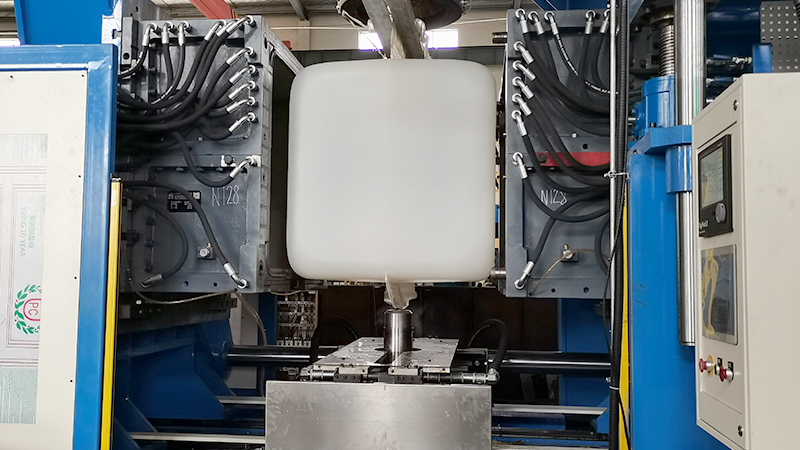

In the fast-paced world of IBC tank production, ensuring top-notch quality is the key to meeting customer demands and establishing a reputable brand. At HUAN MACHINERY, we understand the critical importance of delivering exceptional IBC Tank Blow Molding Machines that not only meet but exceed our customers' expectations. Let us take you on a journey through the customer-centric advantages of our machines, designed to revolutionize your IBC tank manufacturing process.

1. Solid and Sturdy Construction:

Our IBC Tank Blow Molding Machines are built to last. With a weight starting at 55 tons, they boast a robust and stable construction, ensuring durability and reliability throughout their lifespan. These machines are designed to withstand the rigors of demanding production environments, providing peace of mind to our customers.

At the core of our machine lies unwavering stability, ensuring smooth and reliable operations. The machine's robust design ensures steady performance, enhancing production consistency and minimizing disruptions.

2. Rapid Color Change Capability:

Time is precious in the manufacturing world, and we understand the value of efficiency. Our machines boast a rapid color change capability, allowing color transitions in just three hours. This seamless process reduces downtime and maximizes productivity, enabling our customers to meet tight production schedules with ease.

3. High Efficiency and Short Cycle Time:

We believe in delivering results promptly. Our IBC Tank Blow Molding Machines operate with high efficiency, boasting a production cycle time of only 160 seconds. This impressive speed ensures our customers can meet their production targets efficiently and stay ahead of the competition.

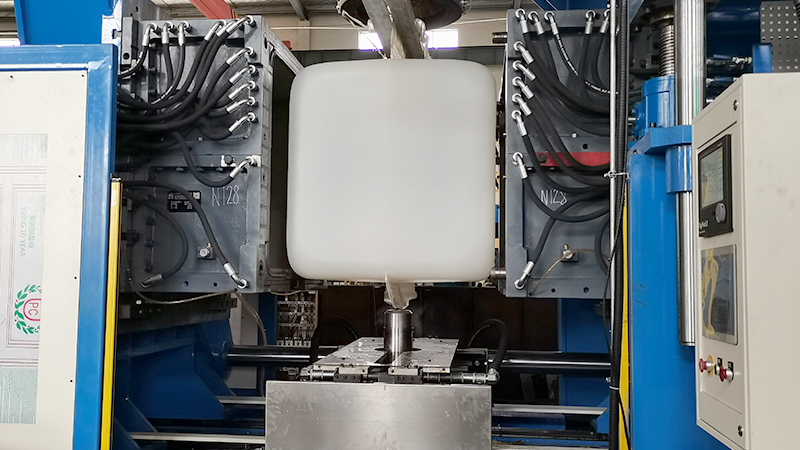

4. Lightweight and Uniform Product:

The quality of the final product matters, and we leave no room for compromise. Our IBC tanks are engineered to be lightweight yet robust, with an average wall thickness of 1.98 millimeters and a minimum of 1.6 millimeters. The uniform wall thickness ensures consistent product performance and reliability.

5. Uniform Multi-Layer Distribution:

IBC tanks often require multi-layer structures to meet specific demands. Our machines are equipped to achieve a uniform distribution of layers, with the thinnest outer layer, such as the electrostatic layer, reaching as low as 8% of the total wall thickness. This uniformity ensures the highest product quality and functionality.

6. High Extrusion Plasticization:

The success of blow molding heavily relies on effective plasticization. Our machines excel in high extrusion plasticization, ensuring exceptional molding results. With optimal plasticization, the final product boasts superior strength, durability, and dimensional accuracy.

7. Modular Design for Easy Assembly:

We understand the value of time for our customers. Our IBC Tank Blow Molding Machines feature a modular design, making assembly a breeze. Upon delivery, our machines can be efficiently assembled and put into production within a single day, ensuring minimal disruption to our customers' operations.

8. Energy-Efficient Performance:

Our IBC Tank Blow Molding Machine is engineered for efficiency, saving up to 500 kWh of electricity within 24 hours. With its smart design and optimized power consumption, it not only reduces costs but also contributes to sustainable manufacturing practices.

9. Versatile Screw Plasticization:

Our machine's screw plasticization is remarkably adaptable, making it highly versatile for different materials. It handles various types of plastics with ease, ensuring consistent and high-quality production across the board.

10. Convenient Mold Handling:

Efficiency extends beyond production. Our IBC Tank Blow Molding Machine is designed with convenient mold handling, streamlining mold changes and reducing downtime. This feature guarantees seamless transitions for uninterrupted production.

11. Swift and Responsive Service:

Our commitment to customer satisfaction knows no bounds. With our swift and responsive service team, we ensure any technical issues are addressed promptly, enabling our customers to resume production without delay.

12. Proven Success Across the Chinese Market:

We take pride in our extensive clientele in Jiangsu, Shanghai, Zhejiang, and Anhui. With numerous success stories and satisfied customers in these regions, our machine stands as a testament to its superior quality and performance.

At HUAN MACHINERY, our IBC TANK BLOW MOLDING MACHINE is the epitome of efficiency, reliability, and innovation. From rapid color changes to uniform product distribution, we prioritize customer needs to deliver the best results. Join us today and experience the power of cutting-edge technology and exceptional service in IBC tank blow molding. Let us be your trusted partner on the journey to success in the competitive market.