In order to make the IBC blow molding machine have better performance and continue to operate stably, HUAN Machinery engineers use their years of technical experience to continuously update the IBC machine. Ine's technology, so far 101 IBC blowing machines are running at home and abroad.

The Significance of Quality Control in IBC Tank Blow Molding:

For IBC tank manufacturers, quality control is the cornerstone of success. Ensuring every tank produced meets strict standards guarantees customer satisfaction and enhances brand reputation. Flawless performance in blow molding not only delivers products that perform as intended but also reduces the risk of costly defects and recalls. At HUAN MACHINERY, we recognize that our customers' success hinges on their ability to consistently deliver top-quality IBC tanks, and that is why we prioritize quality control at every stage of the process.

Advanced Technology for Quality Assurance:

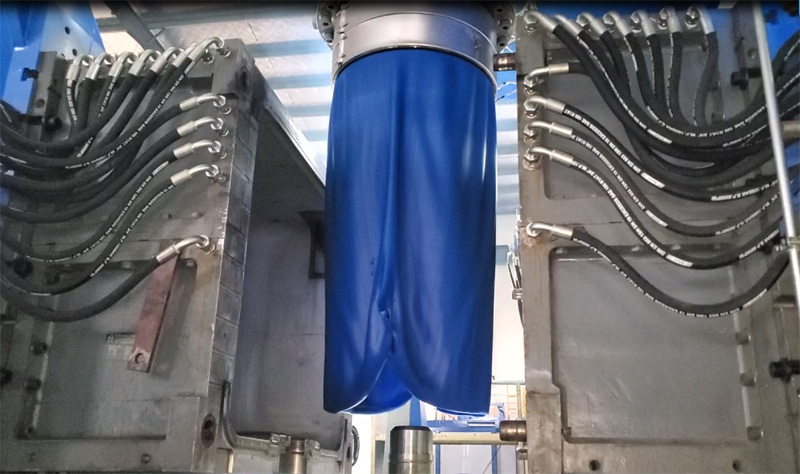

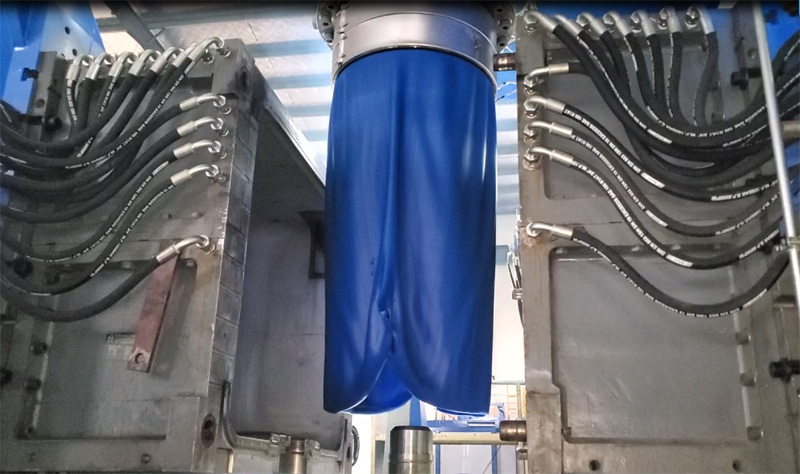

To maintain the highest standards of quality, we equip our IBC tank blow molding machines with cutting-edge technology. Our machines feature automated controls, enabling precise monitoring and adjustment of process parameters in real-time. The use of advanced sensors and data analytics ensures consistent material distribution and optimal cooling, resulting in uniform wall thickness and minimized defects. With our state-of-the-art technology, our customers can rest assured that their production process will be seamless and efficient, producing flawless IBC tanks with every run.

Ensuring Consistency in Material Selection:

As a customer looking to invest in an IBC tank blow molding machine, you want to ensure that the materials used in the production process are of the highest quality and consistency. At [Your Company Name], we understand the critical importance of material selection in achieving top-notch IBC tank production.

When you choose our IBC tank blow molding machine, rest assured that we prioritize your specific needs and preferences. Before shipping the machine to your facility, we conduct thorough trial runs using your existing materials. This ensures that the machine seamlessly integrates with your current production processes and delivers outstanding results.

If you are new to the IBC tank production line and unsure about material selection, we've got you covered. Our team of experts is well-versed in the properties of various materials, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and other specialized options. We take the time to understand your production goals and recommend the most suitable PE materials that align with your requirements.

By collaborating closely with you, we gain valuable insights into your unique production challenges and aspirations. Our goal is to provide tailored solutions that guarantee consistency and quality in every IBC tank produced. With our guidance in material selection, you can be confident in delivering IBC tanks that meet the highest industry standards and exceed your customers' expectations.

We take pride in being your reliable partner in IBC tank production. Our commitment to excellence means that we continuously stay updated with the latest material technologies and advancements. We are here to support you throughout the entire production journey, ensuring that your IBC tanks stand out in the market, offering unmatched performance and reliability.

By choosing our IBC tank blow molding machine, you gain access to not only cutting-edge machinery but also valuable expertise that empowers your business to thrive. Together, we can achieve consistency in material selection, elevating your IBC tank production to new heights and establishing a competitive edge in the industry. Your success is our success, and we are here to help you every step of the way.

Optimizing Process Parameters:

The heart of flawless performance in IBC tank blow molding lies in optimizing process parameters. Our team of experts works closely with customers to fine-tune every aspect of the process, from temperature and pressure to cooling rates and cycle times. By employing advanced simulation and modeling techniques, we can predict potential issues and optimize the process for optimal results. The result is a production line that consistently delivers IBC tanks with superior strength, dimensional accuracy, and surface finish.

We understand that each IBC tank production requires tailored solutions. Our cutting-edge IBC tank blow molding machine offers 1, 2, and 3 layer options, ensuring a perfect fit for your specific needs. From wall thickness to material composition, customize every parameter effortlessly with our machine. Elevate your IBC tank production with precision and efficiency, backed by our expert guidance and support. Partner with us and unlock the power of customization today.

Inspection and Testing Protocols:

We leave no room for compromise when it comes to quality assurance. Every IBC tank undergoes rigorous inspection and testing at multiple stages of the production process. We conduct thorough dimensional checks, leak tests, and material property evaluations to ensure each tank meets our stringent quality standards.

In addition to these critical tests, we implement an IBC tank thickness test to ensure the uniformity of the barrel wall. Our advanced equipment allows us to precisely measure the thickness of each IBC tank, ensuring that the wall thickness falls within the optimal range of 1.5mm to 1.8mm. This meticulous testing process eliminates any variations in wall thickness, providing you with IBC tanks of exceptional quality and reliability.

Our commitment to quality control empowers our customers to confidently deliver IBC tanks that exceed expectations. With our unwavering dedication to precision and performance, you can rely on our IBC tanks to safely and efficiently transport your valuable liquids and materials.

Choose HUAN MACHINERY for top-of-the-line IBC tanks that meet the highest industry standards and provide a dependable solution for your storage and transportation needs. Experience the confidence that comes with consistent wall thickness and exceptional product integrity.

Operator Training and Expertise:

At HUAN MACHINERY, we understand the pivotal role skilled operators play in ensuring the flawless performance of our IBC tank blow molding machines. Before shipment, each machine undergoes rigorous testing to validate its functionality. We meticulously record these tests through videos and images, providing tangible evidence of the machine's impeccable condition prior to delivery.

Upon the arrival of our IBC tank production line at the customer's facility, our team of experienced technicians will be dispatched for on-site installation and guidance. We leave no room for uncertainties, ensuring a smooth setup process for our customers. After successful installation and commissioning, our technicians will conduct a comprehensive acceptance test, ensuring the machine meets all specifications and requirements.

To empower our customers' operators and ensure they are well-versed in maximizing the machine's potential, we offer a one-month training program at the customer's factory. Our dedicated technician will patiently guide and train the operators, providing invaluable insights into the machine's operation and maintenance. This hands-on training equips the operators with the necessary expertise to handle the machine with confidence.

Our commitment to customer satisfaction extends beyond the initial training period. We offer continuous online support and training, always standing by to address any concerns or queries that may arise. Our team is just a message or call away, providing real-time assistance to ensure uninterrupted production and operational efficiency.

We view our customers' success as our own. By investing in operator training and expertise, we empower our clients to optimize their production processes, reduce downtime, and elevate their IBC tank production to new heights of quality and efficiency. With our unwavering support and technical expertise, our customers can rest assured that they are in the hands of industry experts who are committed to their continued success.

Our Commitment to Quality:

We take pride in being more than just a supplier; we are your partners in success. We are committed to delivering exceptional products and services that exceed your expectations. Our passion for quality control drives us to continuously improve and innovate, ensuring that our customers can rely on us for top-of-the-line IBC tank blow molding machines and outstanding customer support.

In the competitive world of IBC tank production, flawless performance is the key to success. We understand the demands of the industry and are dedicated to providing cutting-edge technology, meticulous quality control, and unwavering customer support. When you choose our IBC tank blow molding machines, you choose excellence and peace of mind. Let us be your partner in delivering the highest quality IBC tanks to the world.