The IBC market is growing rapidly, with a market share of over 60%, and will continue to be a leader and driver of the major trends in liquid packaging.

IBC tank feature:

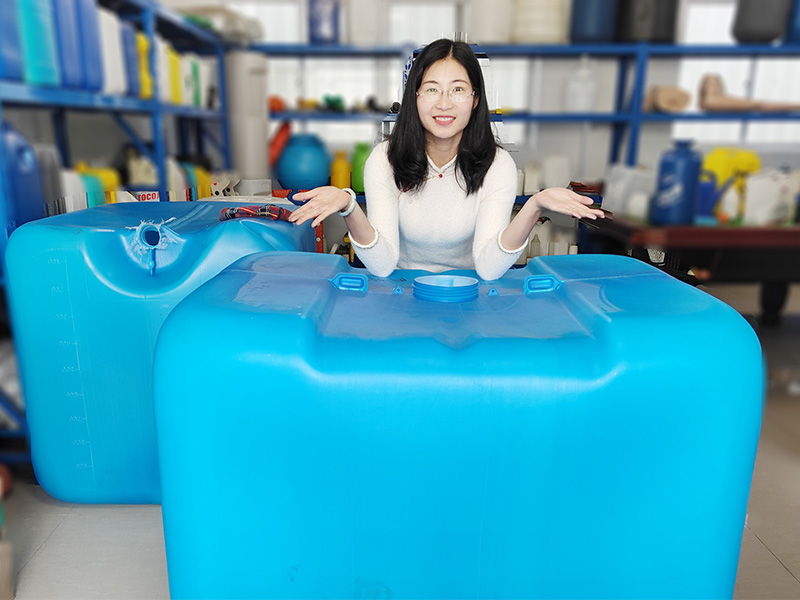

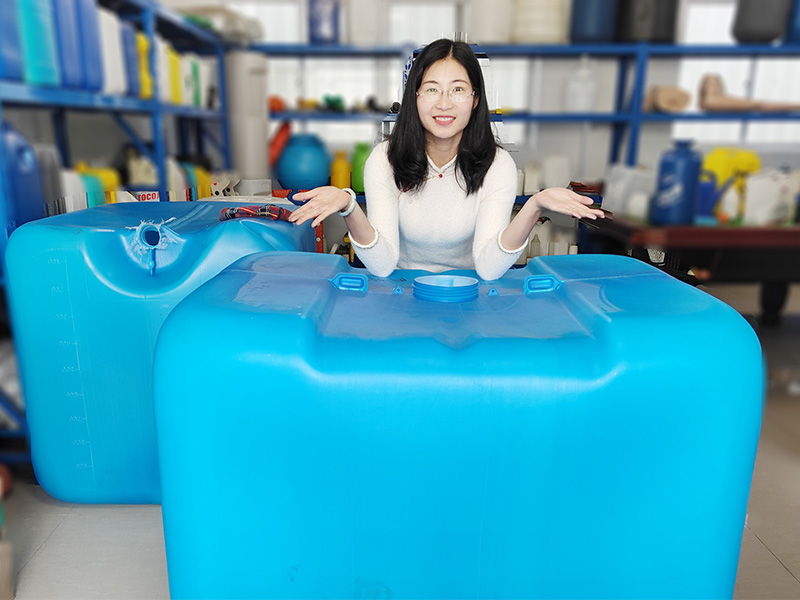

1. It's safer. Whether in product design, or in product production, safety has become the primary feature of IBC plastic container. HDPE (high density polyethylene) is used as the liner, and has a rigid frame of IBC plastic container, higher strength, better chemical resistance, can contain up to 2.2 liquid specific gravity, widely suitable for class II and III hazardous chemicals packaging, transportation and storage.

2. It's more economical. Cost reduction is not only reflected in the reduction of product prices, but also reflected in the entire packaging process of manpower and material resources savings. Either on the stack space (can save 35% of the space), loading and unloading (forklift convenient loading and unloading, greatly reduces the manual handling trouble), transportation (the size of the designed for container transport, especially suitable for various kinds of container transport), use (for up to three years of life, can use repeatedly), IBC container barrels of plastic have greatly reduced the cost, It is your most economical packing choice.

3. Be greener. Good chemical resistance and long service life make IBC plastic container can be used repeatedly, and each part can be recycled, which make it more environmentally friendly, and become a new generation of liquid packaging container.

4. Be professional. The combined design enables each component to be professionally produced and can be replaced at any time. A variety of optional components greatly increase the individuality of the container to meet customers' ever-changing requirements. ISO9001-2000 quality system certification, UN certificate, ship inspection certificate and food hygiene license provide the most professional transportation guarantee for IBC plastic container.

IBC tank advantage:

1, large capacity packaging, each can fill a ton of weight (take 1000 liters as an example);

2, the liner adopts high molecular weight high-density low pressure polyethylene, high strength, corrosion resistance, good hygiene, long service life, safe and reliable;

3, save space, increase the space utilization rate by more than 25% (200 liters plastic bucket), and can be stacked, the highest can be stacked four layers, greatly reducing the storage and transportation costs;

4, reasonable structure, firm, with shovel plate, can use forklift or manual hydraulic truck loading and unloading transport, greatly reduce the labor intensity of workers;

5, the container comes with a drainage valve, drainage is reliable. Can use the weight of the liquid natural drainage, the special geometric design makes the drainage more thorough, rapid and safe;

6, the dimensions conform to the ISO container design standard, in line with international standards, especially suitable for shipping containers, 20 feet of container can be loaded 1000 liters of 18-20 containers, greatly reduce the transportation cost.

7. Easy to manage. The inner barrel is cast with volume scale, the user can take advantage of the transparent characteristics of the container, clearly see the height of the liquid inside the container, very easy to calculate the volume and weight of the container, without the need for repeated measurement, shorten the management time.

8, a wide range of packaging. Widely used in class Ⅱ and Ⅲ and other types of dangerous chemical liquid packaging, filling liquid density up to 2.1;

9. High efficiency pressure reducing valve is installed in the barrel cover, safe and reliable storage and transportation process;

10, the use of combined structure design, component replacement is convenient, prolong the service life, reduce the use cost;

11, authoritative certification support, can obtain the product UN certificate and food hygiene license, specially used for the remote sea transportation of dangerous goods.

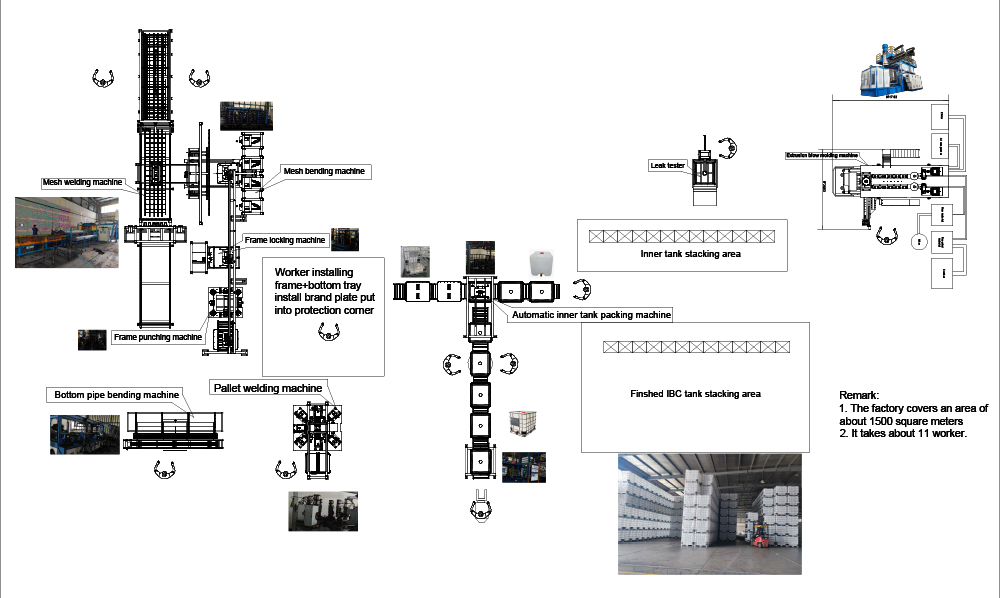

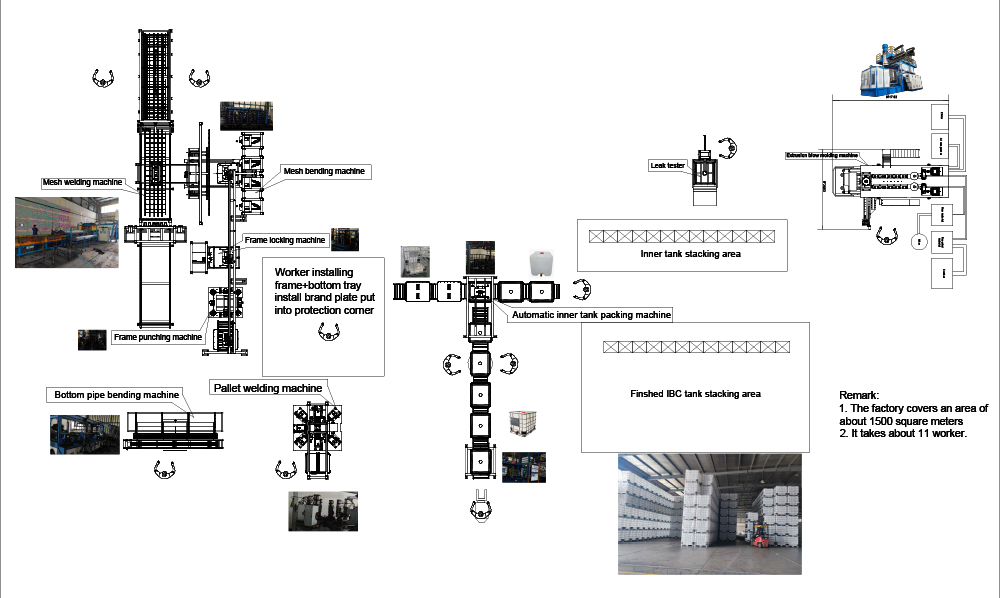

Whole solution for producing IBC tank