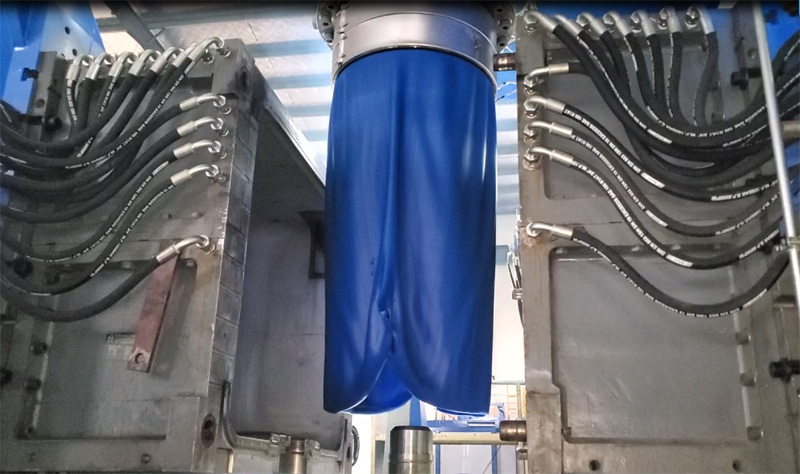

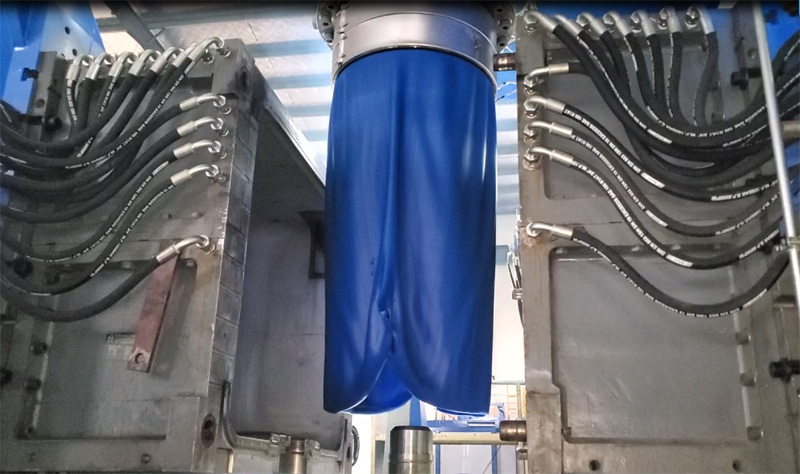

Hey there, dear friends! Today, we're going to delve into the exciting world of IBC tank blow molding and explore the brilliant solutions to conquer color variations. You know, achieving consistent and vibrant colors in your IBC tanks is not just about making them look stunning; it's a crucial aspect that impacts the overall quality of your products and how your brand is perceived in the market. So, let's dive right in and uncover the secrets to mastering color consistency in IBC tank blow molding!

Imagine this: you walk into a store, and there they are - rows of IBC tanks, each one a different shade of blue. Not exactly the striking display you had in mind, right? Color is more than just aesthetics; it's an essential element that influences customer perception and brand identity. Consistent and vibrant colors in your IBC tanks convey a sense of quality and professionalism, making your products stand out in the market. So, let's embark on this journey together and explore how we can overcome color variations and create IBC tanks that capture the hearts of your customers!

First thing, let's identify the culprits behind those pesky color discrepancies. It all starts with the raw materials. Using high-quality materials and masterbatch lays a strong foundation for color consistency. But, hey, we get it - incorporating recycled materials is a sustainable choice. However, it can introduce color variations due to differences in color values and uneven mixing. No worries, though! We've got a brilliant solution for you.

Brilliant Solutions for Material Control:

To tackle color variations caused by recycled materials, it's essential to adjust material proportions and mixing time. With our expertise, we can help you fine-tune these parameters to ensure material uniformity and minimize color discrepancies. Plus, we'll guide you in choosing the right materials and masterbatch to enhance color consistency in your IBC tanks. We've got your back, and we'll make sure your IBC tanks shine with brilliant colors!

Gone are the days of material restrictions! With our cutting-edge technology, our IBC tank blow molding machine boasts an unbiased screw design, enabling efficient plasticization of various materials. Whether you're using high-density polyethylene (HDPE), polypropylene (PP), or even specialty polymers, our machine ensures uniform and precise plasticization, guaranteeing consistent product quality across material types.

Quality and efficiency go hand in hand. At HUAN MACHINERY, we're committed to delivering the best, and that includes an exceptional yield rate of 99.9%. By optimizing the entire blow molding process, from material handling to cooling, we ensure minimal waste, maximum productivity, and unparalleled profitability. With us, you can bid farewell to costly product rejects and embrace a new era of consistent, high-yield IBC tank production.

Lightning-Fast Color Change: Seamlessly Switch from Blue (or Black) to White Time is money, and we understand the need for swift color changes to meet market demands. Our IBC tank blow molding machine is engineered for rapid color transitions, offering an impressive color changeover speed that sets a new industry standard. Switch from blue (or black) to white - or any other color - with ease and efficiency, thanks to our innovative design and streamlined color management system. Say hello to dynamic product diversification and reduced downtime!

Mastering Uniform Mixing Techniques:

Picture this: as your materials and colorants are blended, they create a perfect symphony of colors, ensuring uniformity and vibrancy in every IBC tank. But sometimes, electrostatic forces can cause colorants to separate from the material and stick to the hopper's walls, leading to color fluctuations during blow molding. No need to fret! Our brilliant solution involves replacing vacuum loaders with hot air dryers and utilizing manual feeding methods. This way, we prevent colorant separation and maintain color consistency throughout the production process.

Ensuring Temperature Control and Color Stability:

Temperature can be a bit of a tricky character when it comes to blow molding. Unexpected temperature changes can lead to color discrepancies, leaving you with less-than-ideal IBC tanks. Fear not! Regular inspection and maintenance of the heating system are crucial to avoid such mishaps. Our brilliant solution involves keeping a close eye on the heating coils and promptly repairing any damage or malfunctions. With our temperature control expertise, you can ensure stable and consistent colors in your IBC tanks.

Optimal Process Parameter Adjustment:

Now, let's talk about making those necessary process adjustments without compromising color consistency. You don't have to be an alchemist to get it right! With our guidance, you can confidently adjust blow molding temperature, back pressure, cycle time, and colorant dosage while observing their impact on color. It's like finding that perfect recipe to create the most brilliant colors in your IBC tanks!

Quality Assurance and Color Testing:

We believe that the key to success lies in meticulous quality control and color testing. By implementing robust protocols and using color measurement devices, we ensure that your IBC tanks meet the highest standards of color consistency. With regular color testing and calibration, you can maintain uniformity in your products, leaving your customers impressed and satisfied.

Real-Life Success Stories:

What's better than hearing real success stories from manufacturers just like you? We've witnessed our brilliant solutions transforming IBC tank production for companies across various industries. They've not only overcome color variations but also improved efficiency, reduced waste, and gained a competitive edge in the market. These inspiring stories show how mastering color consistency can lead to brighter prospects for your business!

Reinforcing the Significance of Color Consistency:

As we wrap up our colorful journey, we can't emphasize enough how essential color consistency is for your IBC tank blow molding success. By embracing our brilliant solutions, you can elevate your brand and leave a lasting impression on your customers. Achieving uniform and vibrant colors is not just a dream; it's within your reach with our expertise by your side.

With HUAN MACHINERY, you're not just getting a supplier; you're gaining a partner who is passionate about your success. Our team of experts is here to support you every step of the way, from material selection to process optimization. Together, we'll create IBC tanks that not only impress but also reflect the brilliance of your brand.

So, let's embark on this colorful adventure together! Contact us today, and let's start transforming your IBC tank blow molding into a masterpiece of color consistency. With [Your Company Name], you'll always have a brilliant solution at hand. Here's to a vibrant and successful future for your business!