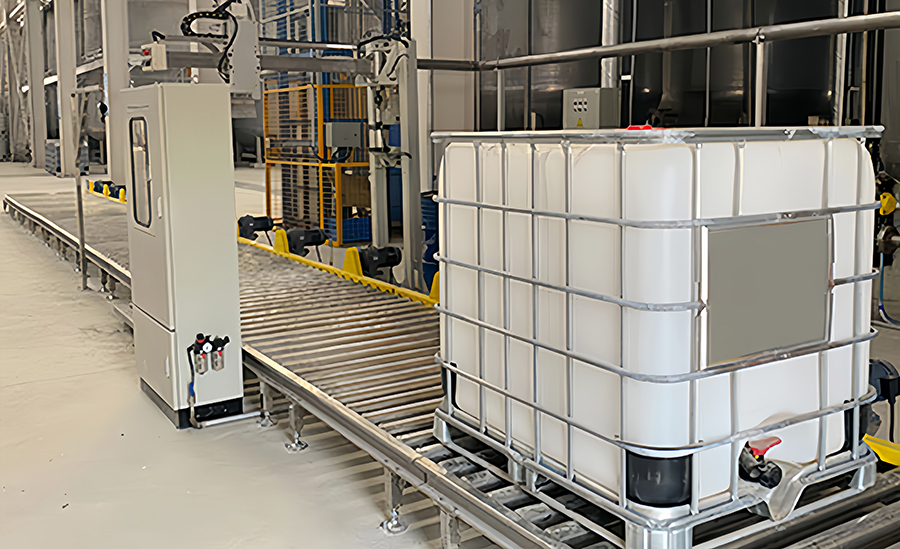

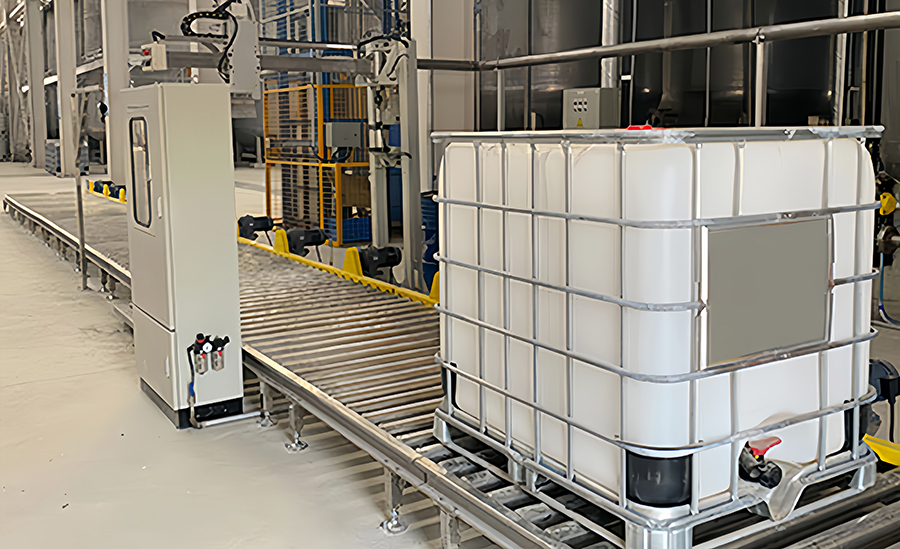

IBC tank filling machine is an efficient and accurate liquid filling equipment, which is widely used in chemical, food, pharmaceutical and other industries. It greatly improves production efficiency, reduces labor intensity, and brings huge economic benefits to the development of enterprises.

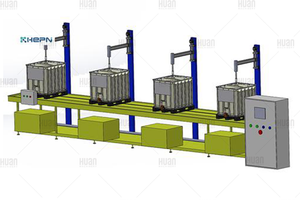

1000L-IBC tank filling machine parameters

Filling capacity: IBC ton barrel 1000L;

Power supply: AC220V 50/60HZ 0.2KW

Air source used: 0.5~0.7 Mpa

Filling capacity: 30~60 barrels/Hr

Filling accuracy: ≤0.05% FS

Graduation value: 0.1kg

Filling material: SUS304/SUS316/PTFE (optional)

Explosion-proof level: Exd11BT4

Features of 1000L-IBC tank filling machine

The system uses programmable PLC controller with reliable performance;

The filling is made using an overall process, with zero dripping and anti-splashing;

Quick release connector, easy to disassemble and clean;

The system target value can be set freely and the filling height is adjustable, suitable for rapid filling of packaging barrels of various specifications;

Equipped with large and small ball valve groups and double-stage filling, four-stage filling design of large, medium, small and trace quantities, making filling more accurate;

Filling is prohibited without a bucket on the weighing platform, and differential pressure zero-time bucket collision protection is provided;

Net weight/gross weight (automatic tare for each barrel) two filling methods are automatically selected;

One-click operation, easy to use; multiple windows display filling volume, number of barrels, cumulative volume and other information;

There is a signal indicator light for real-time display, and automatic alarm for deviations.

It has good stability, reduces losses, saves costs, improves operating efficiency and reduces manual operation pressure.

1000L-IBC tank filling machine application

Scope of application of additive filling machine: Mainly used in resin, emulsion, chemical, food, agriculture and other industries related to liquid materials