Principles and methods of blow mold temperature control

Mold temperature has a greater impact on the molding quality and molding efficiency of blow molded products. In a mold with a higher temperature, the molten rubber has better fluidity, which is beneficial for the rubber to adhere to the cavity and obtain a high-quality rubber surface, but it will make the rubber curing time longer and easy to deform when ejected. , For crystalline rubber, it is more conducive to the crystallization process, avoiding changes in the size of the rubber parts during storage and use; in a mold with a lower temperature, the molten rubber is difficult to adhere to the cavity, resulting in increased internal stress and surface Matte, causing defects such as silver streaks and weld marks.

Different rubber materials have different processing techniques, and the surface requirements and structures of various rubber parts are different. In order to produce rubber parts that meet the quality requirements in the most effective time, this requires the mold to maintain a certain temperature and mold temperature. The more stable, the more consistent the requirements on the size, shape, appearance and quality of the produced rubber parts will be. Therefore, in addition to mold manufacturing factors, mold temperature is an important factor in controlling the quality of rubber parts, and mold design should fully consider the control method of mold temperature.

The principle of mold temperature control

In order to ensure that the plastic parts with high appearance quality requirements, stable dimensions and small deformation are produced in the most effective time, the basic principles of mold temperature control should be clearly understood when designing.

(1) Different rubber materials require different mold temperatures.

(2) Molds with different surface qualities and different structures require different mold temperatures, which requires pertinence in the design of the temperature control system.

(3) When the actual mold temperature cannot reach the required mold temperature, the mold should be heated. Therefore, when designing the mold, full consideration should be given to whether the heat brought by the rubber material into the mold can meet the mold temperature requirements.

(4) Except for the heat that is brought into the mold by the rubber material, it is consumed by means of heat radiation and heat conduction, and most of the heat needs to be taken out of the mold by the circulating heat transfer medium. The heat in easy heat transfer parts such as beryllium copper is no exception.

(5) The mold temperature should be balanced, and there should be no local overheating or overcooling.

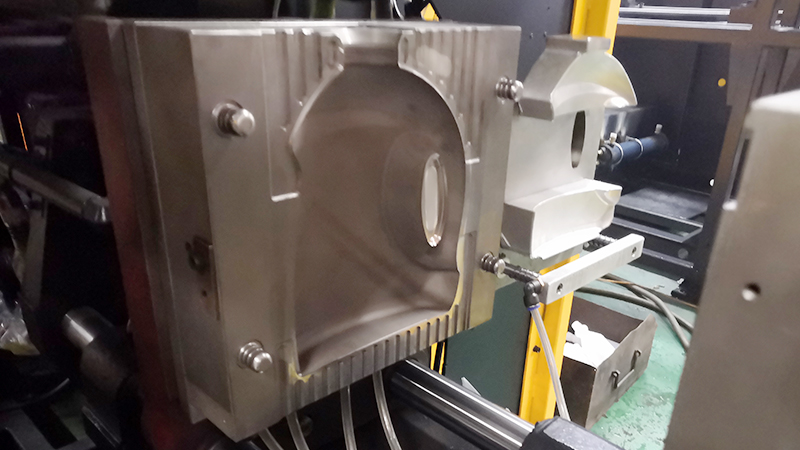

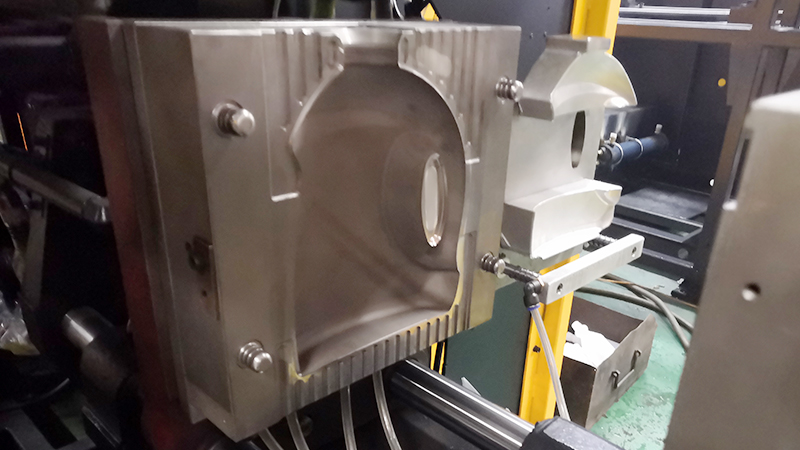

Mold temperature control method

The mold temperature is generally controlled by adjusting the temperature of the heat transfer medium and adding heat insulation boards and heating rods. The heat transfer medium generally uses water, oil, etc., and its channel is often called a cooling water channel.

Lower mold temperature is generally achieved by passing "mechanical water" (about 20 degrees) to the front mold and "frozen water" (about 4 degrees) to the rear mold. When the passage of the heat transfer medium, that is, the cooling water passage, cannot pass through certain parts, materials with higher heat transfer efficiency (such as beryllium copper, etc.) should be used to transfer heat to the heat transfer medium, or "heat pipes" should be used for local cooling.

Raising the mold temperature is generally achieved by passing hot water and hot oil into the cooling water channel (heated by a hot water machine). When the mold temperature is high, in order to prevent heat loss due to heat conduction, a heat insulation board should be added to the mold panel.

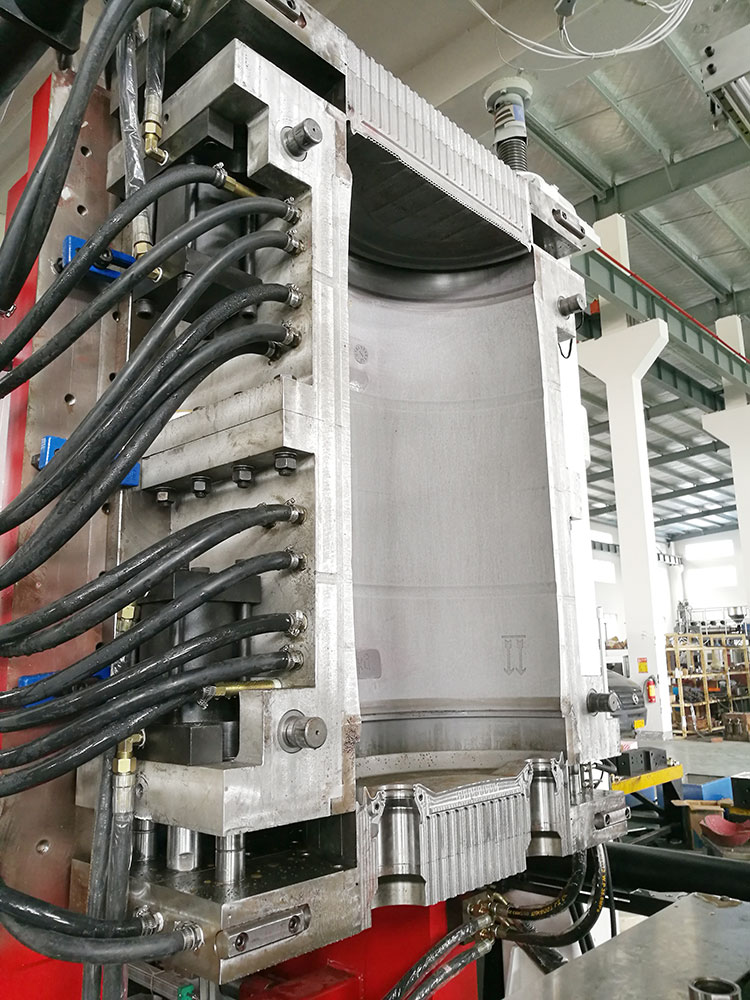

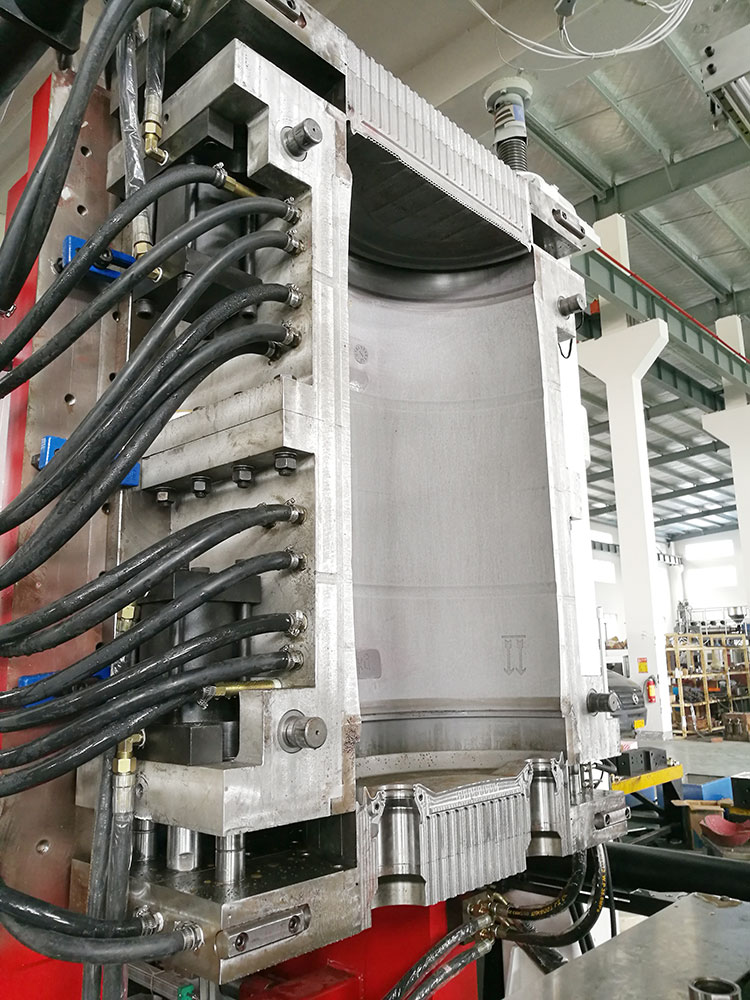

Cooling system design principles

The distance from the hole wall of the cooling water channel to the surface of the cavity should be as equal as possible, generally 15~25mm

The number of cooling water channels should be as large as possible, and it should be easy to process. The distance between two parallel water channels is 40~60mm

All molded parts are required to pass through a cooling water channel, unless there is no location, the part where the heat gathers is enhanced cooling

(1) Reduce the temperature difference between the water inlet and the water outlet. The temperature difference between the inlet and outlet water will affect the uniformity of the mold cooling, so the direction of the inlet and outlet should be marked during the design. The mold must be marked on the mold blank when the mold is made. The water transportation process should not be too long to prevent excessive temperature difference between in and out of the water.

(2) Minimize the existence of "dead water" (medium that does not participate in the flow) in the cooling water channel.

(3) The cooling water channel should be avoided at the foreseeable welding marks of the plastic parts.

(4) Ensure that the minimum side distance of the cooling water channel (ie the minimum steel thickness around the water hole) requires that when the length of the water channel is less than 150mm, the side spacing is greater than 3mm; when the length of the water channel is greater than 150mm, the side spacing is greater than 5mm.

(5) The cooling water channel should be sealed by "O" type glue when connecting, and the sealing should be reliable and without water leakage

(6) Other cooling methods, such as beryllium copper, heat pipes, etc., should be adopted for parts with difficulties in the arrangement of cooling water channels

(7) Reasonably determine the location of the cooling water joint to avoid affecting the installation and fixation of the mold.