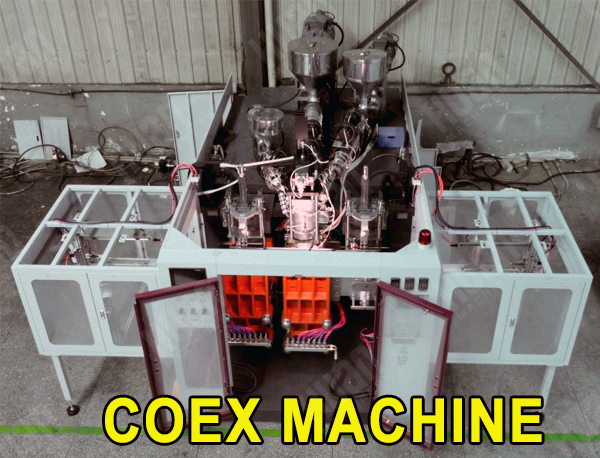

Application of multi-layer Coex technology in blow molding machine industry

hollow extrusion blow molding machine

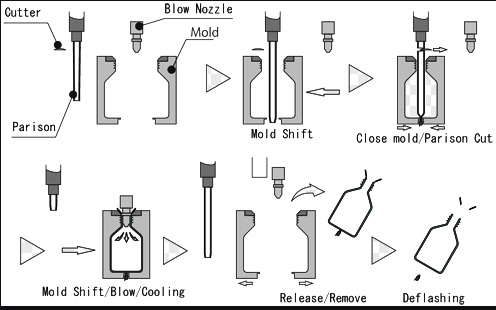

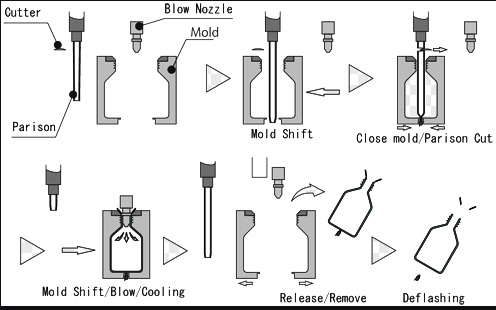

Hollow extrusion blow molding equipment is to feed raw plastic material such as HDPE (High density Polyethylen), PP (polypropylene), PVC( Polyvinyl chloride) etc. through extruder for melting preform into forming mold, then use the compressed air to deform the blank along the die cavity. It is cooled quickly and shaped from the die to blow the hollow bottles with short neck. Hollow extrusion blowing machine is a fast developing plastic molding method at present.

Application scope of hollow extrusion blow molding machines

Extrusion blow molding machine, originated in 1930, today already involved in various industries. Blow molding technology and equipment cost is relatively not high, and the advantage is that it can form complex hollow products, then what sort of fields our extrusion blow molding machines are applied?

Chemical industry package

-Industrial chemical bottles/jerry can/ drums etc.

-Lubrication oil jerry can 1L/2L/4L/5L

-engine oil jerry can 1L/2L/5L/30L/60L/220L

-220L chemical drum etc..

-flexible oil hose

Daily chemical bottle

洗发瓶 shampoo bottles

沐浴露瓶 bath bottle

护肤瓶 skin care bottle

强力去污瓶 decontamination bottle

洗涤精瓶/洗衣液瓶detergent bottle/can jerry can

洗厕液瓶 toilet liquid bottle

消毒液瓶 disinfectant bottle

消毒纸巾桶 sterilized tissue barrel

3. 农用化工桶&瓶 farming chemical bottle/jerry can

农药瓶/桶 Pesticide bottle/jerry can

4. 医药化工瓶 medical chemical bottle/jerry can

眼药水瓶(LDPE)eye drop bottle

废弃物瓶/桶 waste material bottle

二、食品包装 food package

1. 牛奶瓶 milk bottle

2. 果酱瓶 ketchup bottle/ juice bottle

3. 罐头瓶 preserved can bottle/can

4. 食用油桶 edible oil jerry can /bottle

Auto car part

Auto car oil tank

Auto car water tank

Spoiler

Auto car air intake hose

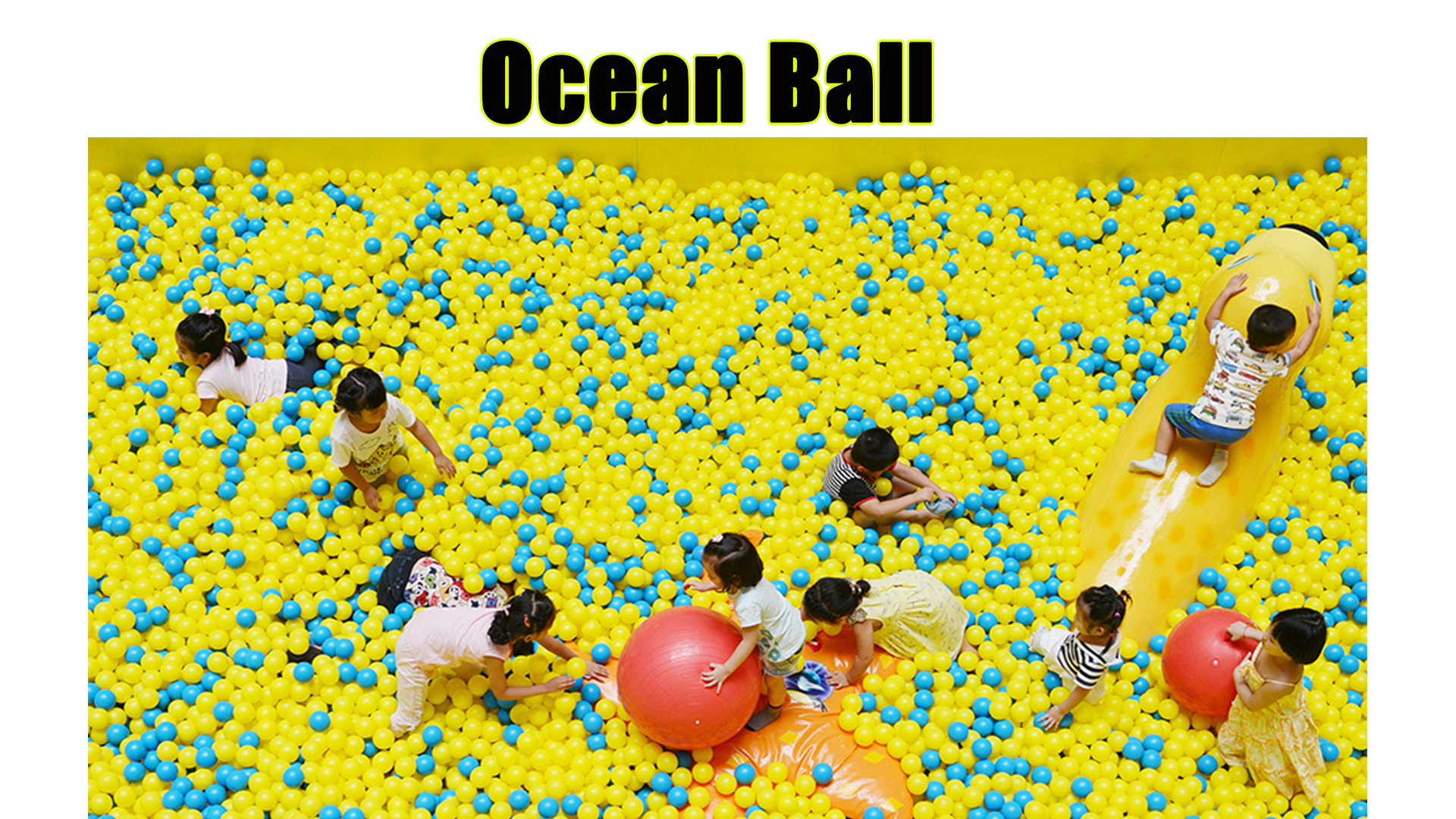

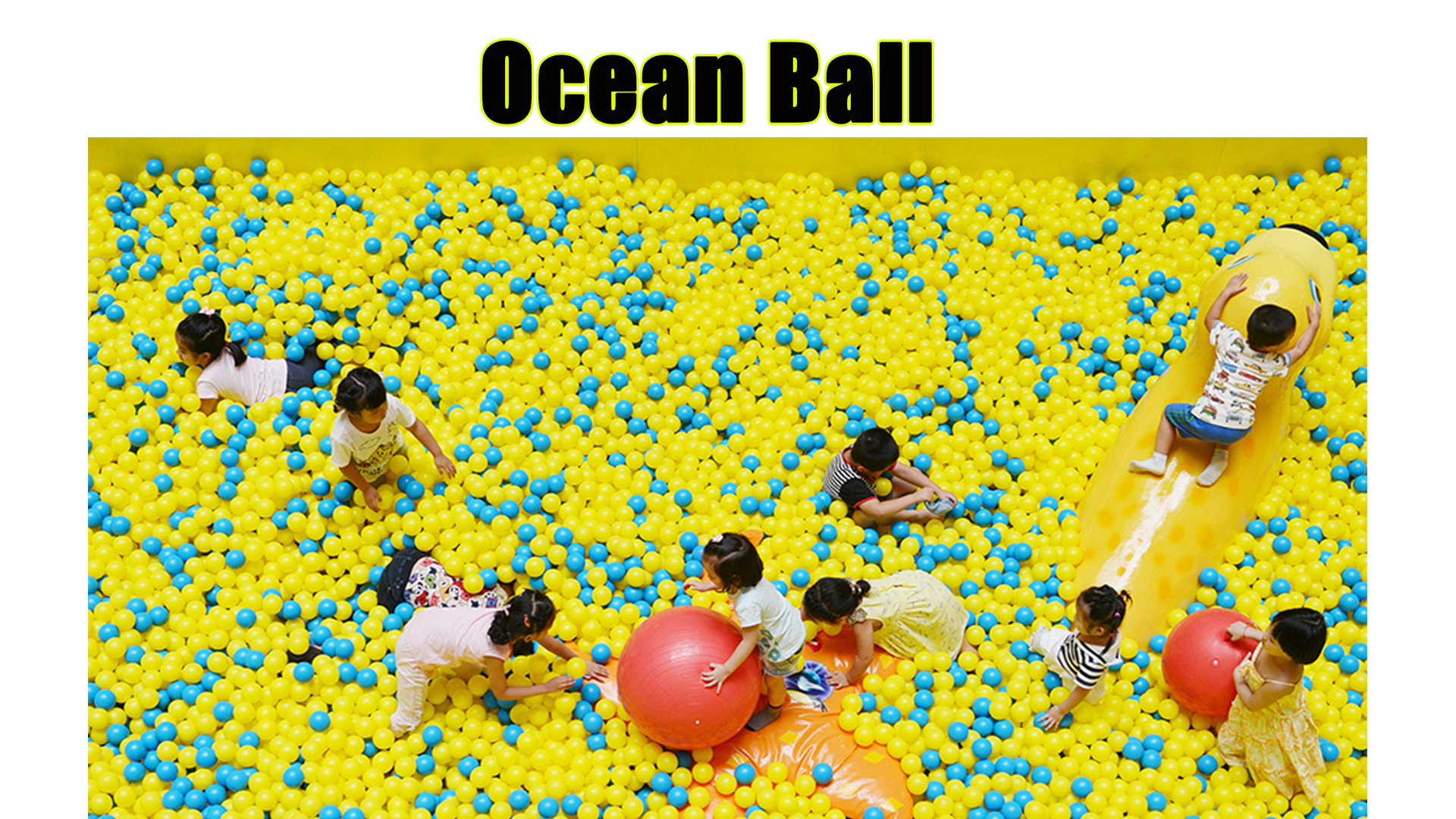

Children toy plastic products

Ocean sea ball

Horse

Slide

Moto cycle

basketball stand

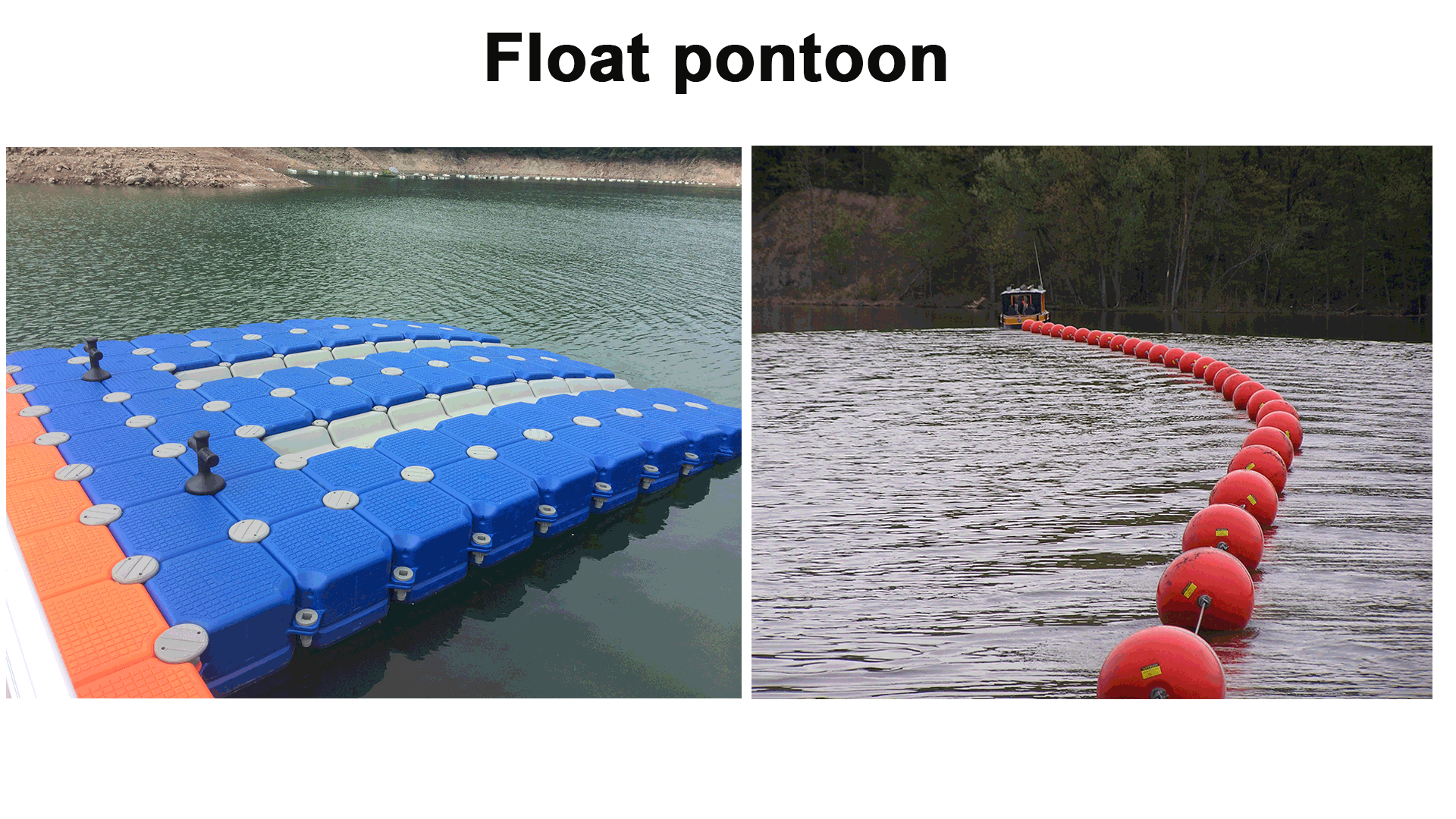

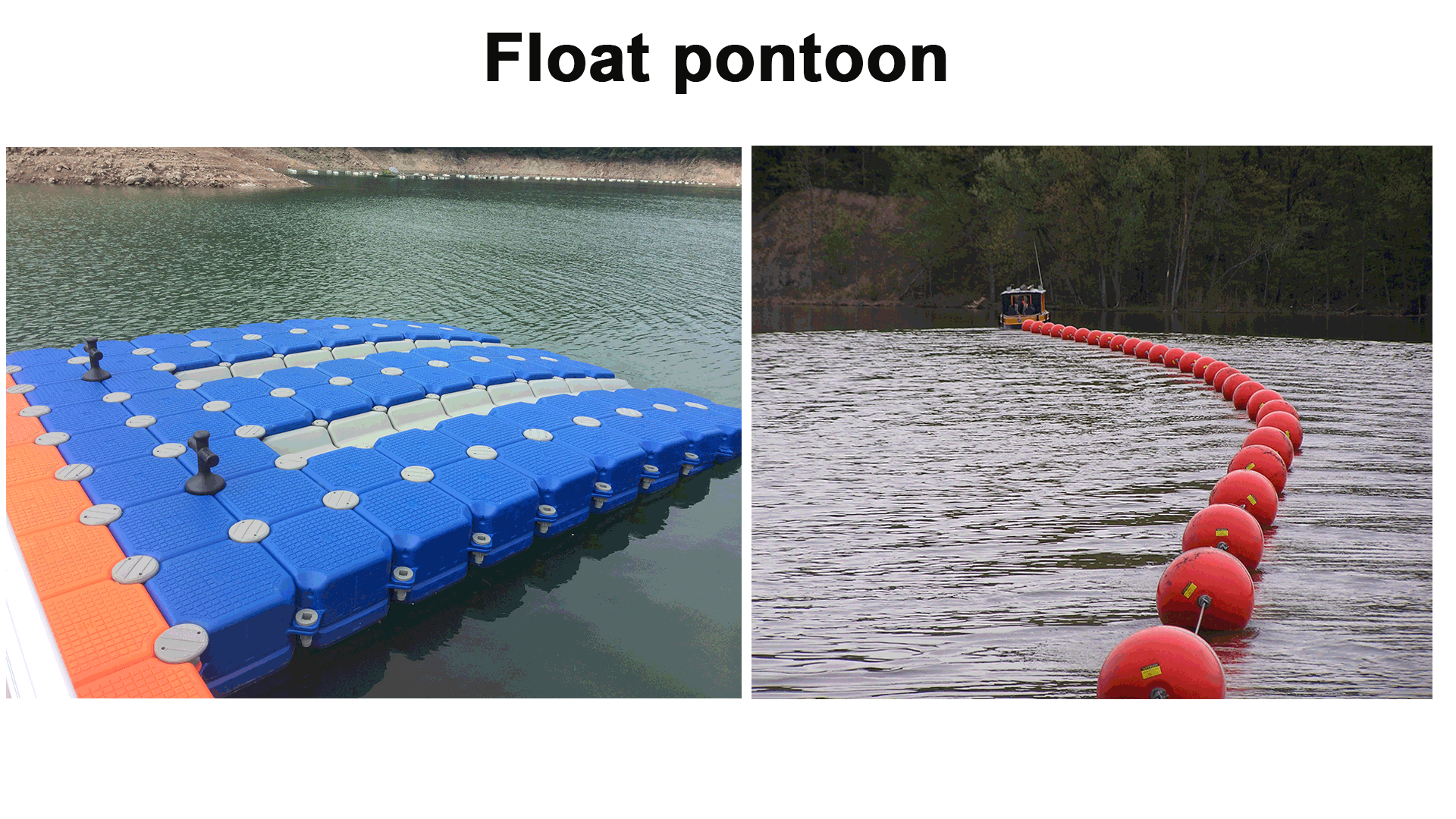

Folating sea products

pontoon block

pontoon

pontoon ball

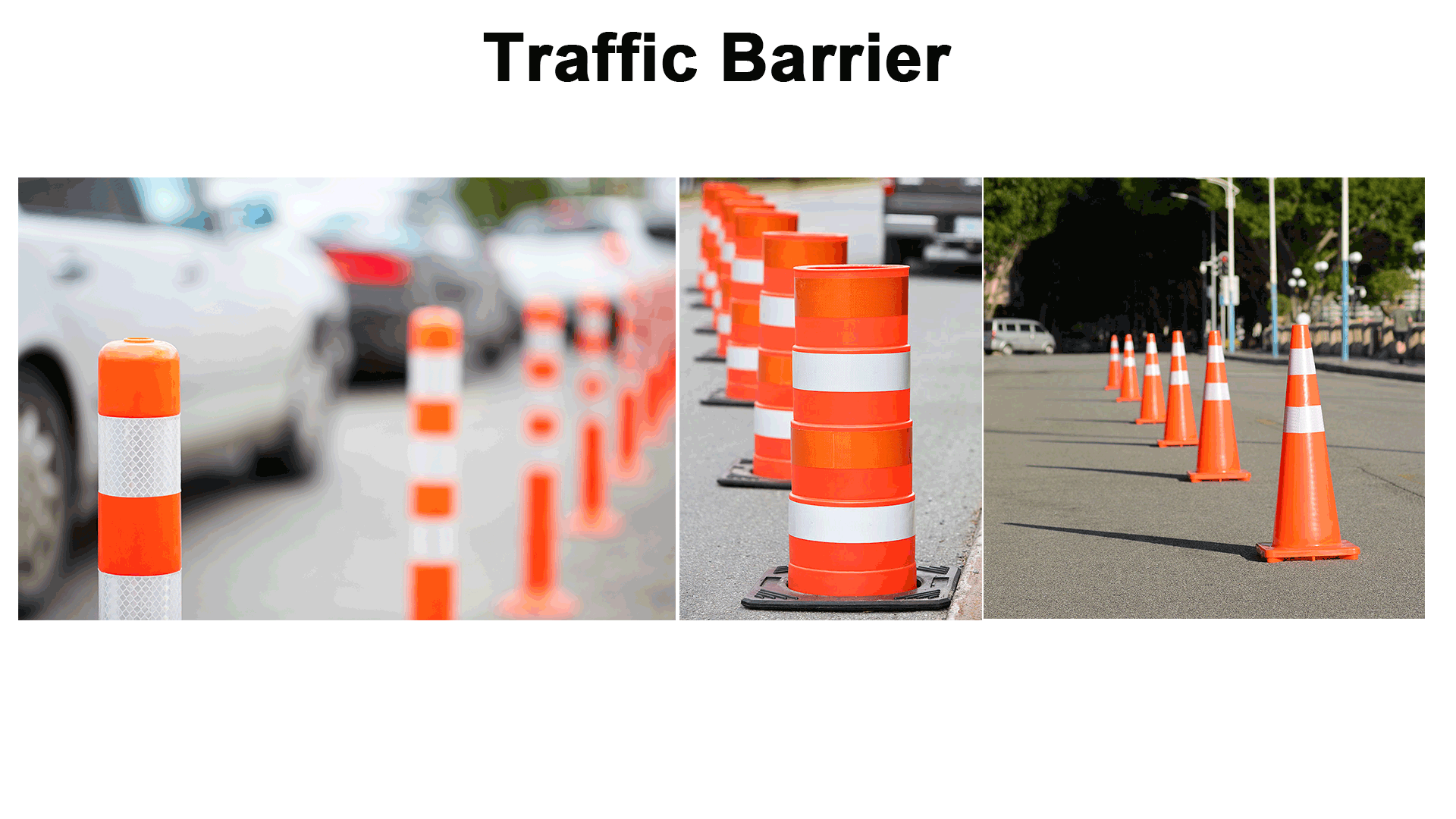

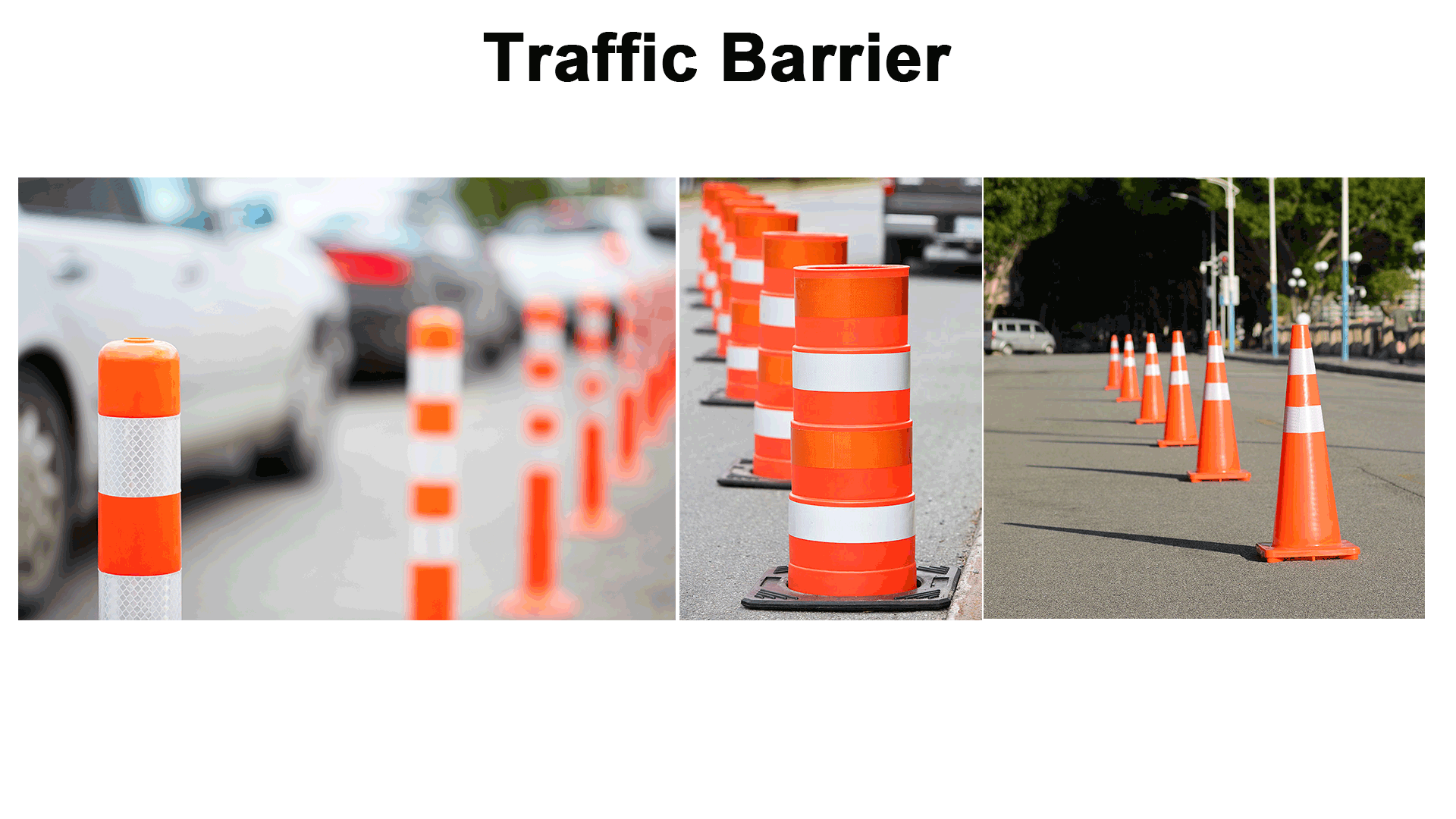

Traffic products

Fence

road block tube

road block

Water pot/ jerry can/ bottle

(LDPE)Soft water bag

Garden spray watering can

1handle type water tank

long neck single color/double color pot

water storage tank (big)

Seat

Safety seat

sports seat

Plastic pallets

table plate

pallet

Stretcher

Plastic model for shop

Adult size

Children size

half body size

Multi-layer coex blow molding machine application

Multi-layer coextrusion blow molding machine adopts different extrusion system to produce multi-layer plastic bottles. Normally 3 necessities:

1.Function necessities:

Decrease the oxygen permeability, such as food preserve can and juices bottles etc.

Improve the impermeability, such as pesticide bottles and jerry can;

Improve the beauty of the surface, such as daily chemical bottles, adding pearl powder on the out layer to form bling pearlescent feeling.

produce one transparent line on un-transparent bottle for observing the level of liquid inside.

2.Environmental demand

Once plastics are synthesized, no way to turn back! In the past 50 years, the global production of plastic has been increased by 20 times and caused 7 billion tons of plastic waste which is named “ white pollution”. At present, there are 120 million tons of disposable plastic products in the world yearly, of which only 10% are recycled and about 12% are burned, other more than 70% are discarded in soil, air and sea. The most important reason to cause “white pollution” is the chemical properties of plastics, such as polyethylene, which are difficult to be digested and degraded. On October of 2020, the European parliament approved to ban the use of disposable plastic products from 2021, in order to reduce the increasingly serious pollution of plastic material. Under this situation, reusing PCR (Post customer recycled) plastic material is urgent. One real situation is that many plastic bottle producer are trying to replace their single-layer extrusion blow molding machines by multi-layer machines.

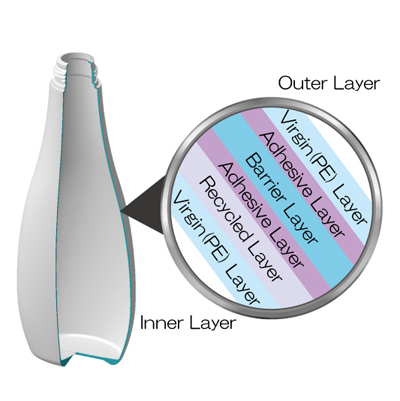

3.Combination of function necessities and environmental demand

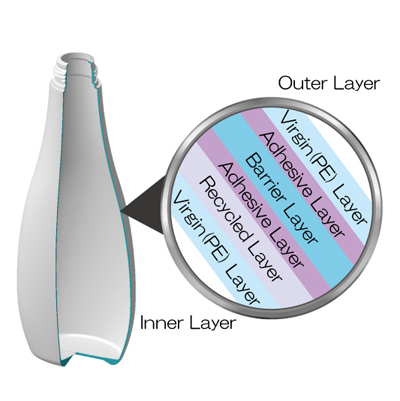

Except for food container, all hollow blow molded products can add a recycle layer to the original more single-layer or multi-layer functional plastic products. The conventional method is to include the recycle layer, but the current trend is that the recycle layer is in the middle.

50ml,100ml,200ml,500ml,1L (round bottle)

2L, 5L, 10L (with handle) The handle is blown separately and specially, so that it can pass the drop test smoothly (1M-1.2M)

Available models:

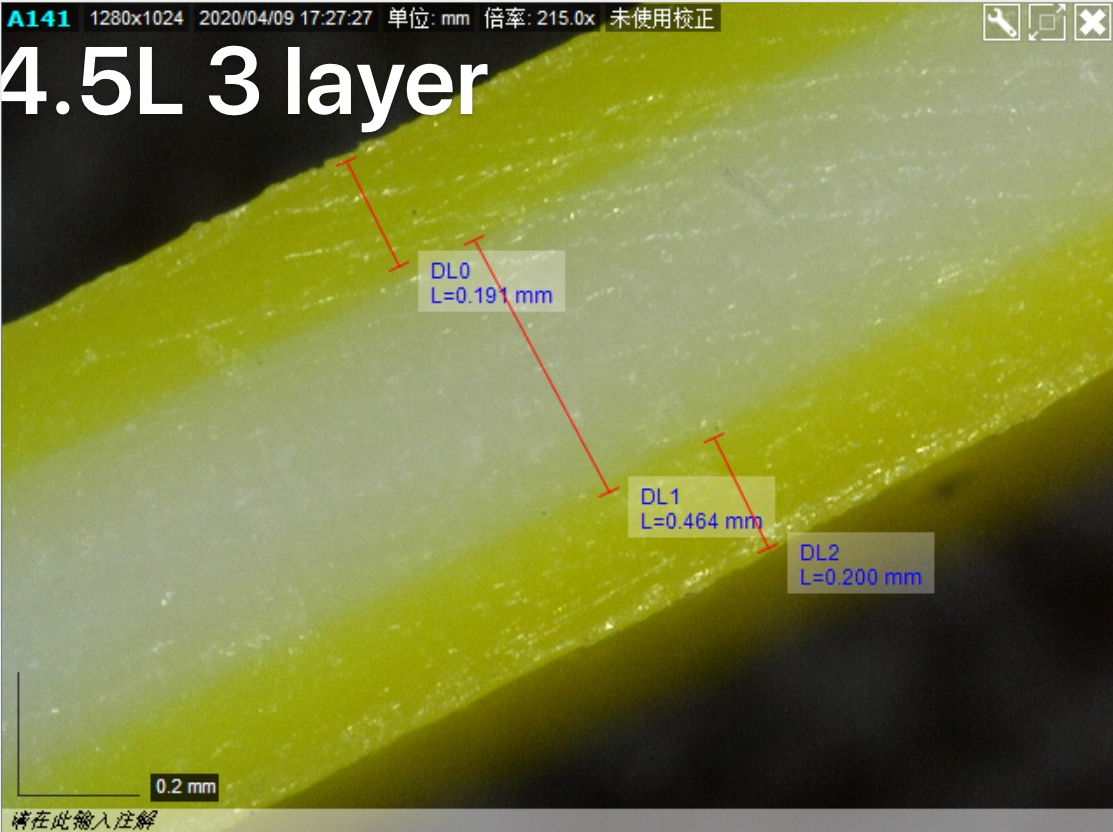

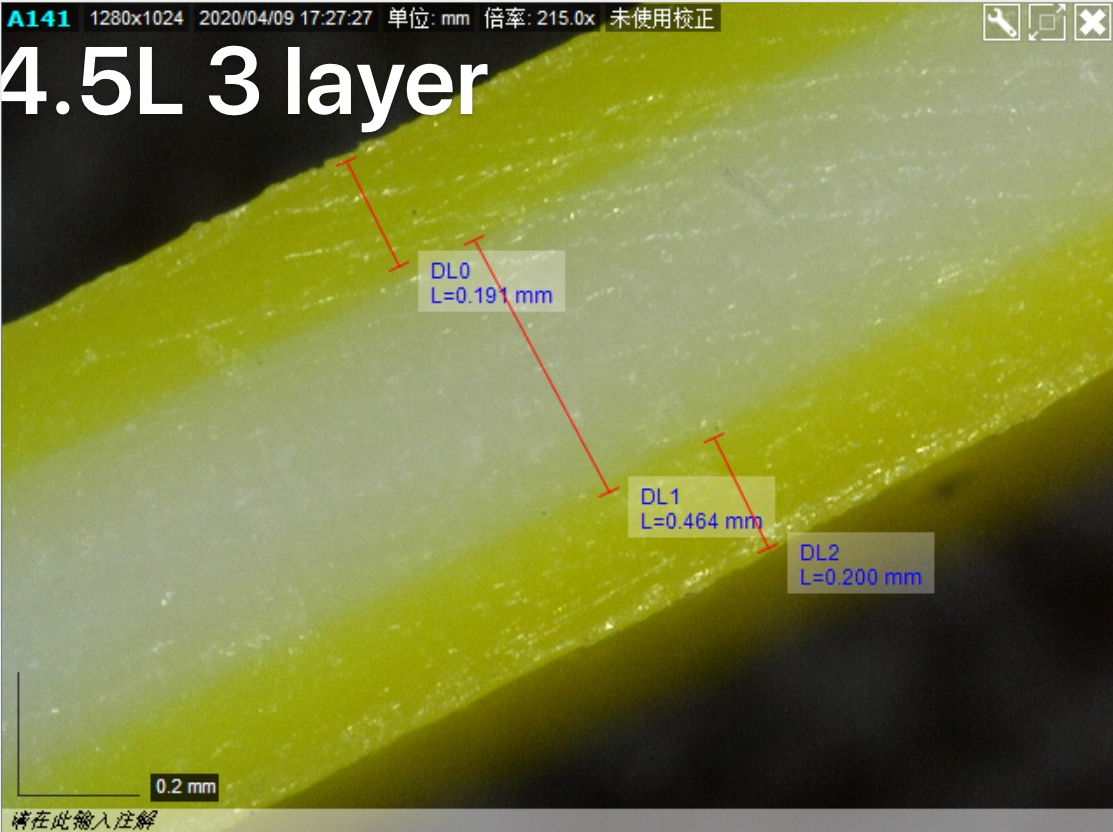

3 layers: outer layer new material / middle layer adhesive / inner layer barrier layer EVOH or PA 85%/5%/10%

4 layers: outer layer new material/secondary layer recycled material/secondary layer adhesive/inner layer EVOH or PA 25%/60%/5%/10%

5 layers: outer layer new material/second outer layer adhesive/intermediate layer barrier layer EVOH or PA/secondary inner layer adhesive/inner layer new material 40%/5%/10%/5%/40%

6 layers: outer layer new material/second outer layer recycle material/middle a layer adhesive/middle b layer barrier layer EVOH or PA/secondary outer layer adhesive/outer layer new material 20%/40%/5%/10% /5%/20%

Food bottles (canned bottles, ketchup bottles)

Optional models:

5 layers: outer layer new material / secondary outer layer adhesive / intermediate layer EVOH or PA / secondary inner layer adhesive / inner layer new material

Environmentally-friendly multilayer blow molding products and corresponding equipment

In addition to food packaging bottles, bottles and cans, all other products listed above can be added with a recycled material layer. The specific plan:

Double layer: new material on the outer layer/recycled material on the inner layer: 20%/80%

Three layers: new outer layer/returned middle layer/new inner layer 20%/60%/20% or 30%/40%/30% or others

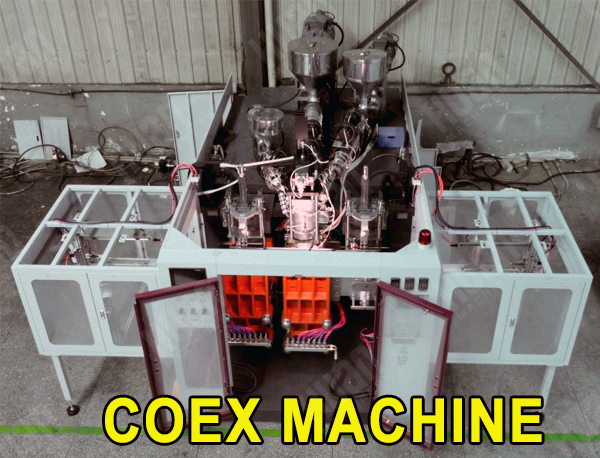

Our advantages in multilayer blow molding equipment

Since 2006, we have officially started to produce multi-layer hollow blow molding machines. We have more than 10 years of experience in manufacturing multi-layer co-extrusion equipment. Extrusion die poem is one of the most important parts that determine the quality of blow molded products. All die heads of our machine are independently developed, processed and assembled independently.