Main technical parameters

Model | GGM1-4*250-1000-CD |

Rated Power | 4*250KVA |

Input Power | 630KVA |

Welding width | 1050 |

Maximum Welding Capacity | load bar | twisted rod |

8mm | 8mm |

Load Bar Height | 20-70mm |

Max. Load Bar Length | 8m |

Twisted rod length | 600-1000mm |

min. load bar pitch | >20mm |

first twsitd rod interval | >30mm |

welding method | double rods |

input voltage | 380V |

frequency | 50Hz |

duty cycle | 20% |

power for hydraulic station | 37KVA+5.5KVA |

max. pressure | 22MPa |

max. flow | 100+18L/min |

air pressure | 0.6-0.8MPa |

coolant flow | 8+4m3/h |

coolant temperature | 5-30degree |

coolant pressure | 0.2-0.3MPa |

cable size | 300m3 |

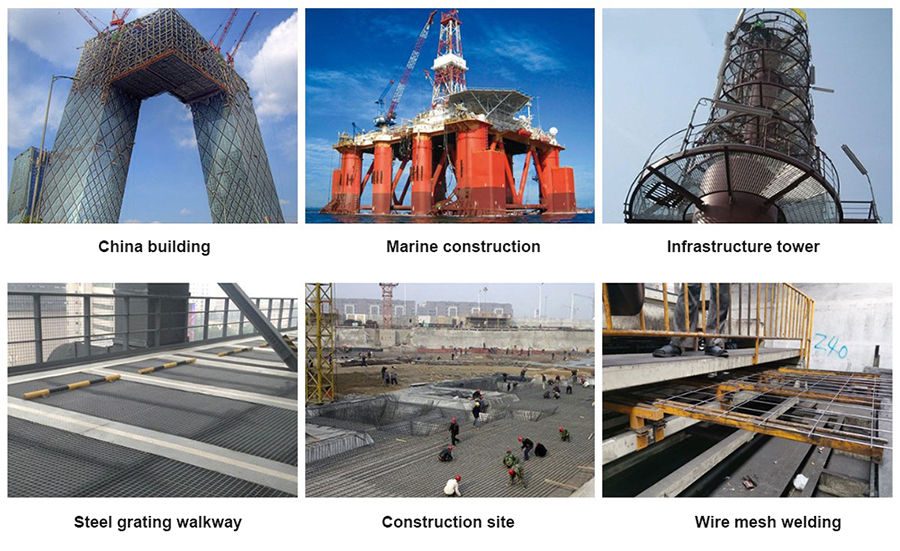

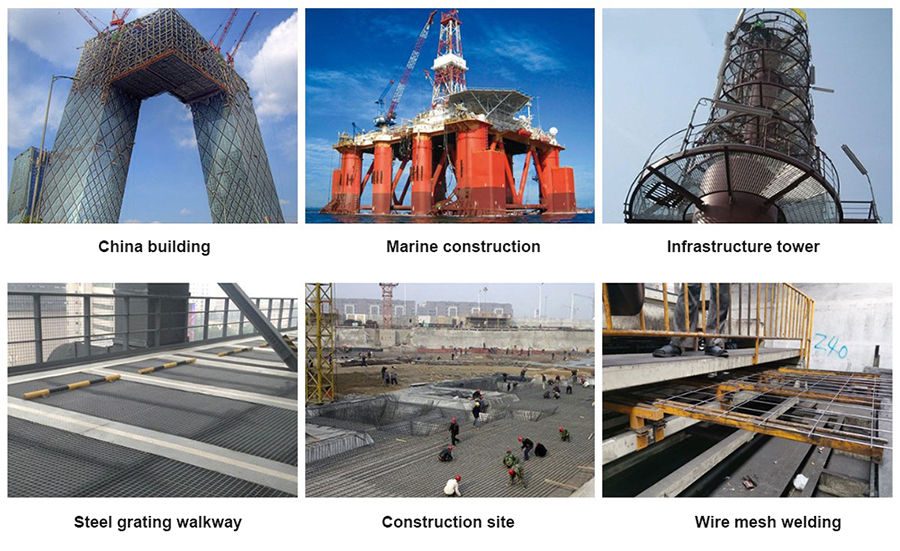

Application

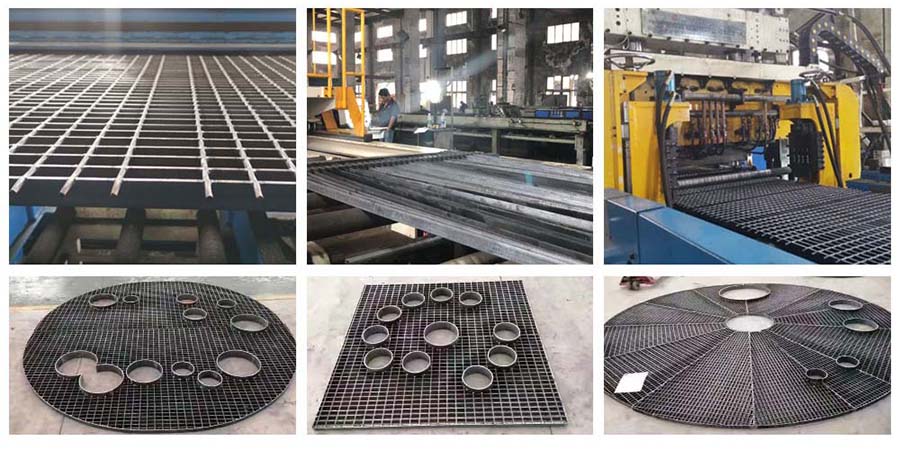

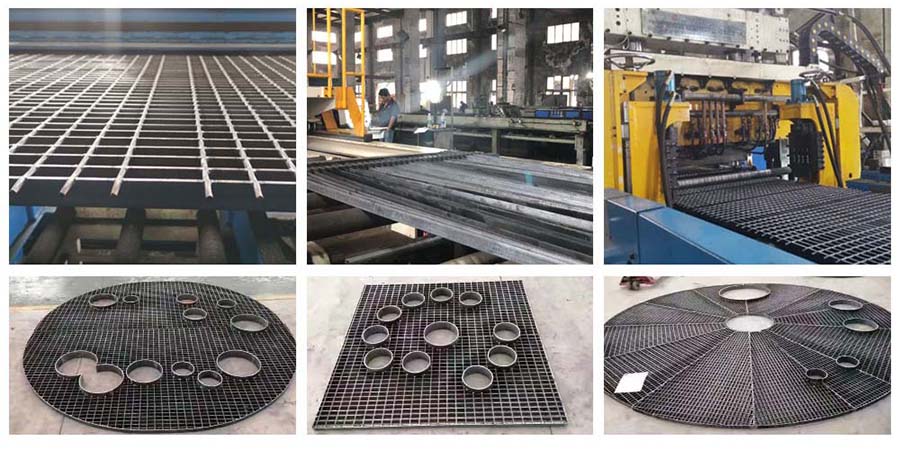

-Industrial Flooring: Engineered for precision, this advanced system ensures seamless fabrication of high-quality steel gratings

- Walkways and Platforms: Ensure safe and stable walking surfaces in diverse settings.

- Stair Treads: Create durable and slip-resistant stair treads for enhanced safety.

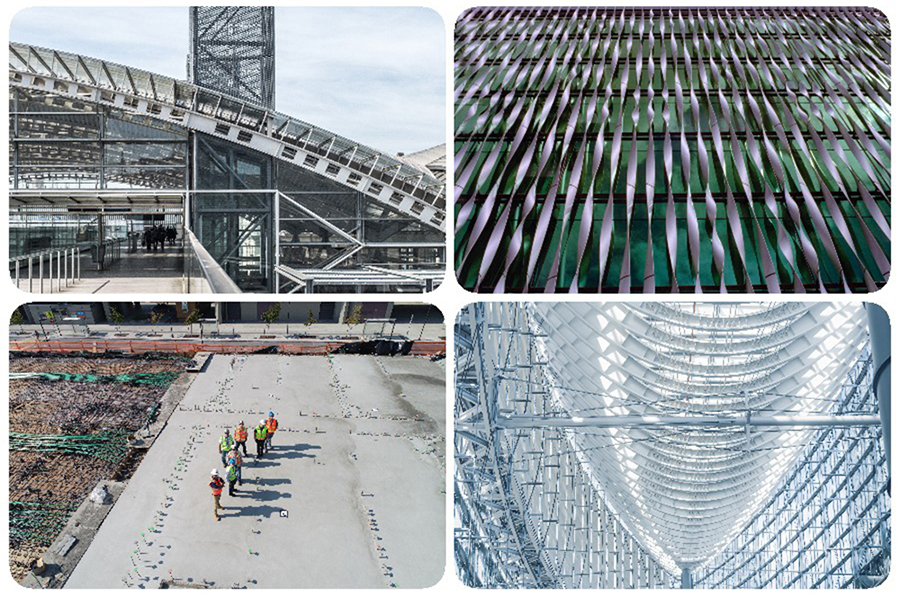

- Catwalks and Mezzanines: Support elevated pathways and additional storage space.

- Drainage Covers: Facilitate efficient water drainage with custom-designed grating.

- Security Fencing: Enhance perimeter security with sturdy and reliable fencing solutions.

- Trench Covers: Safeguard open trenches while allowing ventilation and access.

- Petrochemical Industry: Meet stringent requirements for corrosive and challenging environments.

- Renewable Energy Platforms: Provide stable foundations for platforms in renewable energy installations.

- Construction Sites: Support heavy loads and provide secure footing on construction sites.

These applications showcase the versatility and strength of your steel grating, addressing various needs across different industries. Let's take your projects to new heights!