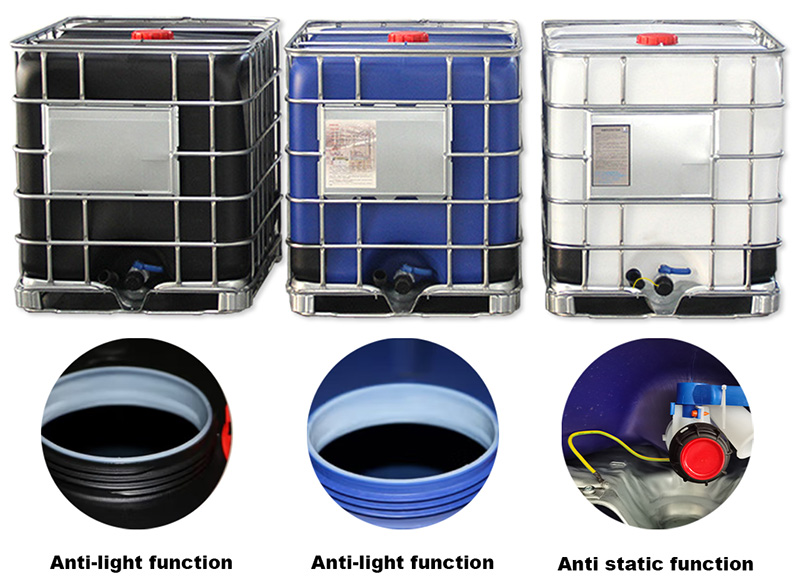

Types of IBC tanks:

1. Normal type: Suitable for II, III hazardous liquids and normal non-hazardous liquids package and transportation

2. Anti-static type: filling nonflammable liquid, II A type flammable liquid II B flammable (min. ignition energy more than 0.2mJ), can use in explosion-proof Zone 1 & Zone 2)

3. Anti-light type: Suitable for filling liquids which is easy to solidify,polymerize and decompose under light

4. Food type: suitable for food liquid filling and transportation

5. Electronic type: suitable for electronic chemicals, no dust no pollution during production

Common components of IBC tanks

1. inner IBC tank

2. Metal frame (See the table below for details)

No. | Name | Quantity |

1 | top tube | 1 pc |

2 | horizontal tube | 5 pcs |

3 | vertical tube (no hole) | 16 pcs |

4 | vertical tube (with hole) | 4 pcs |

3. Metal pallet

No. | Name | Quantity |

1 | bottom tray | 1 pc |

2 | bottom foot corner | 4 pcs |

3 | middle foot corner | 1 pc |

4 | middle beam | 1 pc |

5 | Bottom tube | 1 pc |

4. Plastic parts

1 pc cap,1 pc valve,4 pcs bottom protection foots,1 pc plastic cover,1pc pipe

Advantages of IBC tank design

1. Large-capacity packaging, each IBC tank can fill one ton of water

2. The liner tank adopts hdpe materials, high strength, corrosion resistance, good hygiene, long service life, safe and reliable;

3. Save space, IBC tank stacks up to 25% less space than a traditional 200L hdpe drum, up to four layers can be stacked, greatly reducing the cost of storage and transportation;

4. IBC tank with reasonable structure, firm, with steel tray, can use forklift or manual hydraulic truck loading and unloading transportation, greatly reduce the labor intensity of workers;

5. The container has its own drain valve, which is reliable in draining. The self-weight of the liquid can be used for natural drainage, and the special geometric design makes the drainage more thorough, rapid and safe;

6. The external dimensions comply with ISO container design standards, and are especially suitable for sea container transportation. A 20-foot container can carry 18-20 pieces 1,000-liter containers, which greatly reduces transportation costs.

7. There is a volume scale on the inner barrel, the user can clearly see the height of the liquid in the container, and calculate the volume and weight in the container without repeated measurement, which shortens the management time.

8. Widely used in the packaging of various chemical dangerous liquids such as Class II and III, the density of the filled liquid can reach up to 2.1, and a high-efficiency pressure reducing valve is installed in the lid, so the storage and transportation process is safe and reliable;

9. IBC tank adopts a combined structure design, which is convenient for component replacement, prolongs the service life and reduces the cost of use;

What materials are needed for the production of IBC tanks?

IBC tanks are an essential tool for storage and transportation of liquid products. The barrel assembly consists of an inner container and a metal frame. The liner is made of high-molecular-weight high-density polyethylene blow molding, which has high strength, corrosion resistance and good sanitation.

The main raw material used in IBC barrels is 4570UV high-density polyethylene (HDPE) or 644 low-density polyethylene, which is a tasteless, odorless, non-toxic granular product. It has good heat resistance and cold resistance, good hardness, tensile strength, electrical insulation and toughness, and good chemical stability. IBC barrels are almost insoluble in any organic solvents at room temperature, resistant to various acids, alkalis, and salt solutions, have excellent resistance to environmental stress cracking and thermal stress cracking, high surface hardness, and good dimensional stability. The steel used for the frame is processed by automatic pipe bending equipment, and the frame and pallet adopt a specific patented design. Reasonable structure, good reliability, excellent anti-accidental drop and heavy-duty container stacking performance, and can meet the shipping requirements of similar dangerous chemicals. The container is equipped with an adjustable ball valve for convenient and reliable draining.

The valve body of the IBC barrel is made of HDPE, and the ball is made of PP, which has good chemical compatibility. Valve seals are EPDM, but other materials such as ETFE, polyethylene, and nitrile are also available. The thread of the valve exhaust port is the standard thread S606, and adapters are provided for customers to choose.

Name | Reference figure | Material Science | Specification and size(millimeter) | Thickness (millimeter) | Processing technology |

Bottom floor |

| DX53D | 1200x1000mm | 1 | Stamping |

Beam |

| DX51D | 1006x160x80mm | 1.8 | Stamping |

Bottom corner |

| DX51D | 180x80xR90mm | 1.4 | Stamping

|

What are the main steps in the extrusion blow molding process of IBC tanks?

1. Use the extrusion blow molding machine to obtain a certain size of preform through the machine head, and then extrude the parison, then blow molding, cooling, and demoulding.

2. After the product is extruded, it is clamped into the closed mold, and the parison is blown into the shape of the mold by the blow molding system until it is cooled and set and can be released from the mold.

3. After the product is inflated and formed, the amount of compressed air can be increased, and then the mold jacket can be used to shape the product through cooling water, and finally the mold is demoulded to become an IBC tank.

What should I pay attention to when blow molding IBC totes?

1. The gap between the mold openings for forming tubular blanks should be adjusted evenly before production; the heating and temperature control should make the mold temperature slightly higher than the melt temperature (about 5°C higher);

2. Before and during the production of this product, pay attention to the lubricating oil filling of the sliding part of the mobile mold to keep the sliding part clean and well lubricated;

3. When blow molding the product, the pressure of the compressed air is 0.2-0.7MPa. For thick-walled products, take a smaller pressure value, and for thin-walled and large-scale products, take a larger pressure value;

4. The molten material of the tubular billet for extrusion molding should have a bright surface, no melting mark (line), and uniform wall thickness; when the tubular billet is unevenly discharged or the wall thickness error is large, the gap between the die and die core should be adjusted appropriately . It is required that when the wall thickness of the tubular billet changes regularly in the axial direction, the program control system should be used to control the die core to move up and down, so as to achieve the change of the gap between the die core and the die, and realize the adjustment of the axial wall thickness of the parison;

5. Control the temperature of the circulating water for cooling the forming mold at about 10°C to ensure that the working temperature of the mold is within the range of 20-50°C. If the wall thickness at the clamping mouth of the product is large or there are spots on the surface of the product, it means that the mold temperature is low, and the mold temperature should be increased appropriately (such as reducing the flow rate of the cooling circulating water, which can increase the mold temperature. ).

Quality control and inspection during blow molding process

(1) Understand the process characteristics of raw materials (such as resin grade, density, melt index, rheology, etc.), combine basic theoretical knowledge and blow molding product requirements, and plan the heating, cooling and molding of each section of the extruder, head and mold Process conditions: barrel temperature, die temperature, blowing time.

(2) Familiar with the operating procedures of extrusion blow molding machine. Turn on the main power switch, and put the transfer switch on the control board of the auxiliary machine in the manual position. Turn on the oil pump motor, press the following buttons in order to open the mold", "mold base up", "mold clamping" and "mold base down" to check the function of the hydraulic system. Connect the compressed air source, press the "air nozzle", " Cutter" and other buttons to check the function of the pneumatic system. Press the "Down" button to check whether the air nozzle is aligned with the mold neck. If there is any deviation, adjust the adjustment mechanism. Press the "Air nozzle down" button to check the air nozzle Whether the edge just touches the die orifice.

(3) Turn on the power supply of each heating zone of the barrel and die head, set the temperature, and after heating to the set temperature, keep the temperature constant for 15 minutes. Turn on the switches on the panel of the control box, select the machine working mode as automatic, adjust the timing of each timer, then add the prepared raw materials, start the main machine, and start the automatic bottle blowing operation. Observe the thickness uniformity of the product and the transparency of each part, adjust the extrusion temperature, extrusion speed, and die ring gap until it is qualified.

(4) By adjusting the heating temperature of the die, adjusting the die gap, and constantly observing the changes in the appearance quality and performance of the product until it is adjusted to a perfect state. By changing the air pressure, change the cooling mode, and observe the cooling effect.

Automation in IBC Tank Production

In addition to the IBC tank blow molding process, the other major step is IBC tank metal frame production line.

IBC tank frame automatic production line customized according to customer needs. The whole production line consists of welding, bending forming, locking, stamping and punching and other processes.It has the characteristics of high production efficiency, high yield and labor saving.

The production process includes welding from the galvanized pipe to the frame mesh, bending the outer frame, riveting the two ends of the bending frame, flattening and punching the connection between the bottom tube of the frame and the bottom plate, and partly using steel The foot is welded as the bottom support steel foot of the bottom support. The frame mesh welding machine adopts the intermediate frequency inverter welding resistance controller, which has the advantages of fast welding speed, high current, and good penetration. It is suitable for welding IBC frame mesh galvanized ribbed crescent tubes, galvanized ribbed square tubes, etc. material, and achieve excellent welding strength and appearance of solder joints; the welded mesh can be stacked by manual handling or automatic unloading by manipulators to the mesh stacking trolley and transported to the next process; the welding line uses pneumatic manipulators And the conveyor belt can realize the automatic feeding, reversing, bending, locking, flattening, punching and conveying of the mesh.

Features of IBC ton barrel frame production line:

· The whole machine adopts man-machine interface + PLC programming operation mode to control, with high level of automation

· The overall processing of the equipment frame ensures the accuracy of the equipment, the stability of the operation and the high efficiency

· Use intermediate frequency inverter welding resistance controller, fast welding speed, current stability, good penetration, etc.

· The welding pressure is uniform and consistent to ensure the quality of all solder joints

· Double loading frame design, which can be loaded when the main welding machine is working, improving production efficiency

· Servo hydraulic pressure is adopted, which has the characteristics of fast response, small inertia and high precision

· The entire automated production line can quickly realize the bending, locking and punching of the frame

· Can do diversified non-standard customization according to various stamping shape requirements of customers

Whole solution for IBC tank production

Solution I

Solution II

Solution III

IBC Tank Application

Based on the analysis of the application market of ibc tote, the storage and transportation of chemical products currently occupy the main market, accounting for about 80%.

IBC tank can also be used for the storage of petroleum products, accounting for 15% of this field.

IBC tank can be used in the food field, but they have higher requirements for products, and the current application demand is less, accounting for about 2%.

IBC tank can hold Class II and Class III dangerous goods. There are mainly two types of IBC tank in the current market: 820L and 1000L. Due to the advantages of corrosion resistance, creep resistance, high space utilization rate and convenient use, IBC ton barrels are the mainstream liquid packaging containers in the world, and are mainly used in the packaging of pharmaceuticals, chemicals, coatings and other products.

Advantages of IBC tanks:

1. The steel rod fixed by special screws can easily and quickly replace the inner container.

2. The inner container is blow molded by HDPE, which is anti-ultraviolet, anti-aging and easy to clean.

3. The outer frame is formed by welding hot-dip galvanized steel pipes, and the bottom tray is fixed by non-slip screws (grade 8.8), which is firm and firm.

4. The product marking board outside the frame can mark the company name, product and other instructions that need to be marked, so that customers can fully understand your company's information.

5. The bottom tray is cast with steel plate, which is a four-way entry fork type. Enhances stability and facilitates handling and stacking.

6. The volume scale is cast on the inner tank, and the user can clearly see the liquid level in the container by taking advantage of the transparency of the container.

7. The upper filling port is equipped with a blind cap or a DN150 breather valve threaded cap, and the lower discharge port is equipped with a DN50 ball valve (imported rubber for the seal), which can discharge materials safely and quickly.

In general, the reasons why IBC tank are getting better and better in the current market are as follows:

1. Good stability, the stability of the IBC tank is quite good, because its chassis is supported by a steel pallet, and it is precisely because of this that the IBC tank has better stability. So when you use a IBC tote container to hold things, you don't have to worry about the IBC tank moving.

2.The reuse rate is high, and the IBC tank can be reused many times, so its utilization rate is quite high. Because of this, if you buy a IBC tank, you can use it many times.

How to prolong the service life of IBC tank?

1. Pay attention to the standard operation during the filling and draining process

HDPE tonnage barrels can be used to store most liquids, but before filling, a chemical compatibility test is still required to ensure that the filling material matches the performance of the tonnage barrel. When filling, the liquid should not exceed 60°C. After the filling is completed, a certain buffer space is reserved, and the temperature of the filling material drops to the ambient temperature before tightening the cap.

When draining, open the top filling port cover to prevent negative pressure in the container, unscrew the threaded cover of the discharge valve, tear off the sealing aluminum foil, remove the locking screw, turn the valve wrench clockwise, and start discharging. After the discharge is completed, close the valve, tighten the locking screw, and screw on the sealing cover of the discharge valve and the filling port cover.

2. Avoid collisions during transportation

External shocks and collisions can easily cause the tonnage to be deformed or even damaged. Therefore, the tonnage should be well protected during transportation. The bottom should be lifted during transportation. When using a forklift for loading and unloading, ensure that the fork arm of the forklift is aligned with the fork hole on the tonnage pallet and exceeds the opposite side. After the bottom frame, proceed to lift. The transportation process generally adopts single-layer loading, and the vehicle baffle is higher than or equal to the height of the tonnage. If double-layer loading is required, buffers must be added between the tonnages and tied and fixed to prevent the displacement of the tonnage during transportation.

3. Pay attention to the storage temperature and avoid exposure to the sun

Water stains and dirt will attack the body of the barrel and cause damage to the internal scale. High temperature and exposure to the sun may cause aging and deformation of the barrel. Therefore, tonnage barrels should be stored in a clean, dark, and cool environment, away from flammable and explosive items, and the ambient temperature should be kept between -18°C and 40°C.

4. Reuse needs adequate cleaning

The ton barrel can be reused, but before it is used again, it needs to be fully cleaned and its sealing performance checked to ensure no dirt, no corrosion, and good sealing.

IBC tank case

IBC line case.pdf

IBC line case.pdf

In conclusion, producing IBC tanks requires specialized equipment and expertise. Understanding the production process, material options, and quality control measures is crucial for successful production. As a recap of key points, the production process of IBC tanks involves blow molding machines, extrusion, and welding. The most commonly used materials for IBC tanks are HDPE and steel, although other options such as aluminum and composite materials are also available. Quality control measures include leak testing, impact resistance, and stackability tests.

Overall, investing in the right equipment and working with experienced manufacturers is key to ensuring efficient and high-quality IBC tank production. At [Company Name], we specialize in IBC tank production and offer a range of options to meet our clients' unique needs. We believe in using the latest technology and adhering to the highest quality standards to deliver the best results. If you're interested in learning more about our IBC tank production services or have any questions, please don't hesitate to contact us. We look forward to working with you!