In the realm of modern manufacturing, efficiency stands as a cornerstone for success. As industries evolve and competition intensifies, the significance of optimizing production processes has never been more vital. This article delves into the pivotal role of IBC production lines, unraveling their key contributions to streamlined manufacturing and setting the stage for a comprehensive exploration of their capabilities.

In the intricate realm of manufacturing, efficiency stands as the cornerstone of success. It's the driving force that transforms raw materials into remarkable products, redefining industries and setting benchmarks. Amidst this dynamic landscape, the IBC (Intermediate Bulk Container) production line emerges as a pinnacle of efficiency, seamlessly orchestrating an array of processes to create a product that's both functional and reliable.

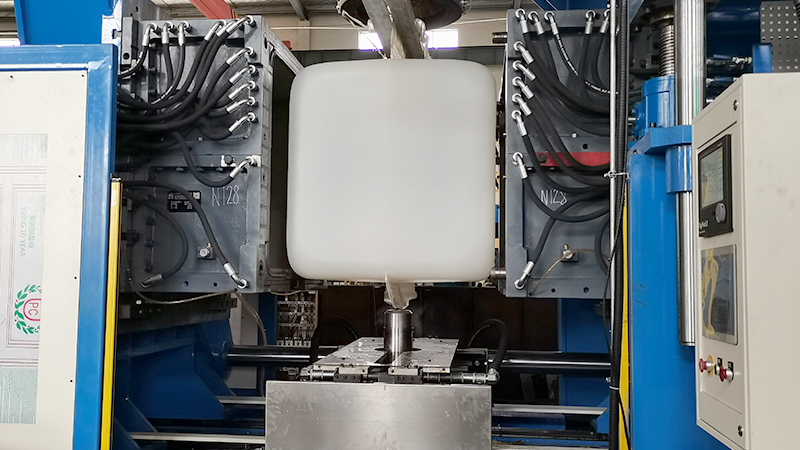

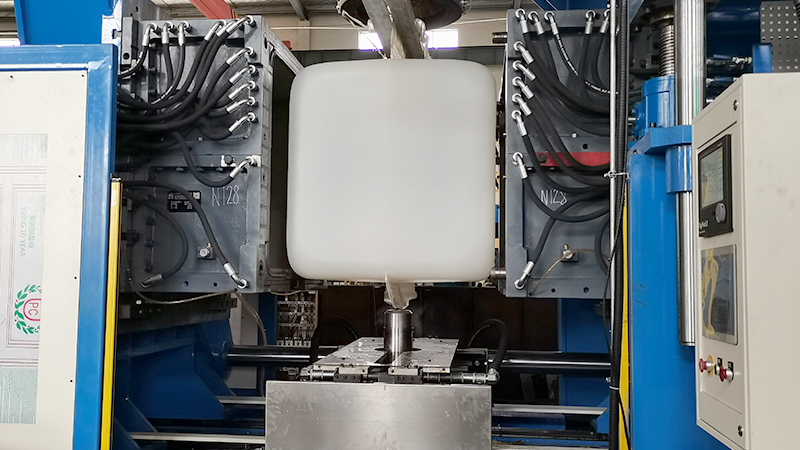

At its heart, the IBC production line is a symphony of craftsmanship and technology, where each instrument plays a crucial role. It's a composite ensemble, featuring the precision of metal stamping, the ingenuity of blow molding, the sturdiness of frame assembly, and the finesse of plastic injection molding. These core components converge not merely as machinery, but as artisans shaping the future of industrial packaging.

The journey along the IBC production line is a testament to its power. It's a journey of transformation, where sheets of metal are meticulously shaped into durable frames, where liquid plastic is artfully molded into sturdy tanks. The process is not just about manufacturing; it's about meticulous crafting, ensuring that each IBC tank that emerges is a product of excellence.

The IBC production line is a true marvel of coordination and synchronization. From the initial stamping of metal sheets to the final injection molding of plastic components, every step is a part of an intricate dance, a dance that yields a remarkable production capacity. With the ability to IBC tanks blow molding 500 pcs per dayand the whole IBC tanks producing 1440 pcs per hour, the line showcases a level of efficiency that's nothing short of extraordinary.

What sets the IBC production line apart is its orchestration of diverse processes, each seamlessly connecting with the next. From the initial metal stamping, which crafts the foundation, to the precise blow molding that shapes the vessel, to the strategic frame assembly that adds structural integrity, and finally, the meticulous plastic injection molding that gives rise to additional components – the harmony is palpable.

The synergy between these processes is not happenstance; it's a testament to design and engineering prowess. Every step is a part of a meticulously choreographed dance, where the movements are calibrated to achieve a singular goal: delivering IBC tanks of exceptional quality. The line doesn't merely produce; it refines, it elevates, and it ensures that every IBC tank that emerges is a testament to craftsmanship and precision.

In the grand tapestry of manufacturing, the IBC production line is a masterpiece. It transforms raw materials into functional art, and in doing so, it streamlines industries, enhances operations, and fosters reliability. The journey is one of transformation – from sheets of metal and pellets of plastic to fully-fledged IBC tanks, each embodying strength, durability, and efficiency.

In essence, the IBC production line isn't just a technological marvel; it's a promise. A promise of quality, of efficiency, and of solutions that meet and exceed the evolving needs of industries. It's a reminder that behind every IBC tank stands a meticulous process, an amalgamation of expertise, and a commitment to excellence. The power of the IBC production line isn't just in what it creates; it's in the impact it has on industries, businesses, and the seamless flow of operations.

In the fast-paced world of industrial manufacturing, the pursuit of efficiency often takes center stage. Yet, amidst the clamor for speed and output, a crucial factor should never be overshadowed – compliance with industry standards and regulations. It's the golden thread that weaves through the entire IBC (Intermediate Bulk Container) production line, upholding the pillars of quality, safety, and customer satisfaction.

The process begins with design, where the blueprint is more than a sketch – it's a roadmap to compliance. Each contour, dimension, and material choice is a brushstroke painted in accordance with industry-specific guidelines. Our IBC production line embodies not just the art of manufacturing, but the science of adherence.

As the production line hums with activity, compliance remains its guiding star. Every station, every station master – be it metal stamping, blow molding, frame assembly, or plastic component injection – adheres to a choreography choreographed by regulations. It's a dance of precision, where each step is scrutinized, each move aligned with industry rhythms.

Quality isn't left to chance; it's meticulously cultivated through rigorous inspection and testing. Compliance serves as the litmus test, with each IBC tank passing through the crucible of scrutiny. Dimensional checks, leak tests, material property evaluations – each examination is a testament to our commitment to not just meeting but exceeding industry standards.

In this intricate dance of compliance and quality, the IBC production line isn't just a conduit for creation; it's a tapestry of assurance. Each IBC tank is not just a vessel; it's a promise – a promise of unwavering adherence to standards, a promise of delivering products that inspire trust, and a promise of elevating brands through the harmonious symphony of compliance and quality. As you embark on your journey of IBC production, rest assured that our production line is more than machinery – it's a testament to the power of compliance in shaping a world of impeccable quality.

In the dynamic world of manufacturing, the IBC production line shines as an epitome of innovation and efficiency. It seamlessly integrates stages, ensures compliance, and fuels innovation.

From metal stamping to IBC blow molding, frame manufacturing to plastic component injection, each step is an interconnected piece in the IBC production line. This orchestrated harmony isn't just about workflow; it's about tapping into collective potential.

Meeting industry regulations isn't just a requirement; it's a testament to our commitment to quality. Every facet of the IBC production line aligns with rigorous standards, ensuring superior products that boost customer satisfaction.

The IBC production line is a hub of innovation. It's where creativity and practicality converge, resulting in optimized processes and exceptional products. With advanced blow molding technology, color consistency, and precise wall thickness, innovation propels us forward.

Choosing the IBC production line isn't just a business decision; it's a step towards your future success. It's the avenue to elevated efficiency, unmatched quality, and boundless potential. With each IBC tank produced, you're not just manufacturing; you're shaping your triumph.

In a competitive world, the IBC production line is your edge. It's more than a process; it's your key to enhancing your brand, surpassing expectations, and propelling towards a triumphant future.

Explore the IBC production line – where efficiency meets innovation, compliance instills confidence, and success is the only destination. Your journey begins now.