WHAT is IBC ?

IBC stands for “Intermediate Bulk Container.” Let’s break that down a bit. Intermediate – IBCs are designed for shipping and storing products and ingredients, they aren’t meant to be a container for the end-user. Bulk – One 1000L IBC can store as much material as ten standard drums, making wholesale IBC totes and IBCs truly the most effective bulk container. Container – Wholesale IBC totes are incredibly economical and efficient as storage containers. They stack on top of one another very well, they can contain up to 1000 L. they’re reusable, and they’re available in a variety of materials.

| Products Name | Material Grade | Description | Spec. mm | Length mm |

| IBC Gi structure | DX51D /120G | Square vertical bar 3 star | 16*16*0.9 | 5140+/-5 |

| Square horizontal bar 3 star | 16*16*0.9 | 4230+/-5 |

| Horizontal top round tail bar | 18*15*1.2 | 4175+/-5 |

| Round top cross bar | 19*1.0 | 4120+/5 |

| Round base ring tube | 19*1.0 | 4120+/-5 |

| Square tube | 18*18*1.0 | 1155-4220 |

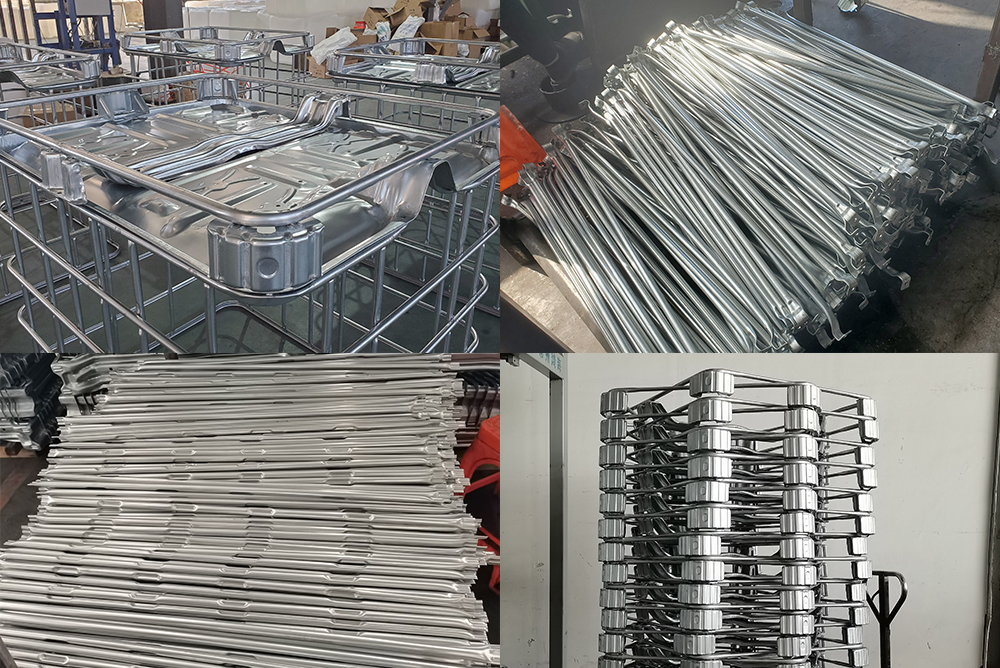

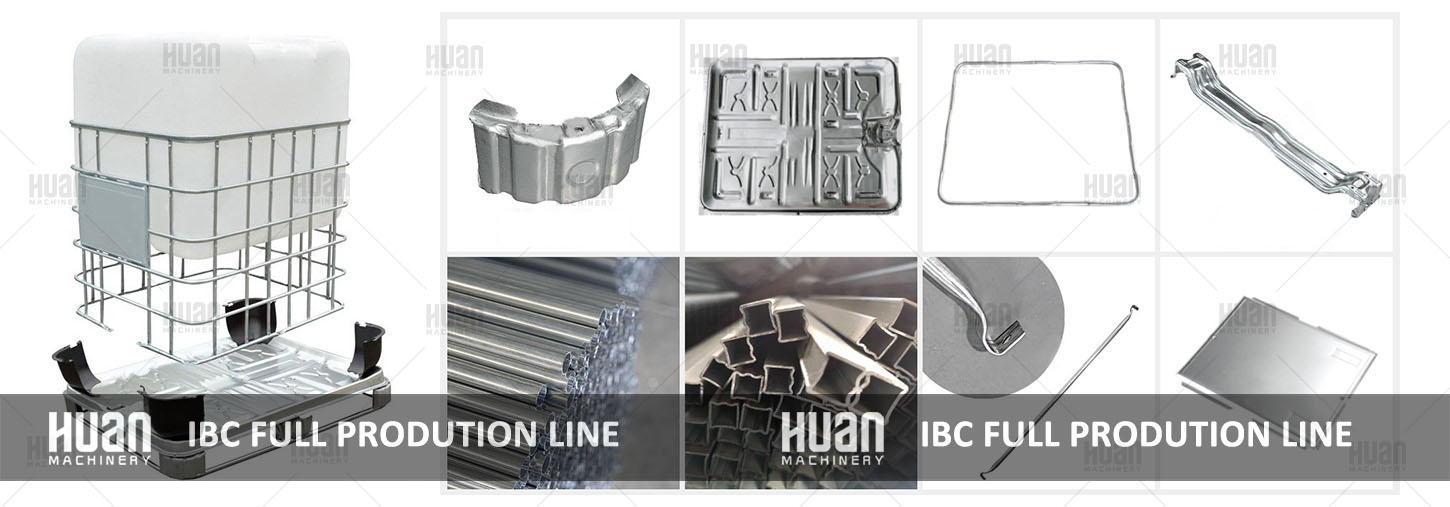

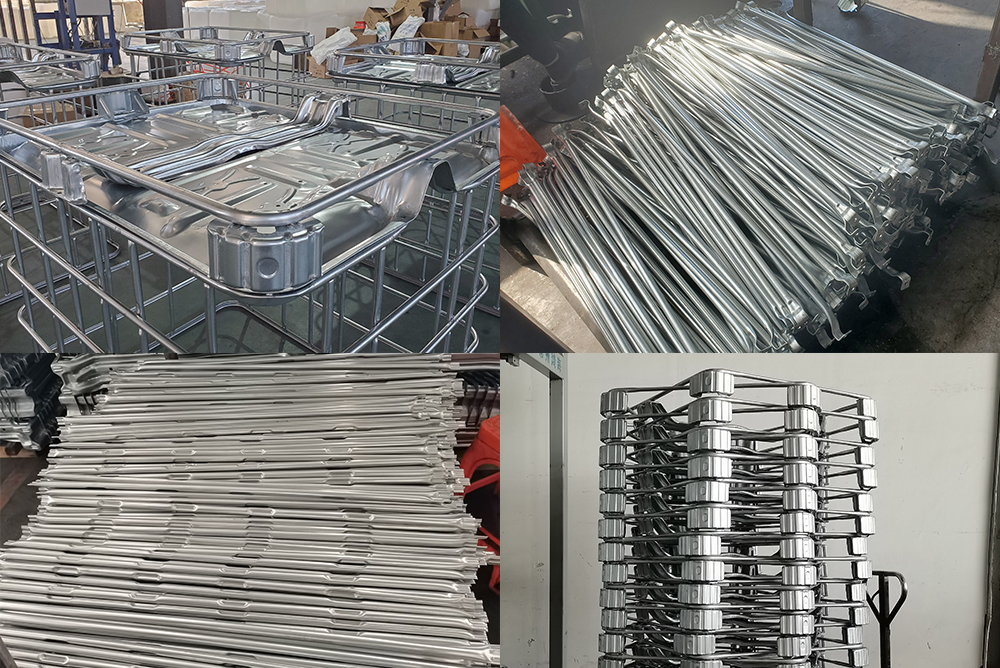

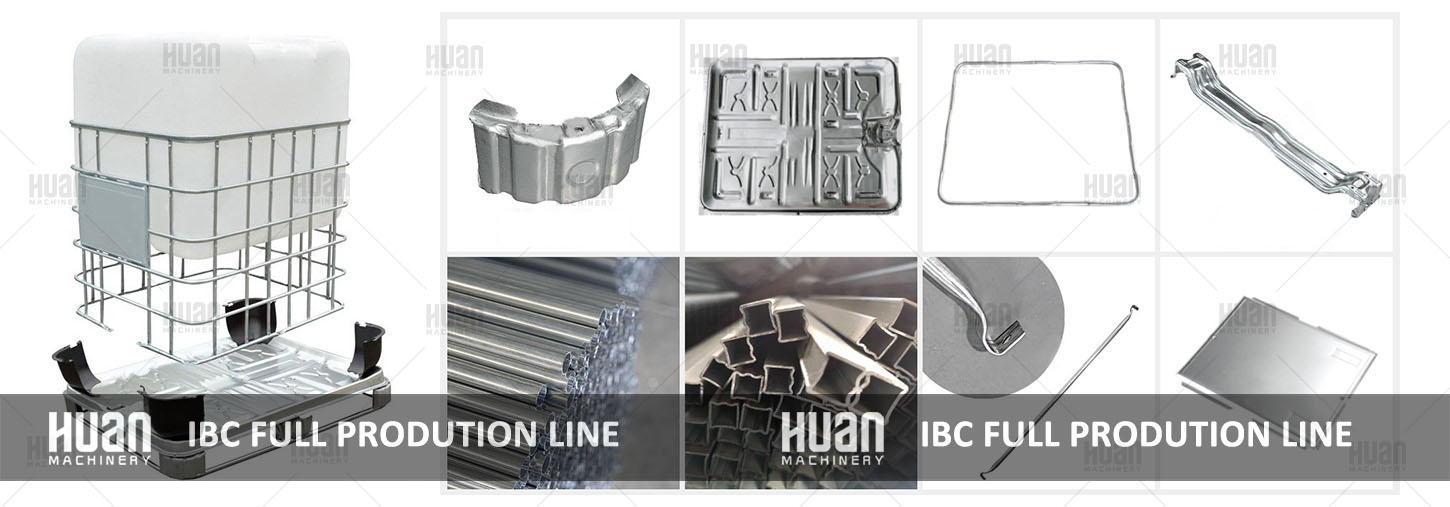

Product Display

Internediate Bulk Container Tank Structure

Specification:

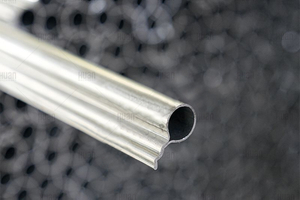

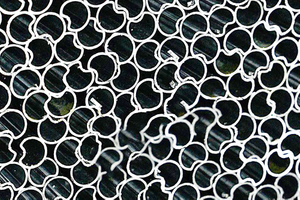

We weld pre-galvanized steel coil of accurate thickness as 0.8mm or 0.9mm or 1.0mm into square section long tubing, cutting them into different short lengths according to end usage requirement.

Surface Treatment:

Per varieties of welding location requirement, we dry and shine the surface with light oil to ensure long-term purpose of anti-rust as long as one year.

Ends Processing:

waged the ends of long tubing or expend the other end to ensure they can insert each other tightly.

Professional Processing on vertical lengths tubing: the whole fabricated process are cutting the long tubes into demanded short length and punch tubing body with certain depth caulks, meanwhile, flat the two ends of each piece with nipples for easy welding process

Type of Tubing:

With long-term experience more than ten years, we can make finished tubing we called steel frame joint bars not only by square tubing, as well as round tubing. Different types of tubes depends on specific requirement from customer.

Service we Provide:

Service A: we provide steel square and round tubes as semi-goods including every part of the IBC, customer need to make deep processing ( cutting, welding, waging, punching etc. ), then assemble it.

Service B: we provide finished material including (Square Vertical Bar 2 star, Square Horizontal Bar 2 star, Horizontal Top Round Tail Bar, Round Top Cross Bar ), well processed after cutting, welding, waging , punching etc., customer only need to assemble it.

Service C: we provide finished IBC,customer can use it directly.